Negative pressure anal drainage drug injector and manufacturing method thereof

A technology of negative pressure drainage and manufacturing method, applied in the medical field, can solve the problems such as the three-way valve can not meet the demand, the diversion or access to a plurality of different medicines, the difficulty, etc., to achieve the effect of good drainage effect, smooth pipeline and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

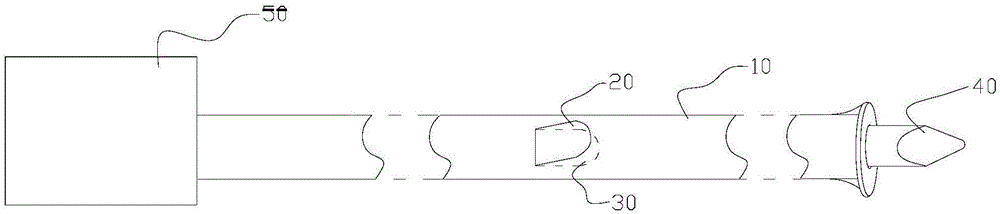

[0040] As shown in Figure 1, this embodiment provides an anal negative pressure drainage injector, which includes at least one pipeline product 10 for dredging liquid circulation, and the pipeline product 10 is provided with a small-diameter fluid drainage The pipe product 10 is provided with a plurality of covers 20 sequentially along the center line of the pipe, and a thin skin layer 30 is provided under the cover 20 to facilitate the insertion of branch drainage pipes. The port of the pipe product 10 is provided with an inclined puncture Point 40, one end of the pipeline product 10 is provided with a multi-way valve 50, and the multi-way valve 50 is also provided with a drug injector and a negative pressure bottle.

[0041] In this embodiment, the cover 20 is a transparent arc-shaped cover surface, the root of the cover 20 is connected to the outer surface of the pipeline product 10, the end of the cover 20 is an arc-shaped non-closed surface, and the The non-closed surface...

Embodiment 2

[0049] This embodiment provides a method for manufacturing an anal negative pressure drainage injector, comprising the following steps:

[0050] Step 1, according to polypropylene 50%, polyethylene wax 10%, polyurethane 10%, polyester thermoplastic elastomer 8%, nano silver powder 3%, methacrylate 1%, paraffin 0.5%, butyl acrylate 2%, Alkyl starch ester 3%, ammonium hydroxide 0.8%, sodium bicarbonate 0.2%, sodium lauryl sulfate 2%, titanium dioxide 3%, glycerin 3% weight ratio, mix and stir evenly;

[0051] Step 2, put the mixture of components into the reaction kettle, heat to 75°C under ammonia gas, and stir for 45 minutes;

[0052] Step 3: Send the reacted mixture into the extruder for extrusion. The extruder is divided into three temperature stages, the first temperature stage is 160°C, the second temperature stage is 210°C, and the third temperature stage is The stage is 240°C;

[0053] Step 4, control the pressure value at 5KPA, and gradually reduce the temperature to ...

Embodiment 3

[0057] This embodiment provides a method for manufacturing an anal negative pressure drainage injector, comprising the following steps:

[0058] Step 1, according to polypropylene 60%, polyethylene wax 8%, polyurethane 9%, polyester thermoplastic elastomer 7%, nano silver powder 2%, methacrylate 0.8%, paraffin 0.4%, butyl acrylate 1%, Alkyl starch ester 2%, ammonium hydroxide 0.5%, sodium bicarbonate 0.2%, sodium lauryl sulfate 1%, titanium dioxide 2%, glycerin 2% weight ratio, mix and stir evenly;

[0059] Step 2, put the mixture of components into the reaction kettle, heat to 80°C under ammonia gas, and stir for 50 minutes;

[0060] Step 3: Send the reacted mixture into the extruder for extrusion. The extruder is divided into three temperature stages, the first temperature stage is 180°C, the second temperature stage is 220°C, and the third temperature stage is The stage is 250°C;

[0061] Step 4, control the pressure value at 8KPA, and gradually reduce the temperature to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com