A scratch-resistant packaging structure for aluminum-plastic panel production

A packaging structure and aluminum-plastic panel technology, applied in the field of aluminum-plastic panel production, can solve the problems of no buffer device, low production efficiency, waste of manpower, etc., and achieve the effects of easy accumulation and placement, convenient fixed operation, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

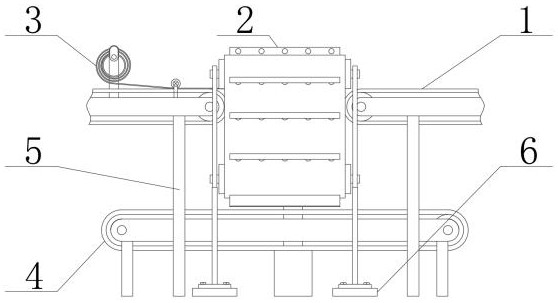

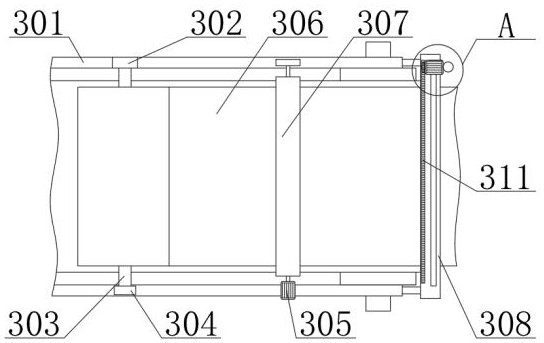

[0024] Example 1: see Figure 1-5 , the present invention provides a technical solution:

[0025] An anti-scratch packaging structure for the production of aluminum-plastic panels, including a material conveyor belt 1, a buffer device 2, a film releasing device 3, a conveying device 4, a supporting leg 5 and an adjustment device 6, and a buffer is provided on the left side of the material conveyor belt 1 Device 2, the left side of the buffer device 2 is provided with a film release device 3, the bottom of the buffer device 2 is provided with a placement plate 7, the bottom end of the placement plate 7 is provided with a support horizontal plate 8, and the bottom end of the support horizontal plate 8 is fixedly connected with a hydraulic pressure The telescopic rod 9, the outer sides of the material conveying belt 1, the buffer device 2, the film releasing device 3 and the conveying device 4 are all fixedly connected with supporting legs 5.

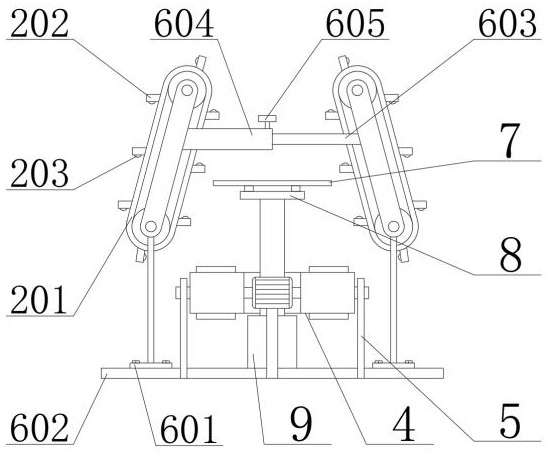

[0026] The buffer device 2 include...

Embodiment 2

[0028] Example 2: see Figure 1-5 , the present invention provides a technical solution:

[0029] When the device is in use, the external power supply is connected, and then the fixed plate 601 is slid on the sliding frame 602 according to the width of the aluminum-plastic plate after changing specifications, and then fixed by screws. At this time, the sleeve rod 603 will slide in the sleeve 604 , then turn the tightening screw 605 to fix it, then place the cut aluminum-plastic panel on the material conveyor belt 1, and then the material conveyor belt 1 pushes the aluminum-plastic panel, and then supports it through the support plate 202 on the buffer device 2 , the setting of the ball 203 can avoid direct contact between the aluminum-plastic plate and the support plate 202, and avoid friction, and then the first conveyor belt 201 rotates, and then drives the support plate 202 to move downward, so that the aluminum-plastic plate moves to the lower side of the placement plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com