Fiber reinforced epoxy resin/polyurethane laminated seismic insulation support and preparation method thereof

A fiber-reinforced, epoxy resin technology, applied in springs/shock absorbers, springs made of plastic materials, mechanical equipment, etc., can solve the difficulty in reflecting the value of steel plate/rubber laminated shock-isolation bearings, the number of layers and the height Limited problems, to avoid poor bonding, long lag time, and large load support capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

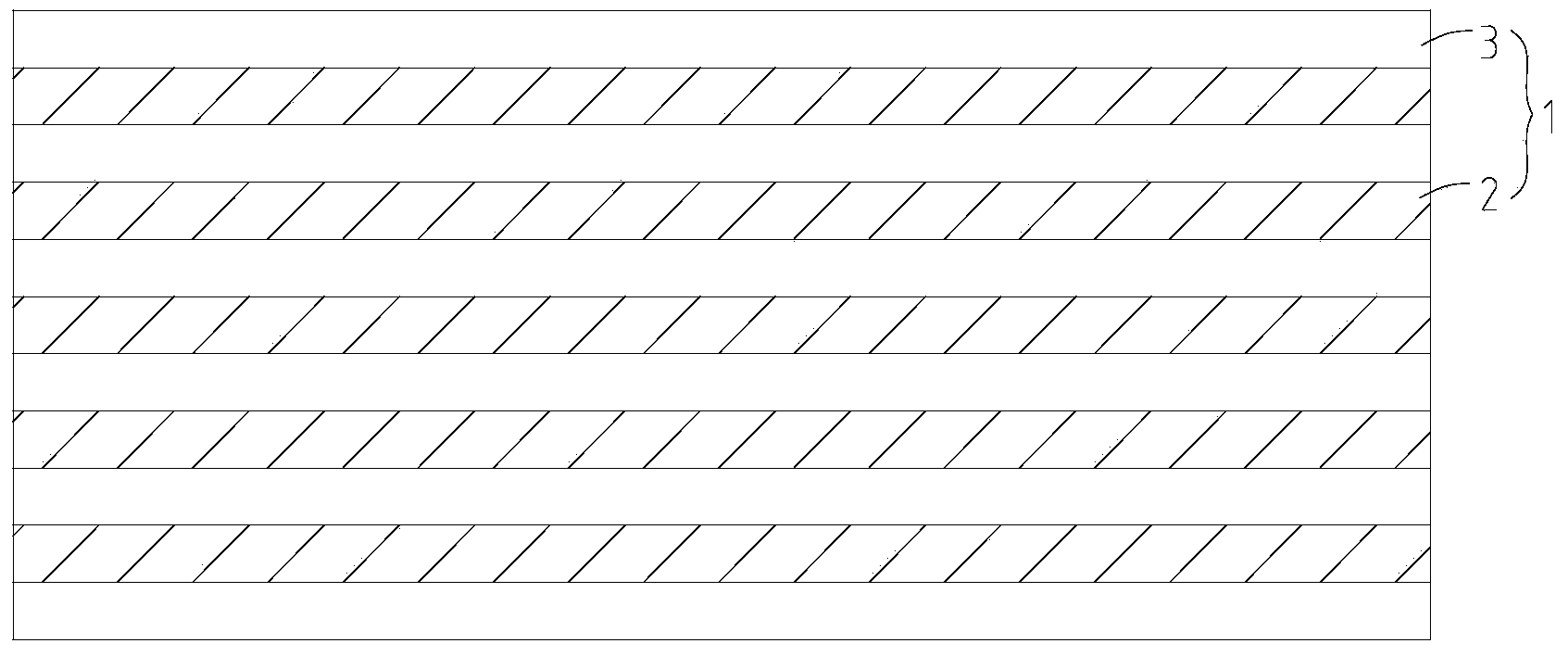

[0037] figure 1 Shown is one embodiment of the fiber-reinforced epoxy / polyurethane laminate seismic isolation bearing of the present invention.

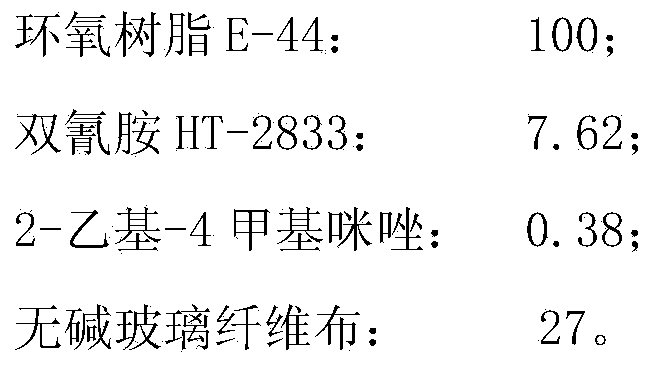

[0038] see figure 1 , the fiber-reinforced epoxy resin / polyurethane laminated seismic isolation bearing includes a bearing main body 1, the bearing main body 1 is formed by alternately superimposing and bonding fiber-reinforced epoxy resin boards 2 and polyurethane elastomer boards 3, and the Both outer layers of the main body of the support are polyurethane elastomer plates 3 . The thicknesses of the fiber-reinforced epoxy resin plate 2 and the polyurethane elastomer plate 3 are both 20mm. It should be understood that the thickness of the fiber-reinforced epoxy resin board and the polyurethane elastomer board can also be other values, su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com