Reinforcement honeycomb panel filled with polyurethane combined material and preparation method thereof

A polyurethane composite material, reinforced technology, applied in chemical instruments and methods, building components, lamination and other directions, can solve the problems of poor sound insulation and heat insulation performance, no moisture resistance, insufficient strength, etc., and achieves environmental protection and strength. Large, wood-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

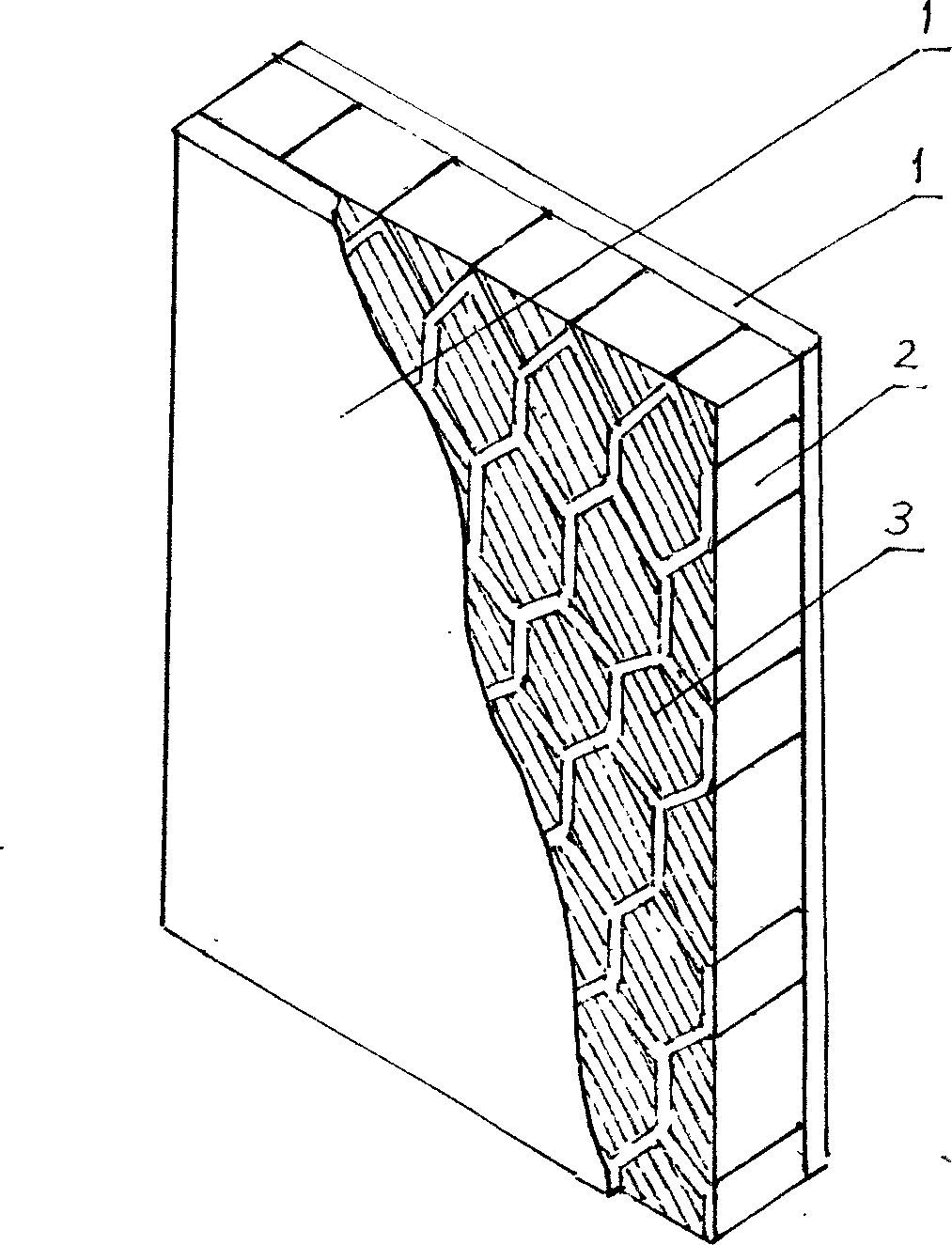

[0015] The specific implementation method is as follows: the reinforced honeycomb plate filled with polyurethane composite material includes panel 1, honeycomb core 2 and polyurethane composite filler 3; honeycomb core 2 is located between two panels 1; polyurethane composite filler 3 is filled in In the honeycomb core 2; the honeycomb core 2 and the panel 1 are bonded with polyurethane composite material. The polyurethane composite filler 3 comprises polyurethane and polyester, and its weight ratio is polyurethane:polyester=1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com