Light-weight high-strength foamed ceramic board material and preparation method thereof

A foamed ceramic and high-strength technology, which is applied in the field of lightweight and high-strength foamed ceramic plates and their preparation, can solve the problems of human and biological hazards, dust generation, air pollution, etc., so as to reduce pollution, reduce water consumption, and improve waterproof and moisture-proof. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A lightweight high-strength foamed ceramic plate, prepared from the following components in parts by weight: 50 parts of fly ash, 10 parts of bentonite, 10 parts of dolomite, 6 parts of potassium albite feldspar, 8 parts of magnesite slag, waste glass 5 parts, 1 part of anionic surfactant, 0.5 part of silicone resin polyether emulsion, 0.1 part of foaming agent, 0.1 part of dispersant, 200 parts of water.

Embodiment 2

[0024] A lightweight high-strength foamed ceramic plate, prepared from the following components in parts by weight: 60 parts of fly ash, 20 parts of bentonite, 20 parts of dolomite, 12 parts of potassium albite feldspar, 15 parts of magnesite slag, waste glass 10 parts, 2 parts of anionic surfactant, 1.5 parts of silicone resin polyether emulsion, 0.5 parts of foaming agent, 0.5 parts of dispersant, 250 parts of water.

Embodiment 3

[0026] A light-weight high-strength foamed ceramic plate, prepared from the following components in parts by weight: 55 parts of fly ash, 15 parts of bentonite, 15 parts of dolomite, 9 parts of potassium albite feldspar, 12 parts of magnesite slag, waste glass 8 parts, 1.5 parts of anionic surfactant, 1 part of silicone resin polyether emulsion, 0.3 parts of foaming agent, 0.3 parts of dispersant, 230 parts of water. Wherein, the mass content of potassium oxide and sodium oxide in potassium albite feldspar is greater than 11%, and the mass ratio of potassium oxide and sodium oxide is greater than 3, the anionic surfactant is sodium p-dodecyl sulfate, and the foaming agent is hydrogen peroxide. The dispersant is sodium lignosulfonate.

PUM

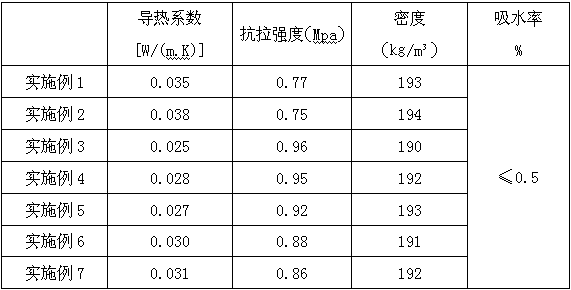

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com