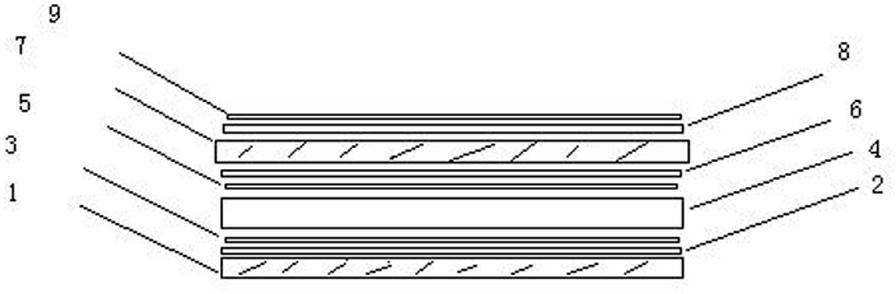

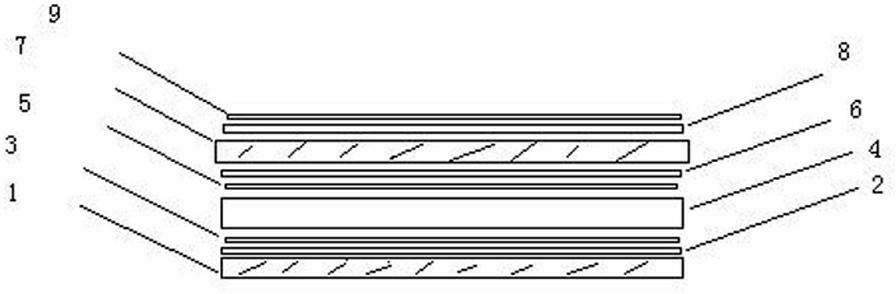

Multilayer composite board for construction and manufacturing method thereof

A production method and composite board technology, which can be applied to buildings, building components, building structures, etc., can solve the problems of poor waterproof effect, poor thermal insulation and sound insulation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] A waterproof layer is laid on the upper and lower surfaces of the polyurethane foaming mould. The thickness of the waterproof layer is controlled at 0.06mm. The two opposite surfaces of the waterproof layer are respectively coated with polyurethane adhesive. The waterproof layer has a diameter of 25 microns and a length of The 6 mm impermeable polypropylene staple fiber is flocked on the two surfaces of the impermeable polypropylene core film at a ratio of 3.5 million fibers per square meter. The flocking is flocked by an electrostatic machine. The core film is made of polypropylene material and is made of non-woven fabric by spunbonding; the middle distance between the upper and lower molds is controlled to 30mm, and the foaming material is injected into the middle cavity of the mold. The ratio of the main components of polyether polyethanol and isocyanate is 1:1, the foaming temperature is 35℃, the foaming and stabilization time is 30 minutes, and the final polyurethane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com