Method for continuously producing environment-protection light gypsum wall material by using industrial residue

A technology for industrial waste residue and wall materials, applied in chemical instruments and methods, manufacturing tools, solid waste management, etc., to achieve strong competitiveness, good economic benefits, and good sound insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

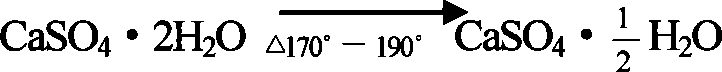

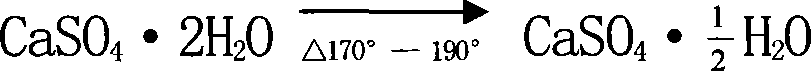

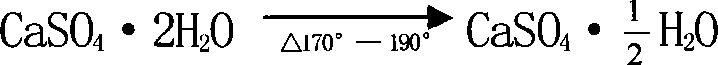

[0020] In the first step, phosphogypsum is mixed with a certain amount of lime to carry out acid-base neutralization reaction and three-stage purification is carried out in the form of backflow with clean water. The size of the purification outer tank is 3000 mm × 400 mm. Then it is centrifugally dehydrated and air-dried (at this moment, the cement retarder is made, and the content of its main element is: sulfur trioxide is greater than 40% and water of crystallization is greater than 12%). Make the attached water in phosphogypsum less than 10-15%, P 2 o 5 ≤0.3%, F≤0.1%. Add 30% natural gypsum ore to change the size and structure of the particles in the mixture to ensure the smooth flow of the mixture when entering the calcining kiln, so as to meet the production line operation requirements. Make the temperature of the calcining kiln reach 170°C-190°C again so that the mixed raw materials are composed of:

[0021]

[0022] And the attached water is less than 3%, it can s...

Embodiment 2

[0026] Embodiment 2: embodiment is identical with embodiment, repeats no more at this, and its raw material and processing step and condition are as follows:

[0027] 1. Taking phosphogypsum discharged from an enterprise in Kunming City, Yunnan Province as raw material, other chemical components (mass fraction) were tested, as shown in the table below:

[0028] Element

SO 3

CaO

SiO 2

F

Mg

Al 2 o 3

Fe 2 o 3

total

content

36.46

30.80

5.90

0.30

0.04

0.05

0.21

Element

P 2 o 5

Na 2 o

K 2 o

TiO 2

m 2 o

burn vector

100

content

1.27

0.10

0.09

0.05

0.01

24.02

[0029] 2. Clean, dehydrate and dry phosphogypsum with clear water for three times, then mix it with 30-40% natural gypsum ore, calcinate at 170°C°-190°C, and grind it to 100-150 mesh to obtain β-type building gypsum The composition of the powder has chang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com