Suspended film hollow glass, manufacturing method, continuous production device and application

A production method and technology of hanging film, applied in the application, parallel glass structure, window glass installation, etc., can solve the problems of affecting heat insulation effect, unable to realize mechanization and automatic production, affecting product qualification rate and production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

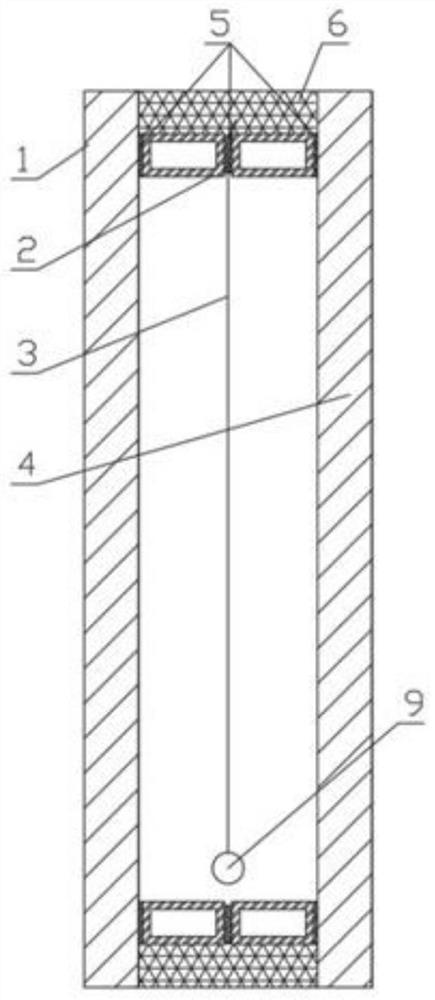

[0193] Such as figure 1 As shown, the two-glass two-chamber suspension film insulating glass provided by the present invention includes a front glass 1, a spacer frame 2, a suspension film 3, a rear glass 4, a sealant 5, a structural glue 6 and a bottom bar 9, the front glass 1 and the rear glass The glass 4 is placed in parallel, and a spacer frame 2 is bonded and fixed by a sealant 5 at the corresponding positions around the front glass 1 and the rear glass 4. The sealant 5 is generally butyl glue, and the upper ends of the two spacer frames 2 are passed through the sealant. 5 Adhesively fix a suspension film 3, so that the suspension film 3 is suspended in the cavity between the front glass 1 and the rear glass 4, and form a hollow cavity with the front glass 1 and the rear glass 4 respectively, and the lower end of the suspension film 3 is fixed Connect a bottom bar 9, rely on the gravity of the bottom bar 9 to tighten the suspension film 3, or install springs or magnets a...

Embodiment 2

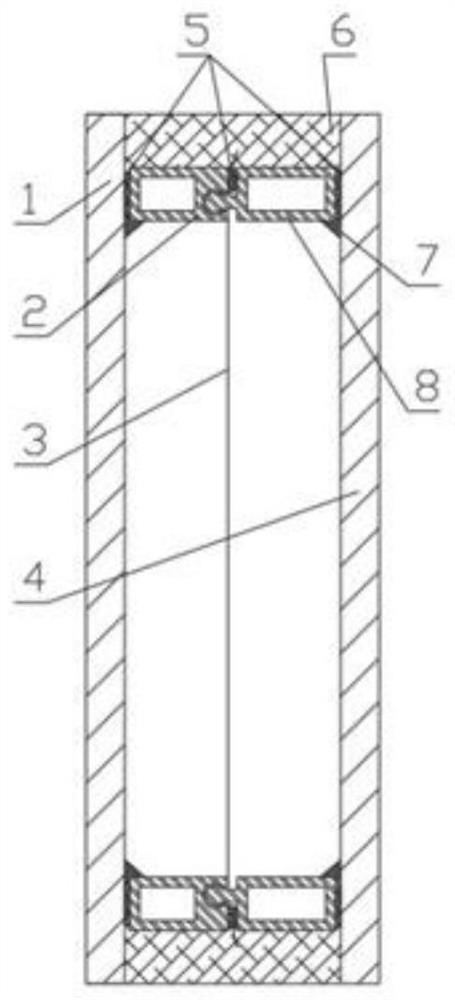

[0195] Such as figure 2 As shown, the two-glass two-cavity film-suspended insulating glass provided by the present invention includes a front glass 1, a spacer frame 2, a film-suspended film 3, a rear glass 4, a sealant 5, a structural glue 6, a quick-drying glue 7 and a stretch film frame 8 , the front glass 1 and the rear glass 4 are placed in parallel, and a spacer frame 2 and a stretch film frame 8 are respectively bonded and fixed at the corresponding positions of the front glass 1 and the rear glass 4 by a sealant 5, and the spacer frame 2 has a groove, a stretch film There are convex lines on the frame 8, the grooves and the convex lines can be fitted together, the grooves and the convex lines are biased towards the inner ring of the frame, the outside of the groove is the place where the suspension film 3 is connected and fixed, and the outside of the convex lines is glued and the bonding place; the sealant 5 generally adopts butyl glue, and the quick-drying glue 7 is...

Embodiment 3

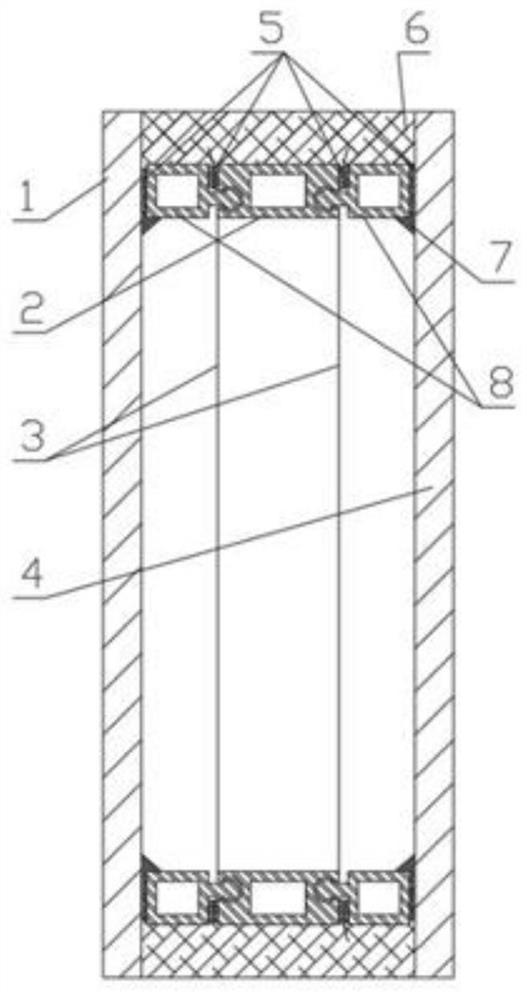

[0197] Such as image 3 As shown, the two-glass three-cavity film-suspended insulating glass provided by the present invention includes a front glass 1, a spacer frame 2, a film-suspended film 3, a rear glass 4, a sealant 5, a structural glue 6, a quick-drying glue 7 and a stretch film frame 8 A stretch film frame 8 is bonded and fixed by sealant 5 at the corresponding positions around the front glass 1 and the rear glass 4 respectively. After the stretch film frame 8 is flattened, glue is applied to the contact between the inner ring of the stretch film frame 8 and the glass. machine with a 45-degree angle to apply the quick-drying glue 7, and the quick-drying glue 7 can use acrylic instant-drying glue to make the stretch film frame 8 fast and firmly fixed on the glass; Adhesive 5 bonds and fixes a suspension film 3, and the suspension film 3 can also be directly welded on the spacer frame 2 by welding. The sealant 5 generally adopts butyl glue; the spacer frame 2 has grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com