Multifunctional quick repair material for cement concrete pavements and preparation method thereof

A technology of cement concrete and repair materials, which is applied in the field of road repair, and can solve problems such as easy extrusion, shrinkage cracking, and low bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

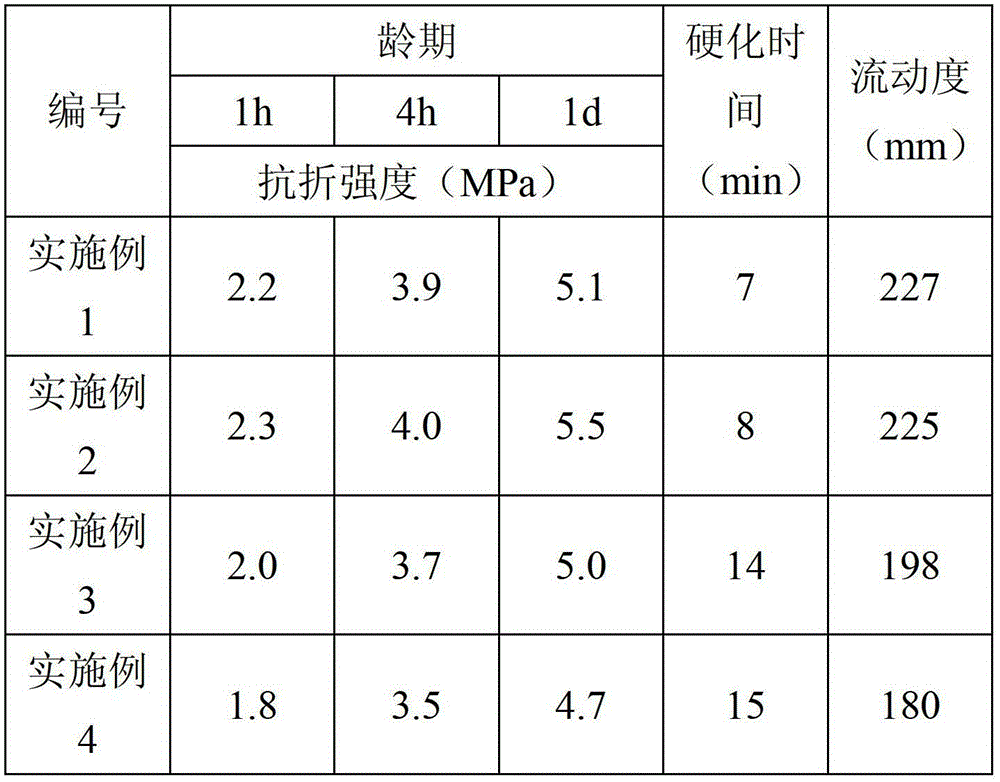

Examples

example 1

[0043] Cement concrete pavement multifunctional rapid repair material is prepared from the following materials in weight ratio: 26% magnesium oxide, 22% diammonium hydrogen phosphate, 12% boric acid, 10-20% aluminate cement, 5-10 % fly ash, 3-10% rubber powder, 1.5% polypropylene fiber, 1% redispersible latex powder, water-binder ratio is 0.25, silica sol replaces water consumption by 40%. The setting time of the fast repair material obtained by this formula can meet the needs of fast repair, and has good fluidity, and is suitable for grouting for fractures such as cracks and for grouting for vertical displacements such as voids at the bottom of the slab.

[0044] The construction method is as follows: clean up the dust, mud and oil stains in the diseased area that may affect the bond strength of the interface between the repair material and the diseased area to be repaired; remove loose and broken concrete blocks, and remove the narrow width Widen or deepen the cracks or surf...

example 2

[0046] Cement concrete pavement multifunctional rapid repair material is prepared from the following materials by weight: 30% magnesium oxide, 26% diammonium hydrogen phosphate, 14% boric acid, 15% aluminate cement, 8% pulverized coal Ash, 5% rubber powder, 1.5% polypropylene fiber, 1.5% redispersible latex powder, water-binder ratio is 0.28, silica sol replaces water consumption by 20%. The forming time of the rapid repair material obtained by this formula can meet the demand for rapid repair, and has good fluidity, which is suitable for grouting for fracture defects such as cracks and grouting for vertical displacement defects such as voids at the bottom of the slab. Refer to Example 1 for the construction method.

example 3

[0048] Cement concrete pavement multifunctional rapid repair material is prepared from the following materials by weight: 33% machine-made sand or natural fine sand, 20% magnesium oxide, 17% diammonium hydrogen phosphate, 10% boric acid, 10% aluminum Salt cement, 5% fly ash, 3% rubber powder, 1% polypropylene fiber, 1% redispersible latex powder, the water-cement ratio is subject to better fluidity, and the amount of silica sol is water 40% of the amount. The rapid repair material obtained by this formula can meet the needs of rapid repair in setting time, has good fluidity, and is suitable for filling height difference for vertical displacement diseases such as staggered platforms and repairing surface layer diseases such as potholes. Refer to Example 1 for the construction method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com