High-alloy austenitic stainless steel microscopic structure, sigma intermediate-phase color corrosive agent and corrosion method

A technology of austenitic stainless steel and microstructure, which is applied in the field of high-alloy austenitic stainless steel microstructure and σ mesophase color etchant, can solve the problem of poor sample structure display effect, unsuitable for high-alloy stainless steel, high thermal processing performance Poor and other problems, to achieve the effect of good erosion effect, easy operation and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

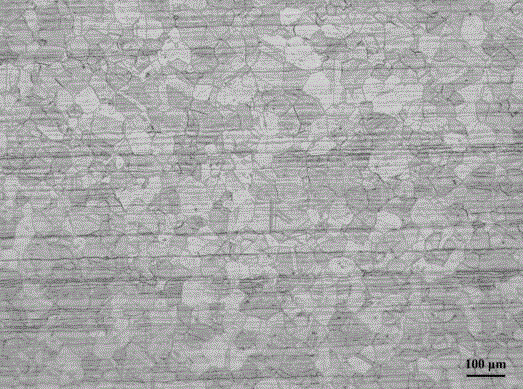

Embodiment 1

[0039] Corrosive formulation:

[0040] The present embodiment is made up of hydrochloric acid, nitric acid, potassium permanganate and deionized water, each component content is: potassium permanganate 0.6g; Hydrochloric acid (mass percentage concentration is 35%) 5ml; Nitric acid (mass percentage concentration is 35%) 68%) 5ml; deionized water 150ml; copper sulfate 0.12g.

[0041] Corrosive preparation:

[0042] Prepare the corrosive agent in the following order: first weigh 0.6g of potassium permanganate and 0.12g of copper sulfate, measure 5ml of hydrochloric acid (35% by mass), 5ml of nitric acid (68% by mass), and then measure 150ml of deionized water, mixed in a glass, stirred evenly with a glass rod, and left to stand for 15 minutes before use.

[0043] Metallographic Corrosion:

[0044] The samples were coarsely ground, finely ground, polished, washed with absolute ethanol and dried in accordance with conventional methods.

[0045] Fully immerse the prepared sample...

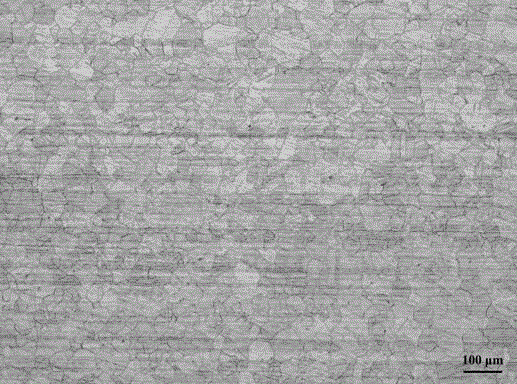

Embodiment 2

[0048] Corrosive formulation:

[0049] This embodiment is made up of hydrochloric acid, nitric acid, potassium permanganate and deionized water, each component content is: potassium permanganate 0.3g; Hydrochloric acid (mass percentage concentration is 35%) 10ml; Nitric acid (mass percentage concentration is 35%) 68%) 5ml; deionized water 150ml; copper sulfate 0.1g.

[0050] Corrosive preparation:

[0051]Prepare the corrosive agent in the following order: first weigh 0.3g of potassium permanganate and 0.1g of copper sulfate, measure 10ml of hydrochloric acid (35% by mass), 5ml of nitric acid (68% by mass), and then weigh 150ml of deionized water, mixed in a glass, stirred evenly with a glass rod, and left to stand for 15 minutes before use.

[0052] Metallographic Corrosion:

[0053] The samples were coarsely ground, finely ground, polished, washed with absolute ethanol and dried in accordance with conventional methods.

[0054] Fully immerse the prepared sample in the pr...

Embodiment 3

[0057] Corrosive formulation:

[0058] The present embodiment is made up of hydrochloric acid, nitric acid, potassium permanganate and deionized water, each component content is: potassium permanganate 1.0g; Hydrochloric acid (mass percentage concentration is 35%) 5ml; Nitric acid (mass percentage concentration is 35%) 68%) 15ml; deionized water 200ml; copper sulfate 0.12g.

[0059] Corrosive preparation:

[0060] Prepare the corrosive agent in the following order: first weigh 1.0g of potassium permanganate and 0.12g of copper sulfate, measure 5ml of hydrochloric acid (35% by mass), 15ml of nitric acid (68% by mass), and then weigh 200ml of deionized water, mixed in a glass, stirred evenly with a glass rod, and left to stand for 15 minutes before use.

[0061] Metallographic Corrosion:

[0062] The samples were coarsely ground, finely ground, polished, washed with absolute ethanol and dried in accordance with conventional methods.

[0063] Fully immerse the prepared sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com