Graded porous vanadium oxide microspheres and preparation method and application thereof

A vanadium oxide, graded porous technology, applied in vanadium oxide, electrical components, battery electrodes, etc., can solve the problems of decreased electrode cycle stability, unfavorable large-scale application, and high temperature required for the reaction, and achieves enhanced cycle stability, The effect of improving charge transport efficiency and reaction safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

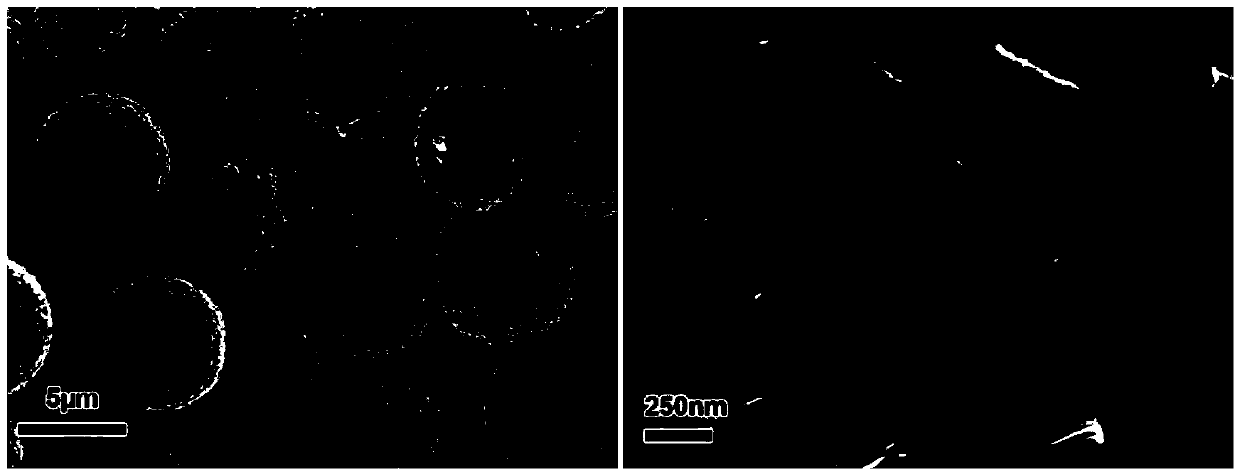

[0035] A method for synthesizing porous vanadium oxide microspheres, comprising the following steps:

[0036] (1) Add 0.5g of ammonium metavanadate to 200mL of ethylene glycol, place it on a water bath at 80°C and stir for 1 hour to form a uniform and transparent bright yellow liquid;

[0037] (2) continue to place the mixed solution described in step (1) on the oil bath, raise the temperature to 170°C, then react at a constant temperature of 170°C for 2 hours, condense and reflux during the reaction, and then cool naturally to obtain a blue-purple precipitate;

[0038] (3) Place the precipitate obtained in step (2) on a centrifuge and wash it six times with ethanol, the centrifuge speed is 6000r / min, and then dry the powder obtained by centrifugation in an oven at 60°C;

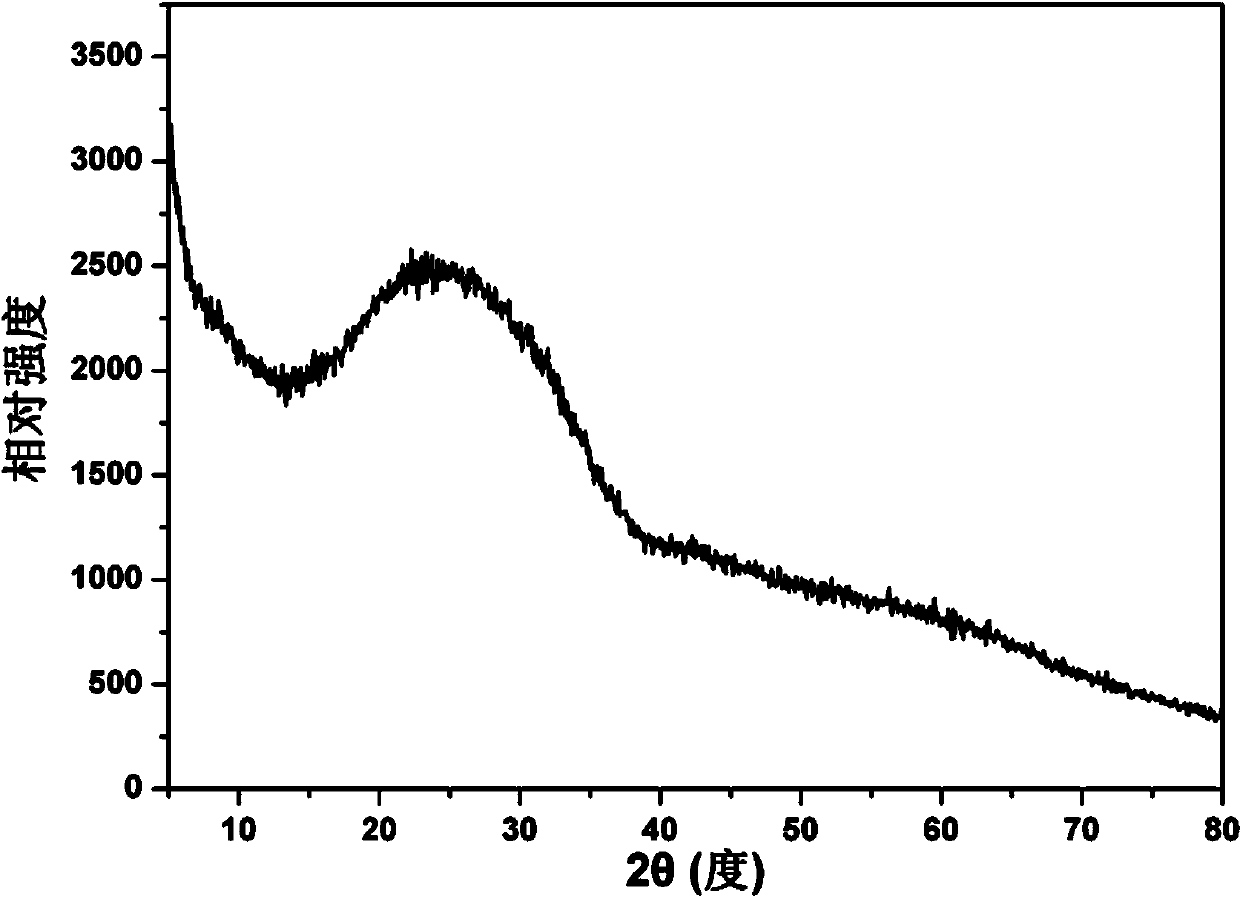

[0039] (4) Place the powder dried in step (3) in a tube furnace, start from room temperature, raise the temperature to 300°C at a rate of 1°C / min, and keep it at 300°C for 5 hours, the porous vanadium oxide ...

Embodiment 2

[0043] A method for synthesizing porous vanadium oxide microspheres, comprising the following steps:

[0044] (1) Add 0.5g of ammonium metavanadate to 400mL of ethylene glycol, place it on a water bath at 60°C and stir for 30min to form a uniform and transparent bright yellow liquid;

[0045] (2) continue to place the mixed solution described in step (1) on the oil bath, heat up to 170°C, then react at a constant temperature of 170°C for 1 hour, condense and reflux during the reaction, and then cool naturally to obtain a blue-purple precipitate;

[0046] (3) Place the precipitate obtained in step (2) on a centrifuge and wash it six times with ethanol, the centrifuge speed is 6000r / min, and then dry the powder obtained by centrifugation in an oven at 60°C;

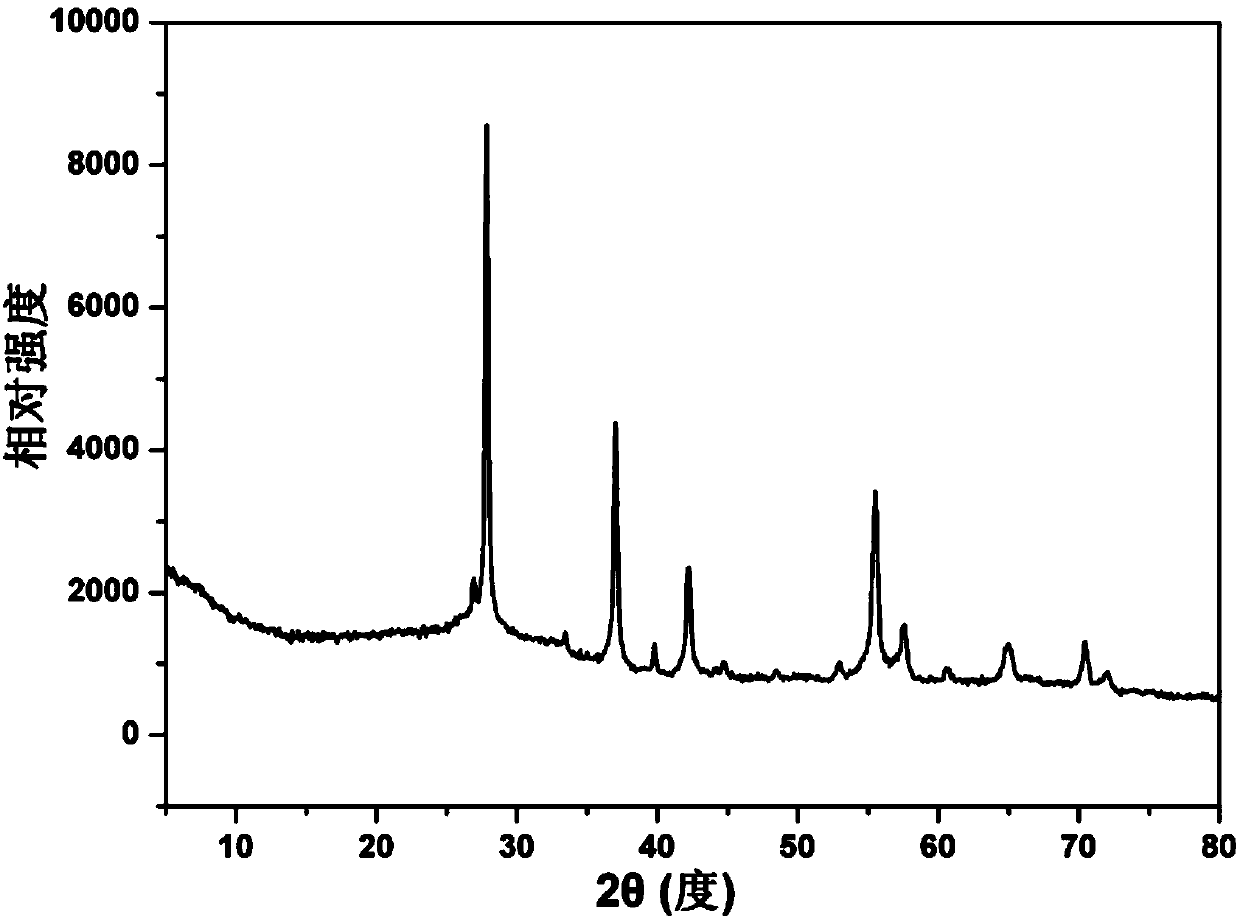

[0047] (4) Place the powder dried in step (3) in a tube furnace, start from room temperature, raise the temperature to 500°C at a rate of 1°C / min, and keep it at 500°C for 4 hours, the porous vanadium oxide microspheres . ...

Embodiment 3

[0051] A method for synthesizing porous vanadium oxide microspheres, comprising the following steps:

[0052] (1) Add 0.25g of ammonium metavanadate to 200mL of ethylene glycol, place it on a water bath at 80°C and stir for 2 hours to form a uniform and transparent bright yellow liquid;

[0053] (2) continue to place the mixed solution described in step (1) on an oil bath, heat up to 180°C, then react at a constant temperature of 180°C for 2 hours, condense and reflux during the reaction, and then cool naturally to obtain a blue-purple precipitate;

[0054] (3) Place the precipitate obtained in step (2) on a centrifuge and wash it six times with ethanol, the centrifuge speed is 6000r / min, and then dry the powder obtained by centrifugation in an oven at 60°C;

[0055] (4) Place the powder dried in step (3) in a tube furnace, start from room temperature, raise the temperature to 600°C at a rate of 1°C / min, and keep it at 600°C for 5 hours, the porous vanadium oxide microspheres ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com