Restrained damping heat and sound insulation device and preparation method thereof

A technology of heat insulation and sound insulation and restraint damping, which is used in armored vehicles, transportation and packaging, motor vehicles, etc., can solve the problem that no effective protective measures are taken for the heat insulation of the power compartment, the heat insulation and sound insulation performance cannot meet the requirements, and the body cannot meet the requirements. Weight reduction requirements and other issues, to achieve the effect of excellent thermal insulation and sound insulation, ensuring thermal insulation and sound insulation, and strong anti-vibration ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

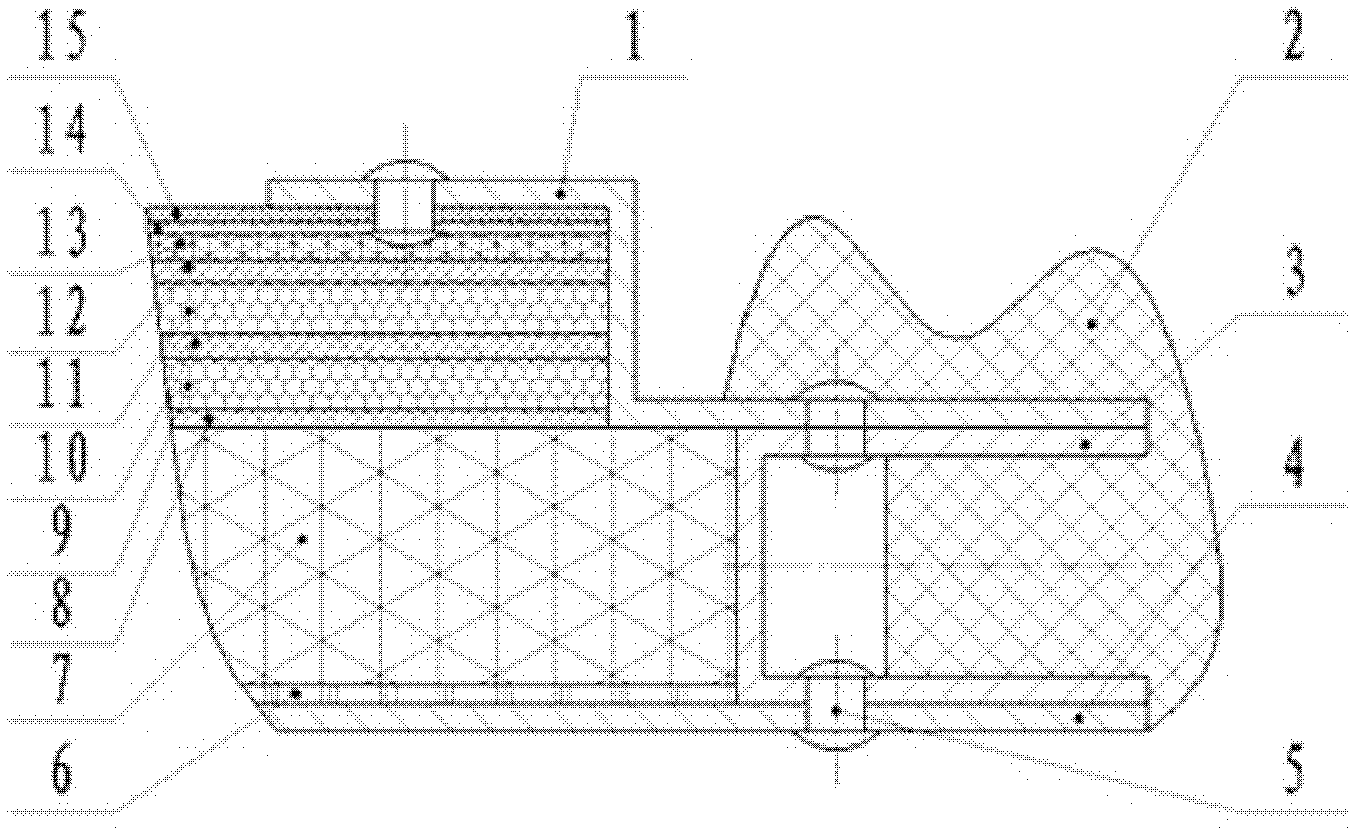

[0025] Embodiment 1, a constrained damping heat insulation and sound insulation device is composed of a sealed shell and a heat and sound insulation functional composite material filled in the shell. The shell includes a panel 4, a reinforcing plate 14 and a The clamping strip 3 is connected with the clamping strip 1 between the reinforcing plate 14 and the clamping strip 3; the heat-insulating and sound-insulating functional composite material includes a heat-insulating layer, a sound-insulating layer and a damping layer arranged alternately.

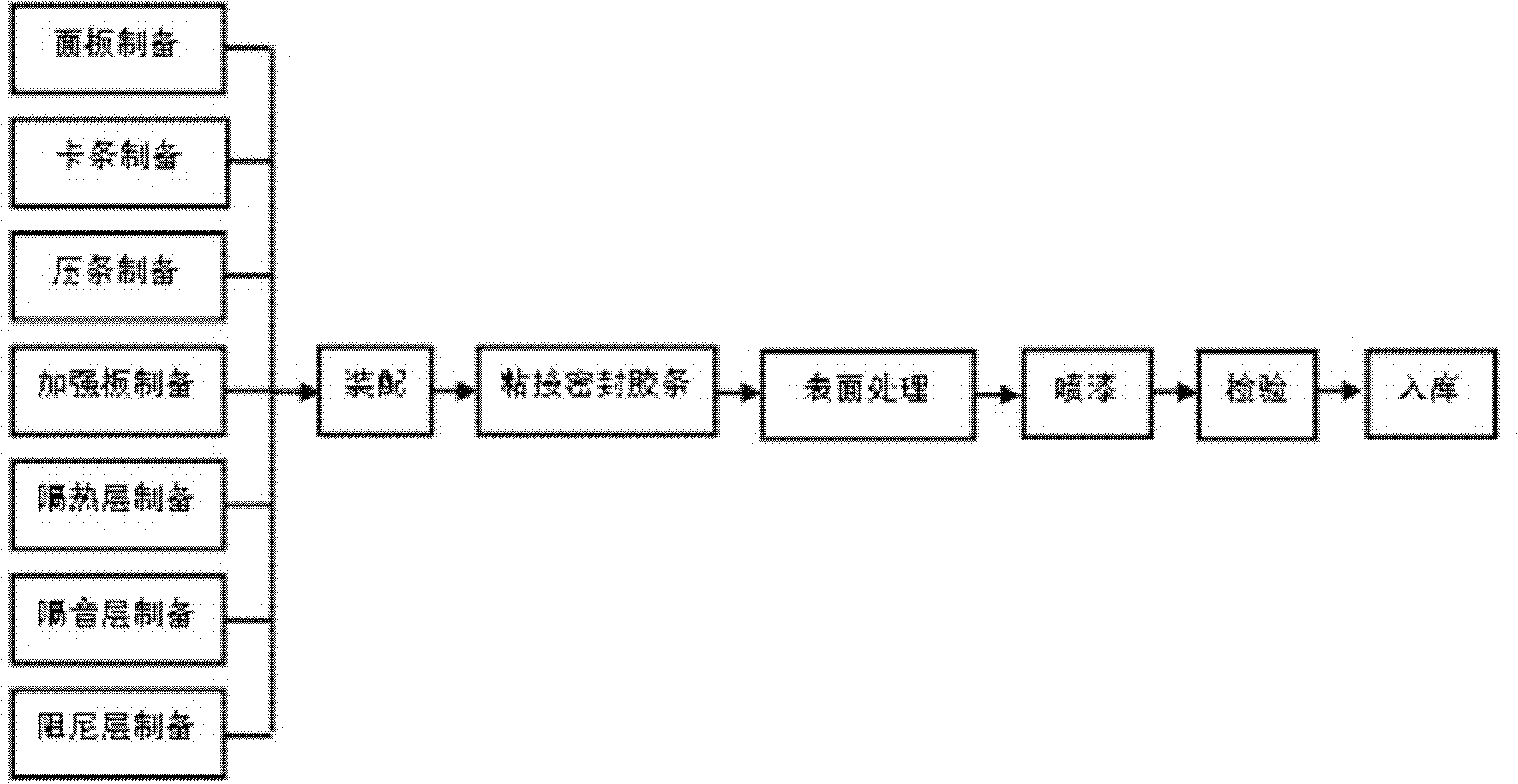

[0026] The preparation method of the constrained damping heat insulation and sound insulation device: the shell is made of light metal and alloy plates, and is formed by sheet metal forming technology; The layer is composed of ceramic fiber porous loose material and light metal mesh, the damping layer is composed of rubber plate or high pressure polyethylene plate, the sealing strip is made of high temperature resistant, anti-aging, hig...

Embodiment 2

[0027] Embodiment 2, a constrained damping heat insulation and sound insulation device is composed of a sealed shell and a heat and sound insulation functional composite material filled in the shell. The shell includes a panel 4, a reinforcing plate 14 and a The clamping strip 3, the reinforcing plate 14 and the clamping strip 4 are connected by the pressing strip 1; the heat-insulating and sound-insulating functional composite material includes a heat-insulating layer, a sound-insulating layer and a damping layer arranged alternately, and the heat-insulating layer includes a heat-insulating layer I8, a heat-insulating layer Layer II10, heat insulation layer III12 and heat insulation reflective layer 13, the sound insulation layer includes heat insulation and sound absorption layer 7 and mesh sound absorption layer 15, the damping layer includes damping layer I6, damping layer II9 and damping layer III11; bead 1 is Z Type bead, panel 4, reinforcing plate 14, clip 3 and bead 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com