Automatic belt press

A belt press machine and automatic technology, which is applied to the parts and packaging of strapping machinery, can solve the problems of strapping falling off, inconvenient transportation, loose rolls, etc., and achieve the effect of not easy to loosen, not easy to fall off, tight and loose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings:

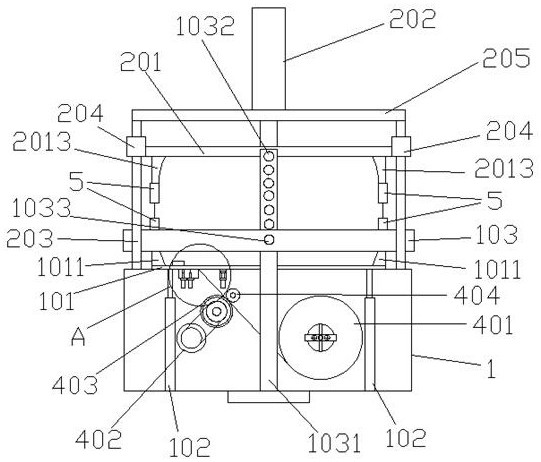

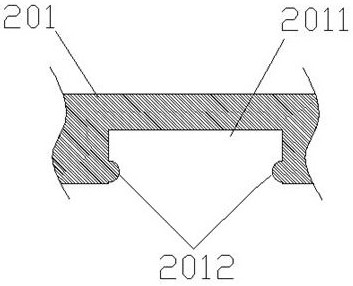

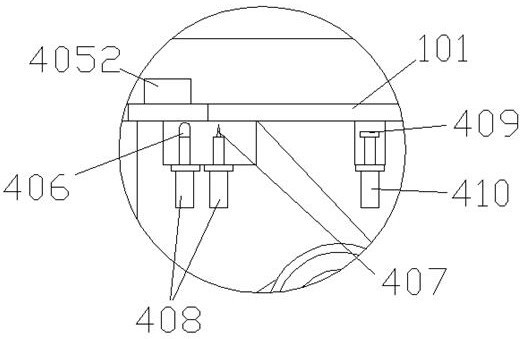

[0022] like Figure 1 to Figure 5 As shown, this embodiment provides an automatic belt pressing machine, which includes an operation table 1 and a belt pressing mechanism arranged above the operation table 1 . There are a plurality of guide columns 203, the pressure plate 201 is slidingly matched with the plurality of guide columns 203 through the sliding member 204, a fixing plate 205 is installed on the cylinder of the guide column 203 above the pressure plate 201, and the pressing cylinder 202 is fixedly installed in the The pressing plate 201 is mounted on the fixed plate 205 and driven to move along the guide column 203 . The automatic belt pressing machine of this embodiment can press the webbing roll, improve the tightness of the webbing roll, and facilitate bundling and transportation.

[0023] In this embodiment, the operating table 1 is provided with a stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com