High polymer chemistry coal and rock mass reinforcer for coal mines

A polymer and reinforcing agent technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor scientific standardization, large toxic gas, unstable performance, etc., and achieve large compression deformation and foam toughness Large, functional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

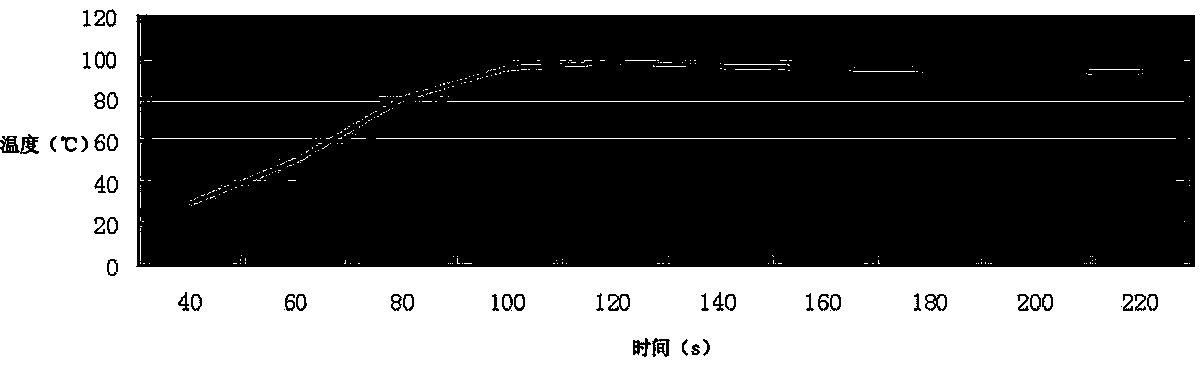

Image

Examples

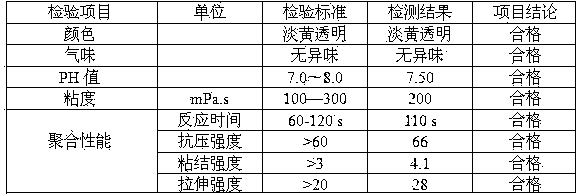

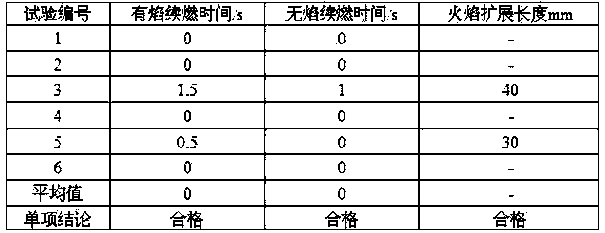

Embodiment 1

[0030] A polymer chemical coal rock reinforcement agent for coal mines, which consists of equal volumes of component A and component B, wherein component A is composed of polyether polyol, catalyst and flame retardant, and component B is multi-substrate Methyl polyphenyl polyisocyanate; the polyether polyol in component A is a polyether polyol with more than 3 functional groups, a hydroxyl value of 450-550, and a molecular weight of 300-500; the catalyst in component A is made of dibutyltin Composed of dilaurate and triethylenediamine, wherein the mass of dibutyltin dilaurate is 0.1% of the mass of polyether polyol, and the mass of triethylenediamine is 0.05% of the mass of polyether polyol; component A The flame retardant in is composed of dimethyl methyl phosphonate, tris(1,3-dichloro-2-propyl) phosphate and sodium silicate, wherein the quality of dimethyl methyl phosphonate is polyether 14% of the total mass of polyol and catalyst, the mass of tris(1,3-dichloro-2-propyl) ph...

Embodiment 2

[0035] A polymer chemical coal rock reinforcement agent for coal mines, which consists of equal volumes of component A and component B, wherein component A is composed of polyether polyol, catalyst and flame retardant, and component B is multi-substrate Methyl polyphenyl polyisocyanate; the polyether polyol in component A is a polyether polyol with more than 3 functional groups, a hydroxyl value of 450-550, and a molecular weight of 300-500; the catalyst in component A is made of dibutyltin Composed of dilaurate and triethylenediamine, wherein the mass of dibutyltin dilaurate is 0.1% of the mass of polyether polyol, and the mass of triethylenediamine is 0.05% of the mass of polyether polyol; component A The flame retardant in is composed of dimethyl methyl phosphonate, tris(1,3-dichloro-2-propyl) phosphate and sodium silicate, wherein the quality of dimethyl methyl phosphonate is polyether 14% of the total mass of polyol and catalyst, the mass of tris(1,3-dichloro-2-propyl) ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com