High-early-strength magnesium phosphate concrete and preparation method thereof

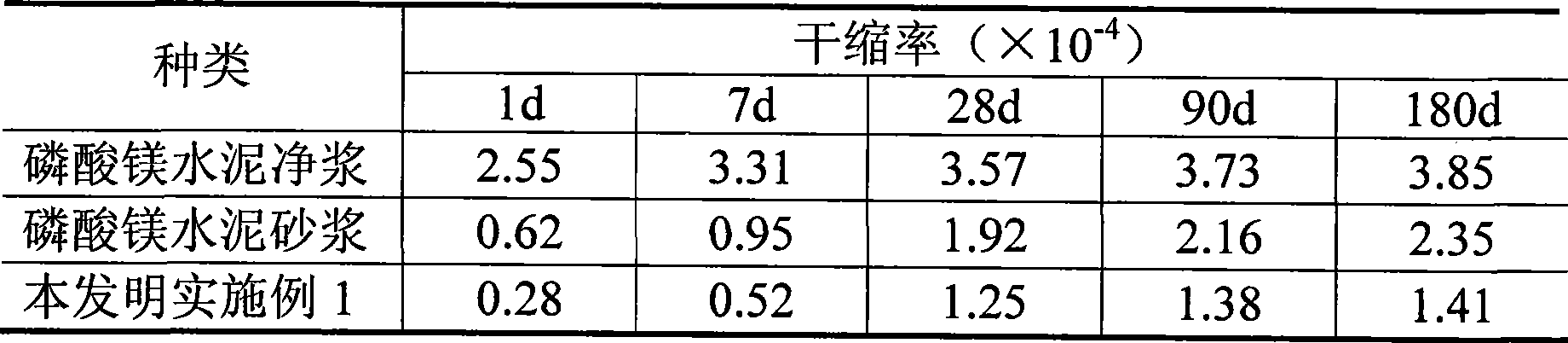

A technology of strong magnesium phosphate and concrete, which is applied in the field of building materials, can solve the problems of high material cost, unfavorable popularization and application, and fast setting speed, and achieve good resistance to seawater erosion, easy popularization and application, and low drying shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) according to the percentage by weight of each following component get the raw materials ready:

[0033] Magnesium oxide (specific surface area is 3500cm 2 / g): 23.3%

[0034] Potassium dihydrogen phosphate: 8.0%

[0035] Sodium dihydrogen phosphate: 3.7%

[0036] Boric acid: 1.9%

[0037] River sand (fineness modulus 2.6): 19.2%

[0038] Stones (limestone crushed stone with particle size less than 10mm) 36.1%

[0039] Water (tap): 7.8%

[0040] (2) Preparation of concrete

[0041] Start the concrete mixer, add magnesium oxide, boric acid, potassium dihydrogen phosphate, sodium dihydrogen phosphate, river sand and stones in sequence while stirring, and mix until uniform; finally, add tap water to the concrete mixer and stir quickly for 2 minutes to obtain concrete slurry .

[0042] (3) Performance testing

[0043] ①Mechanical performance testing

[0044] After pouring the concrete slurry for 2 hours, the measured compressive strength was 21.1MPa, the 1d com...

Embodiment 2

[0052](1) according to the percentage by weight of each following component get the raw materials ready:

[0053] Magnesium oxide (specific surface area is 4000cm 2 / g): 23.2%

[0054] Potassium dihydrogen phosphate: 9.2%

[0055] Sodium dihydrogen phosphate: 2.5%

[0056] Borax: 1.5%

[0057] Sodium polyphosphate: 0.3%

[0058] Zhanjiang sea sand (fineness modulus 1.8): 19.1%

[0059] Stones (broken pebbles with particle size less than 20mm): 35.9%

[0060] Water (Zhanjiang Seawater): 8.3%

[0061] (2) Preparation of concrete

[0062] Start the concrete mixer, add magnesia, borax, sodium polyphosphate, potassium dihydrogen phosphate, sodium dihydrogen phosphate, sea sand and pebbles in sequence while stirring, and mix until uniform; finally add sea water to the concrete mixer and stir quickly for 2 minutes , to get concrete slurry.

[0063] (3) Mechanical performance testing

[0064] After the concrete slurry was poured for 2 hours, the measured compressive strength...

Embodiment 3

[0066] (1) according to the percentage by weight of each following component get the raw materials ready:

[0067] Magnesium oxide (specific surface area is 4500cm 2 / g): 12.7%

[0068] Potassium dihydrogen phosphate: 8.7%

[0069] Sodium dihydrogen phosphate: 4.0%

[0070] Boric acid: 0.9%

[0071] Sodium polyphosphate: 0.3%

[0072] River sand (fineness modulus 2.6): 21.4%

[0073] Stones (limestone gravel with particle size less than 20mm): 44.5%

[0074] Water (tap water): 7.5%

[0075] (2) Preparation of concrete

[0076] Start the concrete mixer, add magnesium oxide, boric acid, sodium polyphosphate, potassium dihydrogen phosphate, sodium dihydrogen phosphate, river sand and stones in sequence while stirring, and mix until uniform; finally, add tap water to the concrete mixer and stir quickly for 2 minutes , to get concrete slurry.

[0077] (3) Mechanical performance testing

[0078] After the concrete slurry was poured for 2 hours, the measured compressive str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com