Method for quickly reducing height of converter bottom

A converter bottom and high technology, applied in the direction of manufacturing converters, etc., can solve the problems of the influence of the slag splashing process, the difficult control of the oxygen lance position, and the large fluctuation of the metal liquid level, so as to avoid safety production accidents and increase the soaking erosion time. , The effect of reducing the height of the furnace bottom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

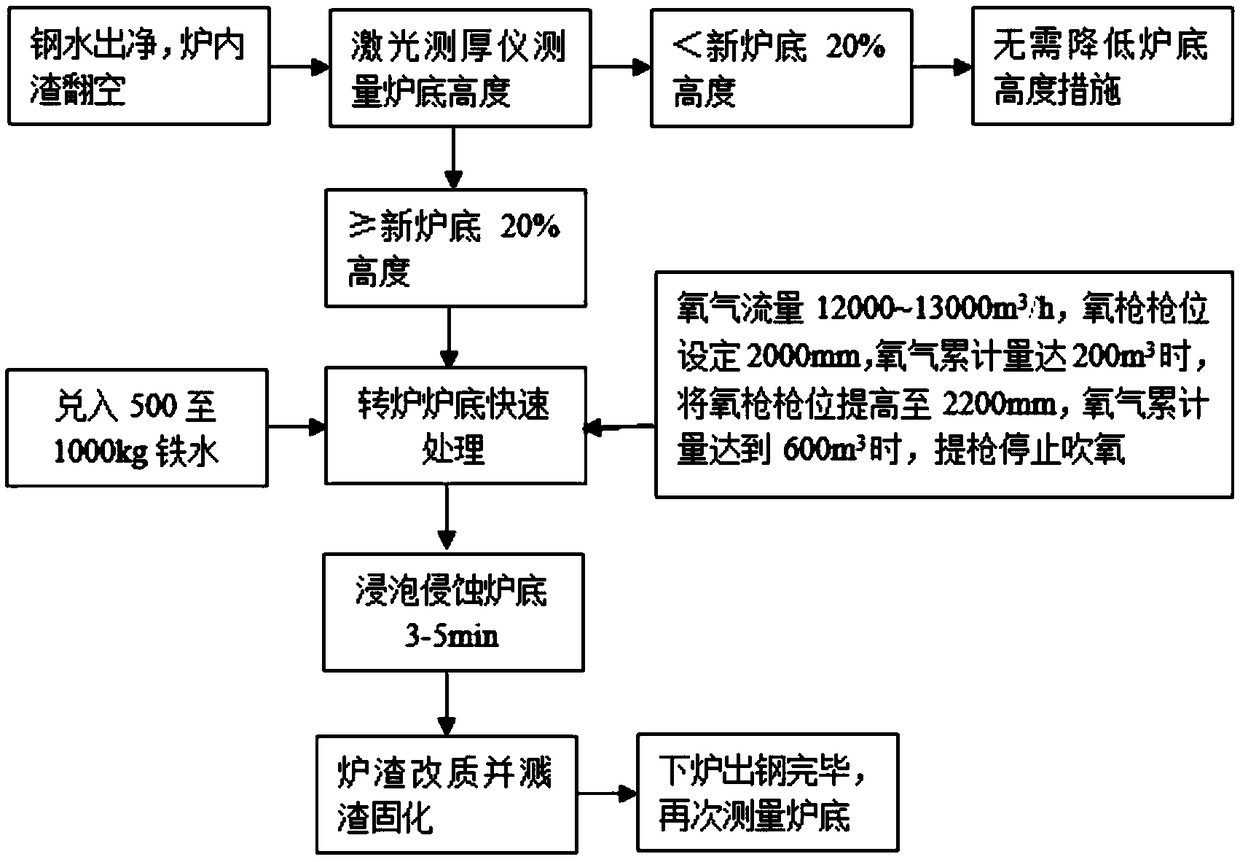

[0027] A method for rapidly reducing the bottom height of a converter, comprising the following steps:

[0028] 1) Measure the furnace bottom height

[0029] After tapping the steel in the upper furnace, the slag in the furnace is emptied, and the height of the furnace bottom is measured with a laser thickness gauge. When a new furnace is opened, the height of the furnace bottom is "0mm" as the benchmark, where "0mm" refers to the distance between the oxygen lance nozzles The metal liquid level of the molten pool is 1000mm; the measured furnace bottom height is +200mm, that is, the oxygen lance nozzle is 800mm away from the molten metal surface of the molten pool;

[0030] 2) Add molten iron

[0031] Add 800kg of molten iron into the converter;

[0032] 3) Oxygen blowing operation

[0033] Control oxygen flow rate 12000m 3 / h, the position of the oxygen lance is set to 2000mm. Press the "lower gun blowing" button, the oxygen gun will automatically drop to 2000mm and start...

Embodiment 2

[0043] A method for rapidly reducing the bottom height of a converter, comprising the following steps:

[0044] 1) Measure the furnace bottom height

[0045] After tapping the furnace, empty the slag in the furnace, and use a laser thickness gauge to measure the height of the furnace bottom. Taking the furnace bottom height "0mm" as the benchmark when opening a new furnace, the actual measured furnace bottom height is +400mm;

[0046] 2) Add molten iron

[0047] Add 1000kg of molten iron into the converter;

[0048] 3) Oxygen blowing operation

[0049] Control oxygen flow rate 13000m 3 / h, the position of the oxygen lance is set to 2000mm, press the button of "lower the gun blowing", the oxygen lance will automatically drop to 2000mm and open the oxygen, and the total amount of oxygen will reach 200m 3 Press and hold the "Oxygen Lance Up" button to increase the position of the oxygen lance to 2200mm, and the cumulative amount of oxygen reaches 600m 3, press the "Oxygen la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com