Complex self-adhesive elastic bandage and manufacturing method thereof

The technology of self-adhesive elastic bandage and composite adhesive is applied in the fields of medical bandaging and sports protection products, which can solve the problems of lack of elasticity, and achieve the effect of convenient bandaging and fixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

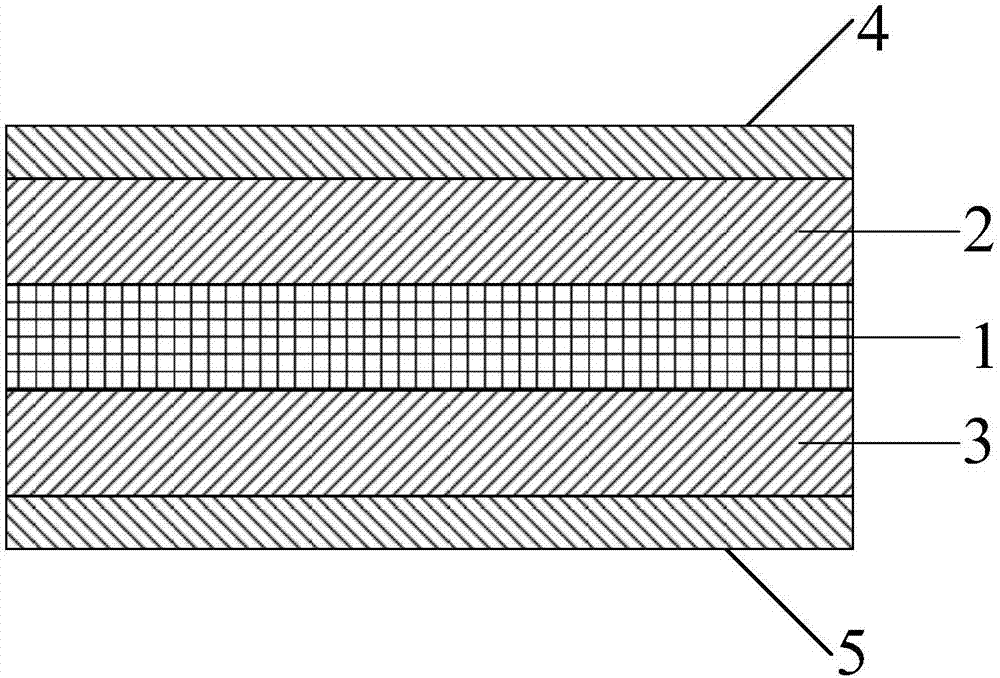

[0030] 1) Cloth compounding, select non-woven fabric as the upper and lower layers, spandex yarn as the middle layer, spandex yarn layer is sandwiched between the two non-woven fabric layers, and composite to form a bandage base material;

[0031] The non-woven fabric is polypropylene non-woven fabric. The fiber arrangement of polypropylene non-woven fabric is directional and longitudinally arranged. The longitudinal arrangement ratio of fibers is 85%. The fabric weight of polypropylene non-woven fabric is 12g / m 2 ;

[0032] The spandex yarn of the spandex yarn layer is the spandex yarn of 90D specification, and the warp direction density of the spandex yarn is 9 strands / inch, and the spandex yarn is the spandex yarn with 230% elongation in the stretched state;

[0033] 2) Prepare a composite adhesive, the composite adhesive is a composite adhesive of polyisoprene and polyacrylate, and the mass percentage of its components is: polyisoprene 70%, polyacrylate 30%;

[0034] 3) g...

Embodiment 2

[0038] 1) Cloth compounding, select non-woven fabric as the upper and lower layers, spandex yarn as the middle layer, spandex yarn layer is sandwiched between the two non-woven fabric layers, and composite to form a bandage base material;

[0039] The non-woven fabric is polypropylene non-woven fabric. The fiber arrangement of polypropylene non-woven fabric is directional and longitudinally arranged. The longitudinal arrangement ratio of fibers is 90%. The fabric weight of polypropylene non-woven fabric is 15g / m 2 ;

[0040] The spandex yarn of the spandex yarn layer is the spandex yarn of 120D specification, the warp density of the spandex yarn is 7 strands / inch, and the spandex yarn is the spandex yarn with 250% elongation in stretched state;

[0041] 2) Prepare a composite adhesive, the composite adhesive is a composite adhesive of polyisoprene and polyacrylate, and the mass percentage of its components is: polyisoprene 90%, polyacrylate 10%;

[0042] 3) gluing, coating co...

Embodiment 3

[0046] 1) Cloth compounding, select non-woven fabric as the upper and lower layers, spandex yarn as the middle layer, spandex yarn layer is sandwiched between the two non-woven fabric layers, and composite to form a bandage base material;

[0047] The non-woven fabric is polypropylene non-woven fabric. The fiber arrangement of polypropylene non-woven fabric is directional and longitudinally arranged. The longitudinal arrangement ratio of fibers is 70%. The fabric weight of polypropylene non-woven fabric is 8g / m 2 ;

[0048] The spandex yarn of the spandex yarn layer is the spandex yarn of 60D specification, and the warp direction density of the spandex yarn is 11 threads / inch, and the spandex yarn is the spandex yarn with 200% elongation in the stretched state;

[0049] 2) Prepare a composite adhesive, the composite adhesive is a composite adhesive of polyisoprene and polyacrylate, and the mass percentage of its components is: polyisoprene 60%, polyacrylate 40%;

[0050] 3) g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com