Simplified non-polystyrene permanent insulating concrete form building system

a technology of non-polystyrene insulating concrete and building system, which is applied in the direction of walls, building components, building repairs, etc., can solve the problems of hygroscopic wood concrete wall system, little or nothing to interlock successive courses of wood wall, and the wall system “breathes” and other problems, to achieve the effect of enhancing the structural performance of the final wall structure, enhancing the strength and stability of the wall, and enhancing thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080]Use of the term ‘course’, in the present invention and as used in the building trade, is intended to mean a continuous and usually horizontal range of brick, shingles, non-polystyrene insulated concrete forms, or other materials as in a wall, roof, or other structure.

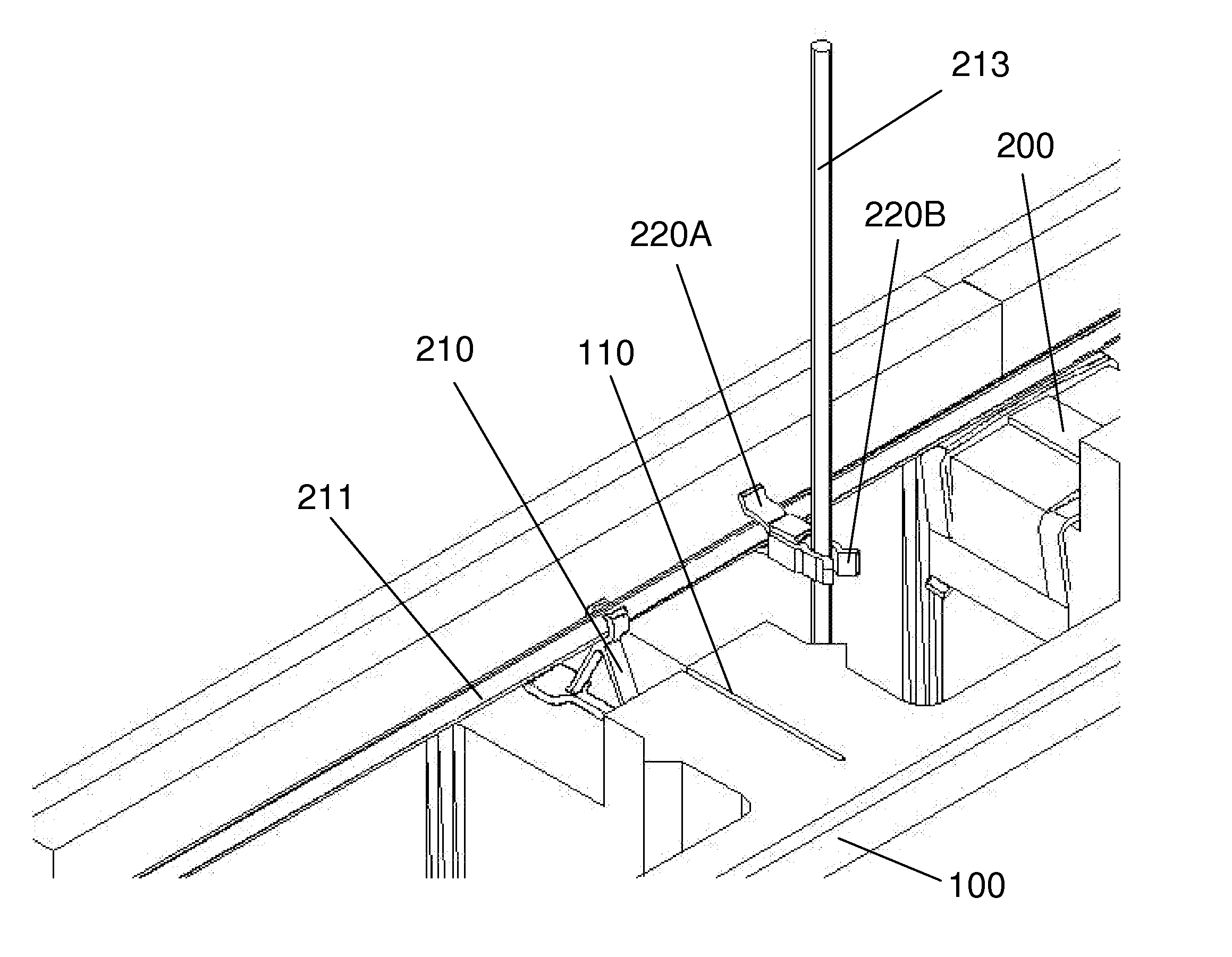

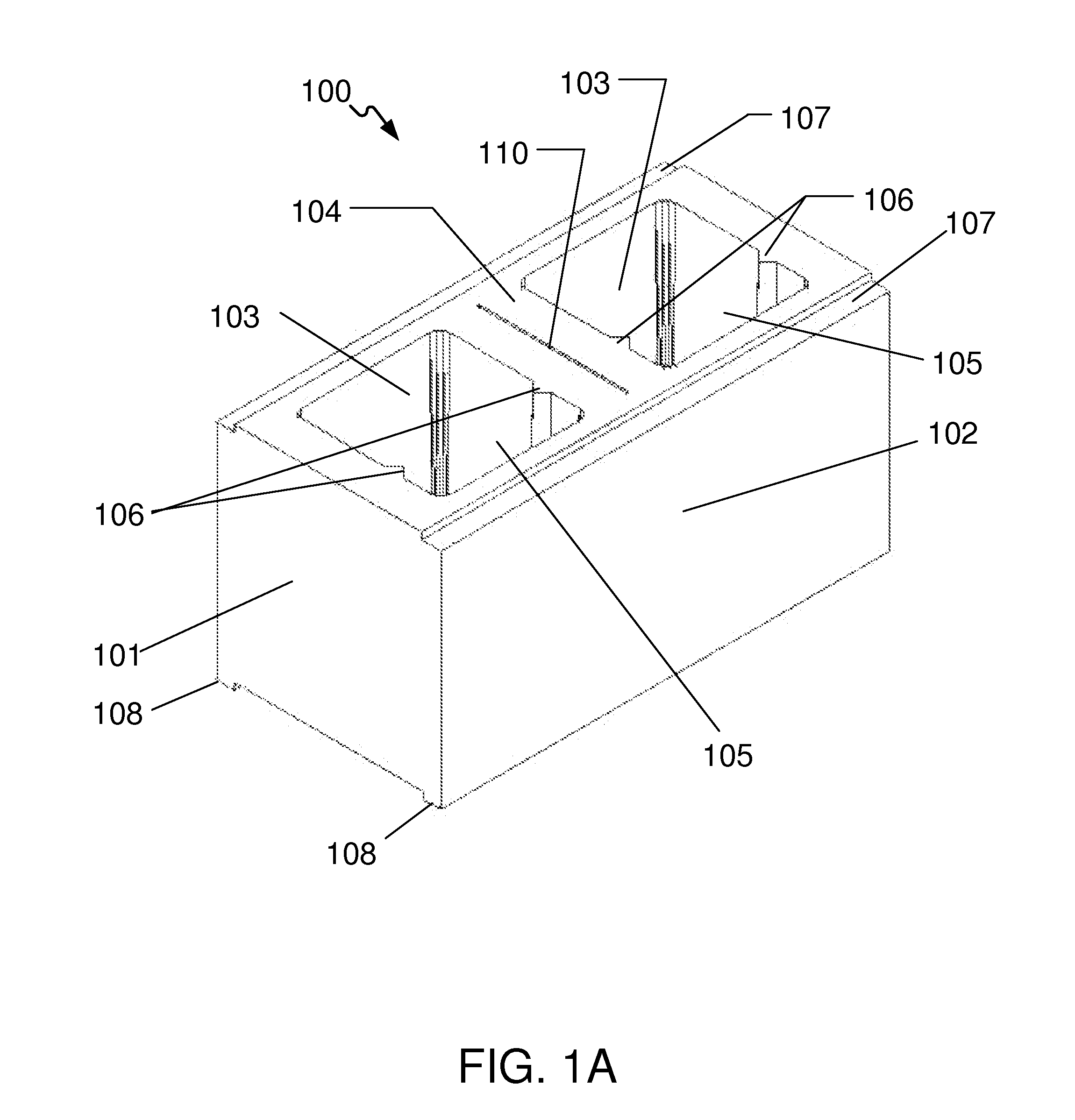

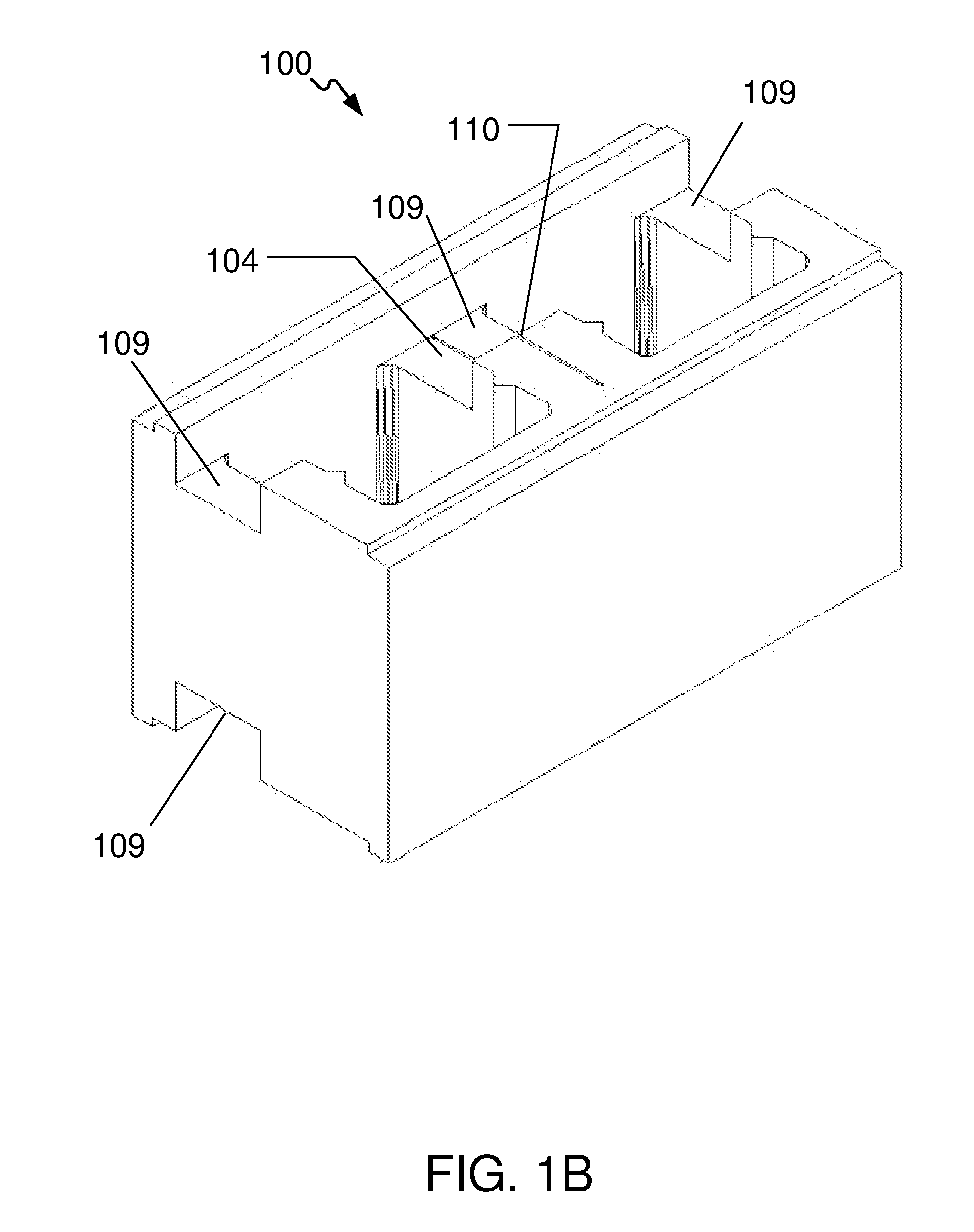

[0081]Turning now to the drawings in greater detail, it will be seen that in FIGS. 1A-1J there are illustrated examples of the non-polystyrene insulated concrete form which is part of the simplified non-polystyrene permanent insulating concrete form building system.

[0082]In an exemplary embodiment the simplified insulating concrete form building system is illustrated in FIGS. 1A to 1J. Referring to FIG. 1A there is illustrated one example of a non-polystyrene insulated concrete form 100 further comprising smooth non-articulated end faces 101, smooth non-articulated side walls 102, vertical cores 103, double middle web 104 with its middle web integral slot 110 which extends across the non-polystyrene insulated conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angles | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com