Rifle bore locking device for preventing misoperation and special wrench

A locking device and misoperation technology, applied in the direction of safety devices, offensive equipment, weapon accessories, etc., can solve the problems of potential safety hazards, lack of rifles to prevent reloading and firing, reloading and shooting misoperations, etc., to prevent false firing , Improve the safety of use, and the effect of reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

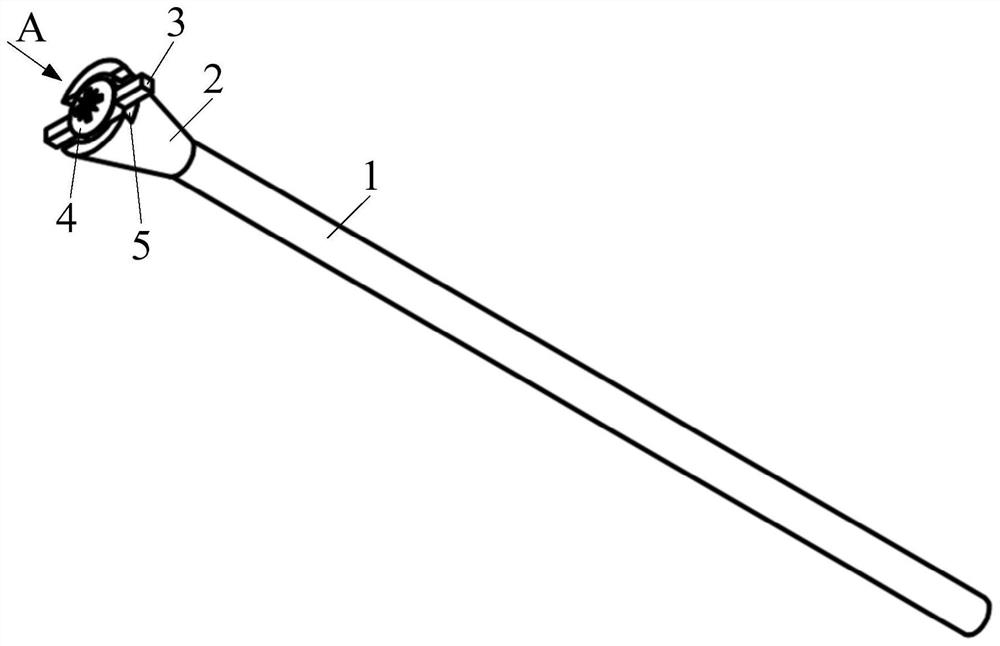

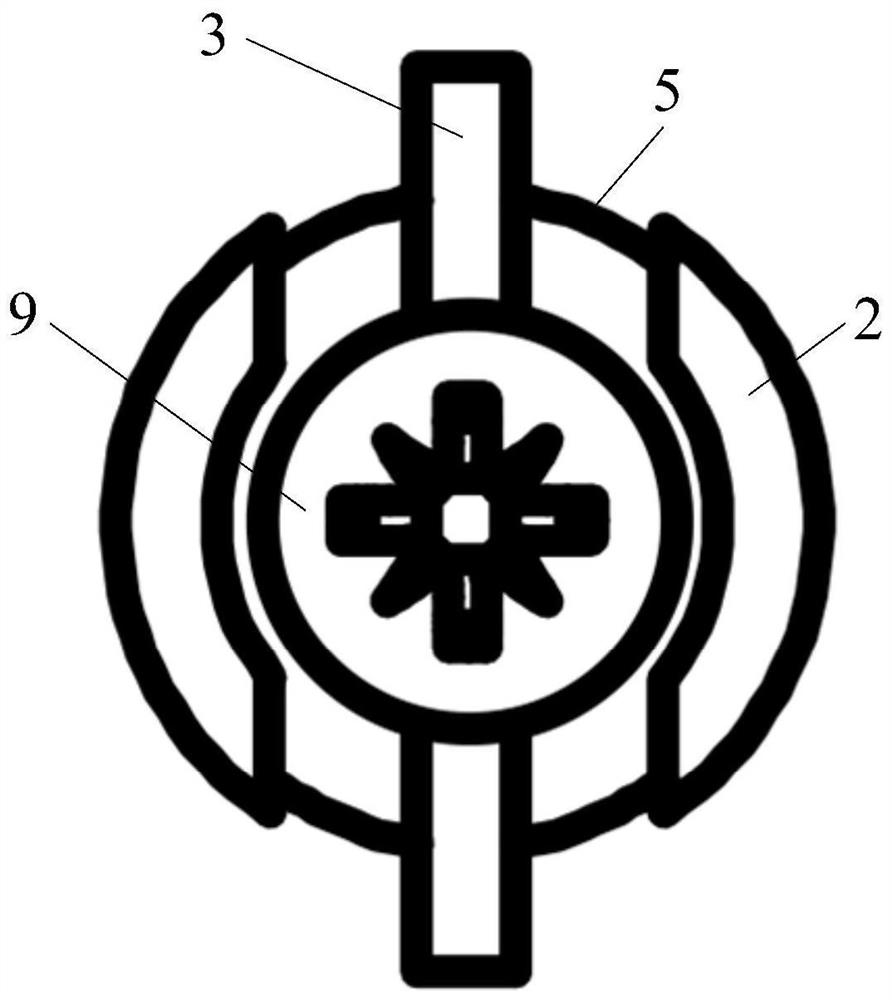

[0032] Such as figure 1 with figure 2 As shown in the structure, the chamber locking device includes a breech rod 1, a conical pressure plate 2, a locking pin 3 and a screw 4; Conical structure, and has a large-diameter end and a small-diameter end; the small-diameter end of the conical pressure plate 2 is fixedly connected to one end of the chamber rod 1, and the large-diameter end is threaded with the screw 4; the locking pin 3 is compressed by the screw 4 On the conical platen 2.

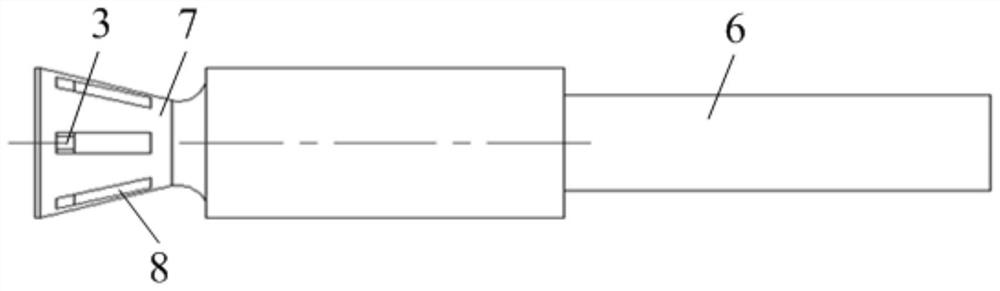

[0033] The above-mentioned rifle chamber locking device is used in the gun barrel 6 of the rifle to prevent misoperation, during specific use, such as image 3 As shown in the structure, the breech rod 1 extends from the end of the gun barrel 6 into the gun bore to block the gun bore, the conical pressure plate 2 matches the shape of the inner cavity of the flame arrester 7 at the end of the gun barrel 6, and passes through the conical pressure plate 2 and the flame arrester 7 are positioned,...

Embodiment 2

[0043] Additionally, if Figure 4 As shown in the structure, the embodiment of the present invention also provides a special wrench 11 used in conjunction with any one of the breech locking devices in the first embodiment above. . Special wrench 11 is used for the installation and dismounting of anti-theft screw 4, and the screw head 9 of anti-theft screw 4 is provided with the special-shaped groove 10 of irregular shape, can prevent adopting common wrench to carry out disassembly to anti-theft screw 4, realizes to the gun bore lock Control the disassembly and assembly of the stop device to prevent disassembly and installation by anyone without permission, and improve the safety of the rifle. The anti-theft screw 4 can be quickly disassembled by the special wrench 11, and all functions of the firearm can be quickly restored without affecting the speed of handling emergencies, and can effectively prevent misloading and misfiring during training and on duty It greatly improves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com