Heat-sound insulating lightweight concrete composite wallboard and manufacturing method thereof

A lightweight concrete, heat and sound insulation technology, applied in sound insulation, manufacturing tools, building construction, etc., can solve problems such as large void ratio, low density of heat and sound insulation materials, and unsatisfactory heat and sound insulation performance of composite concrete wall panels , to achieve the effects of simple manufacturing process, increased flexural strength, and simplified positioning operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

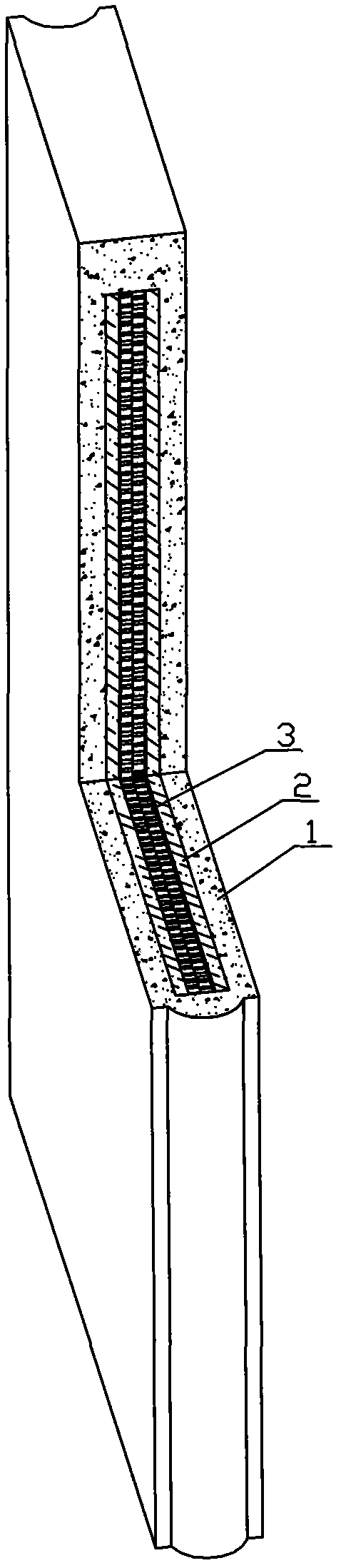

[0035] refer to figure 1 and image 3 , a heat-insulating and sound-insulating lightweight concrete composite wallboard, comprising a lightweight aggregate concrete layer 1 and a heat-insulating and sound-insulating layer placed inside the light-aggregate concrete layer 1, the heat-insulating and sound-insulating layer comprising two fiber-reinforced cement sheets 2 and A heat and sound insulation material layer 3 filled between two fiber reinforced cement sheets 2 .

[0036] In this embodiment, the heat and sound insulation material layer 3 is mineral wool (or rock wool or glass wool), the fiber reinforced cement sheet 2 is a glass fiber reinforced cement concrete sheet with a thickness of 5-8mm, and the light aggregate concrete layer 1 is Polystyrene foam particle cement concrete, the compressive strength is greater than 3.5Mpa, and the thickness (that is, the thickness of the wallboard) is 100mm.

[0037] The bending load of this wallboard is greater than 1.5 times its ow...

Embodiment 2

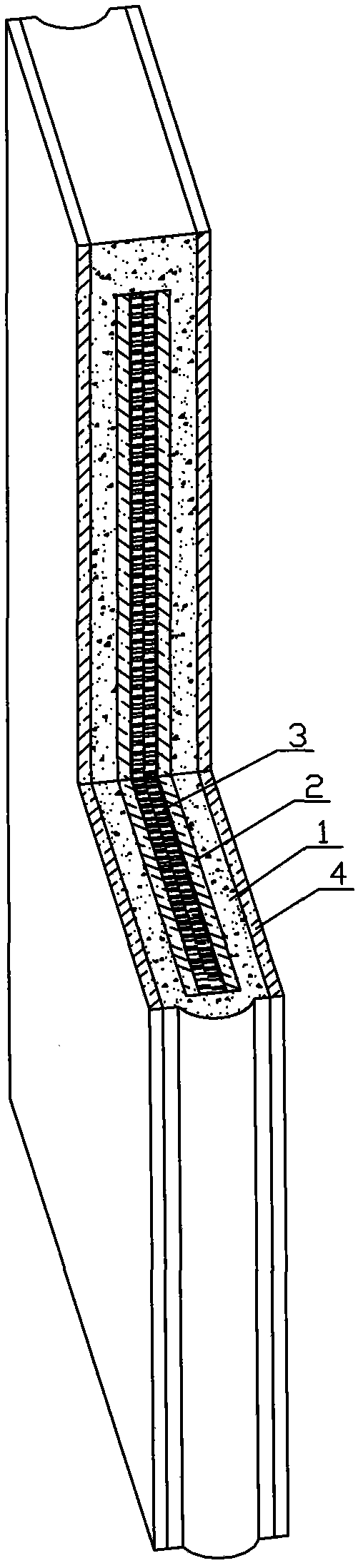

[0039] refer to figure 2 and Figure 5 , The difference between this embodiment and Embodiment 1 is that a surface concrete thin plate 4 is also combined outside the light aggregate concrete layer 1 .

[0040] In this embodiment, the heat and sound insulation material layer 3 is a combination of a glass wool layer 32 and a rock wool board 31, and the fiber reinforced cement sheet 2 and the surface concrete sheet 4 are both glass fiber reinforced cement concrete sheets with a thickness of 5-10 mm. , the light aggregate concrete layer 1 is lightweight ceramsite cement concrete, the compressive strength is greater than 5Mpa, and the thickness (ie, the thickness of the wallboard) is 150mm.

[0041] The bending load of this wallboard is greater than 1.5 times its own weight, the axial compressive strength is greater than 3.5Mpa, the heat transfer coefficient is less than 1W / m.K, and the air sound insulation RW>50db.

Embodiment 3

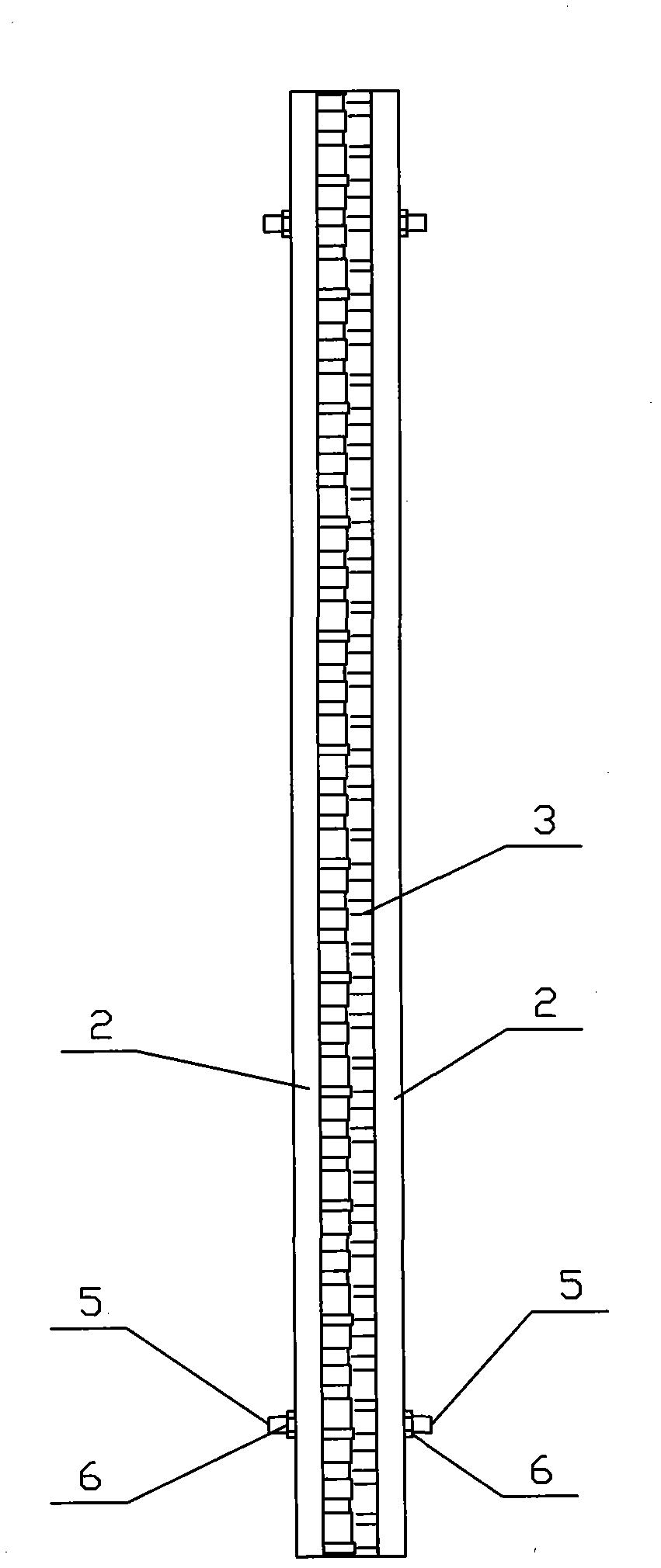

[0043] refer to figure 1 , figure 2 and image 3 , a heat and sound insulation lightweight concrete composite wall panel manufacturing process, the manufacture of a composite panel with a heat and sound insulation layer and a lightweight aggregate concrete layer 1, the heat and sound insulation layer includes two fiber reinforced cement sheets 2 and filled in two The heat and sound insulation material layer 3 between the fiber reinforced cement sheets 2, which comprises the following process steps:

[0044] A. Make a heat and sound insulation layer, and use connectors to fix and connect two fiber reinforced cement sheets 2 filled with a heat and sound insulation material layer 3 to form a heat and sound insulation layer; the heat and sound insulation material layer 3 is rock wool and rock wool board , glass wool, glass wool board, mineral wool, mineral wool board, polystyrene foam board, polyurethane foam board adopt one of mineral wool board or a combination of more than o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com