High-moisture filling material and preparation method thereof

A filling material and high water technology, which is applied in the field of preparation of cementitious materials, can solve the problems that efflorescence and high water filling materials cannot be widely used, and the material strength requirements are high, so as to improve the later strength, reduce the strength level, and reduce the processing difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

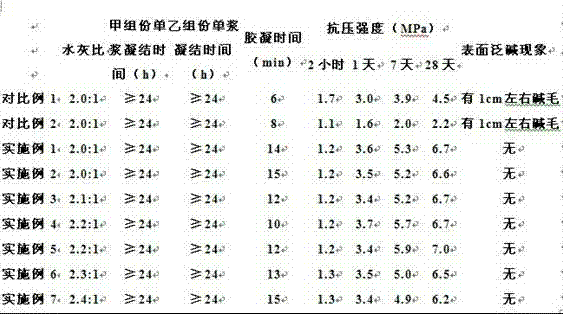

Examples

Embodiment 1

[0053] High water fill material, including Part A and Part B,

[0054] Wherein component A includes the following components:

[0055] Sulphoaluminate cement clinker 95wt% Aluminate cement clinker 2.7wt%

[0056] Tartaric acid 0.8wt% bentonite 0.8wt% cellulose ether 0.7wt%;

[0057] Component B includes the following components:

[0058] Anhydrite 55wt%, lime 15wt%, compound additive 30wt%,

[0059] The compound additives include

[0060] Suspending agent bentonite 10wt%

[0061] Inorganic matter NaNO 2 11wt% NaF 2wt% Li 2 CO 3 3wt%

[0062] Polymetaphosphoric acid 2wt% Organic compound Triethanolamine 1.5wt% Triisopropanolamine 0.5wt%.

[0063] The preparation method of high water filling material comprises the following steps:

[0064] The aluminate cement clinker is ground to a specific surface area of 400-500 m 2 / kg of powder, sulphoaluminate cement clinker, retarder and suspending agent are ground to a specific surface area of 600-700 m 2 / kg of powder...

Embodiment 2

[0082] High water fill material, including Part A and Part B,

[0083] Wherein component A includes the following components:

[0084] Sulphoaluminate cement clinker 52.4wt% Aluminate cement clinker 39wt%;

[0085] Tartaric acid 0.6wt% sepiolite 7wt% cellulose ether 1wt%;

[0086] Component B includes the following components:

[0087] Anhydrite 80wt% lime 10wt% compound additive 10wt%;

[0088] The compound additives include:

[0089] Suspending agent white carbon black 1.0wt% attapulgite 2.5wt% cellulose ether 0.5wt%;

[0090] Inorganic Ca(NO 3 ) 2 1.5wt% Na 2 CO 3 1.0wt% LiOH 2.0wt% (NH 4 ) 2 SO 4 1.5wt%;

[0091] The preparation method of high water filling material comprises the following steps:

[0092] Grind the aluminate cement clinker to a specific surface area of 400-500m 2 / kg of powder, sulphoaluminate cement clinker, retarder and suspending agent are ground to a specific surface area of 600-700 m 2 / kg of powder, then mix and stir evenly to ...

Embodiment 3

[0109] High water fill material, including Part A and Part B,

[0110] Wherein component A includes the following components:

[0111] Sulphoaluminate cement clinker 91.7wt% Aluminate cement clinker 5wt%

[0112] Citric acid 0.3wt% borax 1wt% white carbon black 2wt%;

[0113] Component B includes the following components:

[0114] Anhydrite 51wt% lime 20wt% compound additive 29wt%;

[0115] The compound additives include

[0116] Suspending agent bentonite 10wt%;

[0117] Inorganic matter NaNO 2 8wt% NaF 4wt% LiCl 1.5wt% Ca 2 NO 2 3wt% polymetaphosphoric acid 2wt%;

[0118] Organic compound Triisopropanolamine 0.5wt%;

[0119] The preparation method of high water filling material comprises the following steps:

[0120] The aluminate cement clinker is ground to a specific surface area of 400-500 m 2 / kg of powder, sulphoaluminate cement clinker, retarder and suspending agent are ground to a specific surface area of 600-700 m 2 / kg of powder, then mix and stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com