Fire-resistant lightweight particles and polyurethane filled wall panel and production method

A lightweight particle, polyurethane technology, applied in the direction of walls, fire prevention, building components, etc., can solve the problems of difficult to achieve the overall sealing of the wall and the combined splicing of the wall sealing, long maintenance time, increased weight, and inconvenient on-site construction. The effect of thermal insulation and sound insulation is good, saving man-hours and costs, and improving the strength of the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose of the invention, technical solutions and beneficial effects of the present invention clearer, the embodiments of the present invention will be described below in conjunction with the accompanying drawings. The features in can be combined arbitrarily with each other.

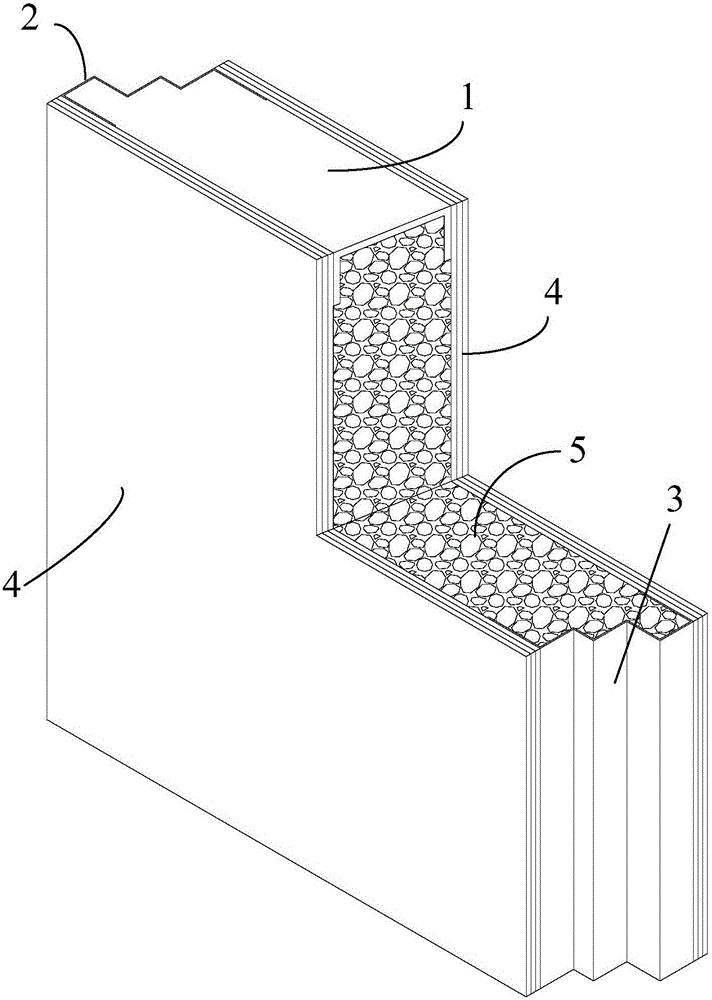

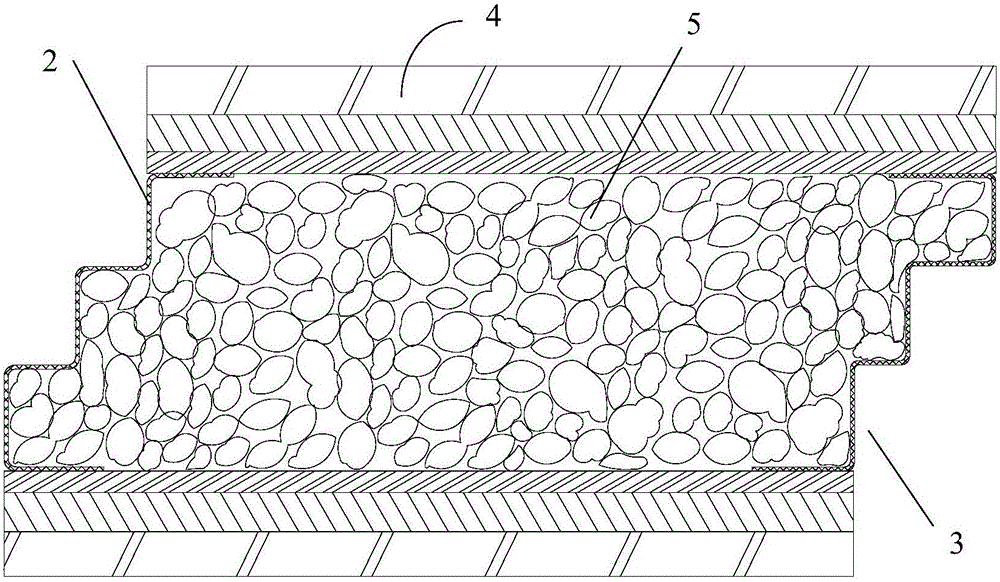

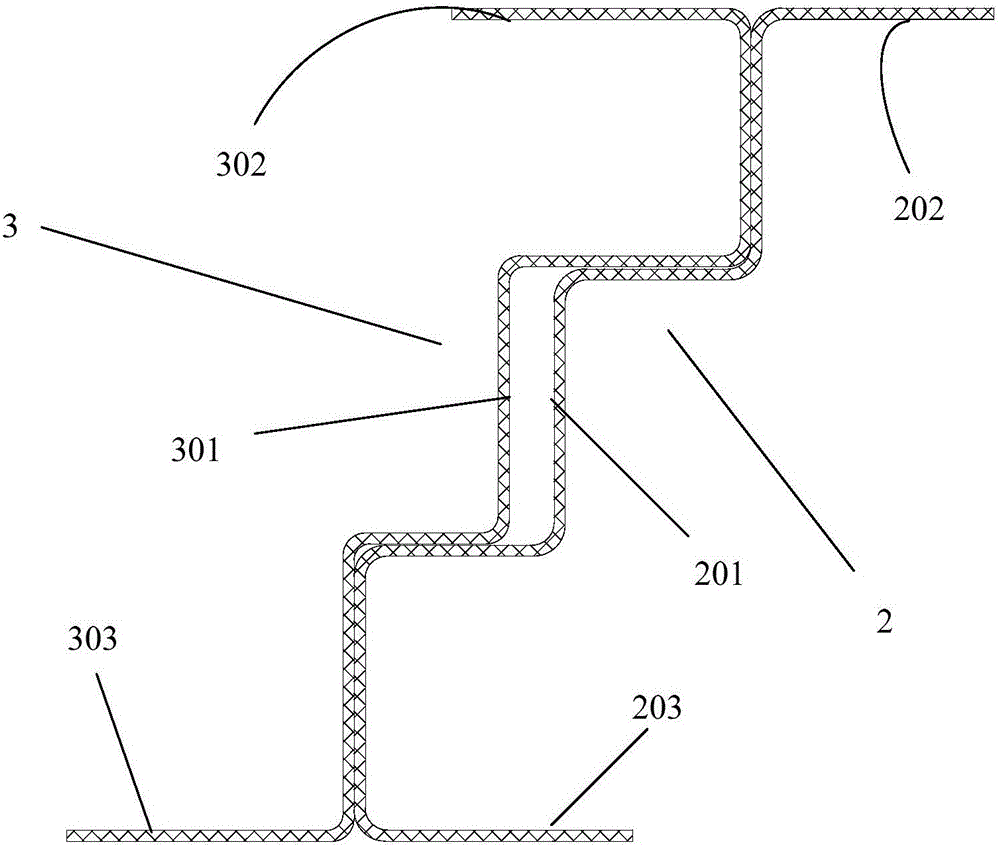

[0041] figure 1 and figure 2 It is a wall panel filled with refractory lightweight particles and polyurethane. Multiple wall panels are installed on the outside of the building wall and can be used for external wall insulation; multiple wall panels can be spliced together to form a whole wall to form a building partition. figure 1 3D schematic for filling wall panels with refractory lightweight granules and polyurethane foam such as figure 1As shown, the wallboard filled with refractory lightweight particles and polyurethane includes a support frame 1 , a first edge strip 2 , a second edge strip 3 , a wall panel 4 and an insulating material 5 . The support frame 1 is a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com