Aerated concrete building block produced by heavy metal-removed manganese carbonate tailing and manufacturing method thereof

A technology of manganese carbonate tailings and aerated concrete, which is applied in building construction, climate sustainability, building components, etc., can solve problems such as pollution, and achieve the effect of saving mineral resources, saving resources and saving land resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

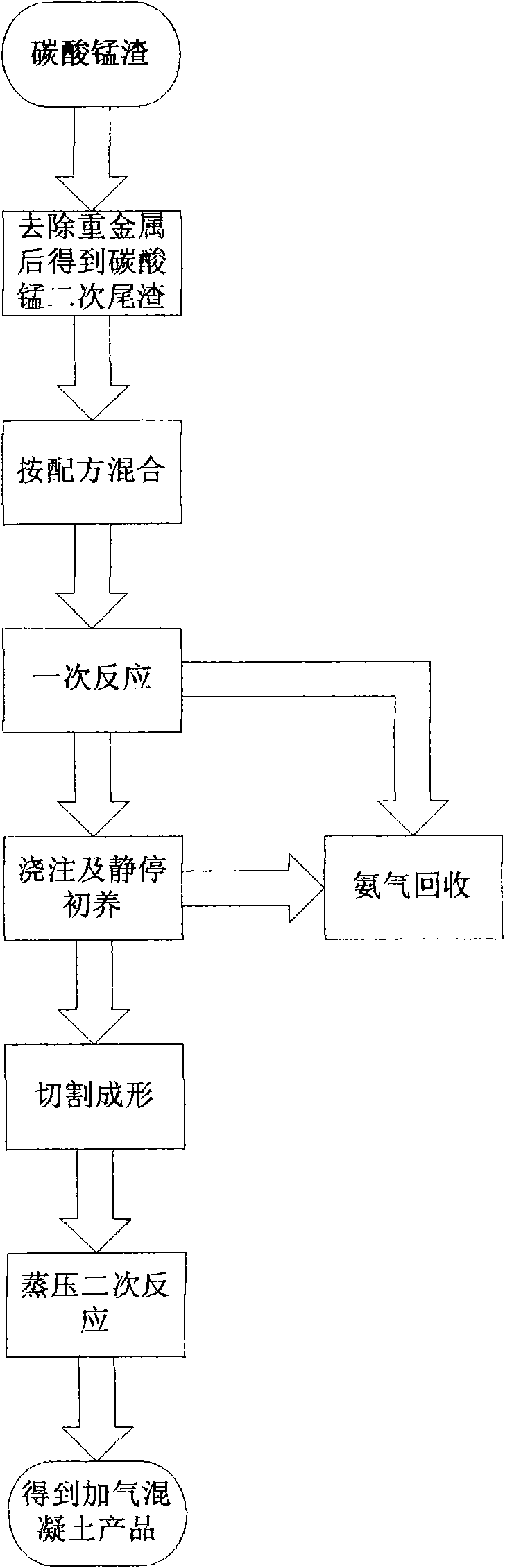

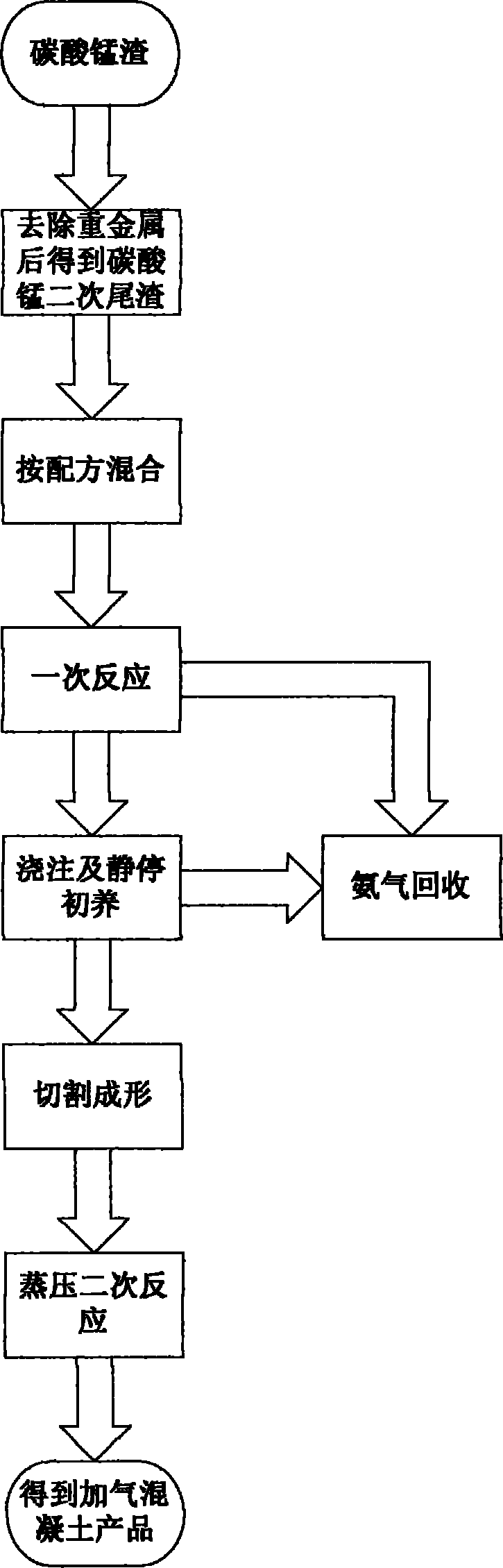

[0034] according to figure 1 As shown, a kind of aerated concrete block produced by manganese carbonate tailings after removing heavy metals, its raw material component weight percentage is as follows:

[0035] Manganese carbonate tailings after removal of heavy metals 30

[0036] Sand 46

[0037] lime 16

[0038] cement 8

[0039] Aluminum powder 0.003.

[0040] A method for producing aerated concrete block by using manganese carbonate tailings after heavy metal removal, the steps are as follows:

[0041] (1) The electrolytic manganese carbonate slag is sequentially screened, diluted and stirred, comprehensively sorted by using the difference in specific magnetic susceptibility coefficients of various substances in the manganese carbonate tailings, concentrate dehydration and drying, and concentrate packaging steps to obtain the ore grade concentrate and manganese carbonate secondary tailings after removing heavy metals;

[0042] (2) Mix one reaction

[0043]The mangan...

Embodiment 2

[0051] according to figure 1 As shown, a kind of aerated concrete block produced by manganese carbonate tailings after removing heavy metals, its raw material component weight percentage is as follows:

[0052] Manganese carbonate tailings after removal of heavy metals 50

[0053] Sand 28

[0054] lime 13

[0055] cement 9

[0056] Aluminum powder 0.01

[0057] A method for producing aerated concrete block by using manganese carbonate tailings after heavy metal removal, the steps are as follows:

[0058] (1) The electrolytic manganese carbonate slag is sequentially screened, diluted and stirred, comprehensively sorted by using the difference in specific magnetic susceptibility coefficients of various substances in the manganese carbonate tailings, concentrate dehydration and drying, and concentrate packaging steps to obtain the ore grade concentrate and manganese carbonate secondary tailings after removing heavy metals;

[0059] (2) Mix one reaction

[0060] The mangane...

Embodiment 3

[0068] according to figure 1 As shown, a kind of aerated concrete block produced by manganese carbonate tailings after removing heavy metals, its raw material component weight percentage is as follows:

[0069] Manganese carbonate tailings after removal of heavy metals 70

[0070] lime 17

[0071] cement 13

[0072] Aluminum powder 0.02

[0073] A method for producing aerated concrete block by using manganese carbonate tailings after heavy metal removal, the steps are as follows:

[0074] (1) The electrolytic manganese carbonate slag is sequentially screened, diluted and stirred, comprehensively sorted by using the difference in specific magnetic susceptibility coefficients of various substances in the manganese carbonate tailings, concentrate dehydration and drying, and concentrate packaging steps to obtain the ore grade concentrate and manganese carbonate secondary tailings after removing heavy metals;

[0075] (2) Mix one reaction

[0076] The manganese carbonate seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com