Method for displaying two-phase grain boundary of duplex stainless steel

A technology of duplex stainless steel and grain boundary, which is applied in the preparation of test samples, etc., can solve the problems of not being able to display the two-phase grain boundary of duplex stainless steel, requiring electricity, and time-consuming, and achieving the effect of good microstructure observation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

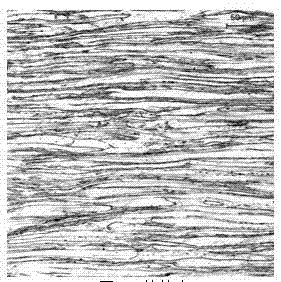

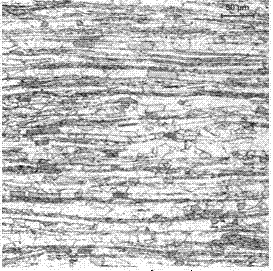

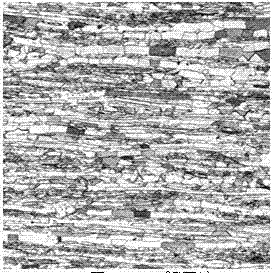

Image

Examples

Embodiment

[0025] The selected material is super duplex stainless steel 2906 plate, and the specific chemical composition (mass percentage%) is:

[0026] C 0.018, Si 0.56, Mn 0.96, Cr 29.38,

[0027] Ni 6.62, Mo 2.2, N 0.34,

[0028] The balance is Fe and unavoidable impurities.

[0029] The thickness of the steel plate is 15 mm, the size of the metallographic sample is a square of 15 × 10 × 15 mm, the state is hot-rolled and annealed at different solution temperatures, and the model of the metallographic analysis instrument is Lei DM4000.

[0030] The specific operation steps of this embodiment are as follows:

[0031] Ⅰ. Preparation of metallographic samples

[0032] (1) Metallographic samples are taken by machining and sawing. The size of the sample should be suitable for metallographic observation, usually a cylinder of φ15×20 mm (or a cube of 15×10×20 mm). High can cause microstructural changes or plastic deformation due to stress.

[0033] (2) Grind off the unnecessary sharp c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com