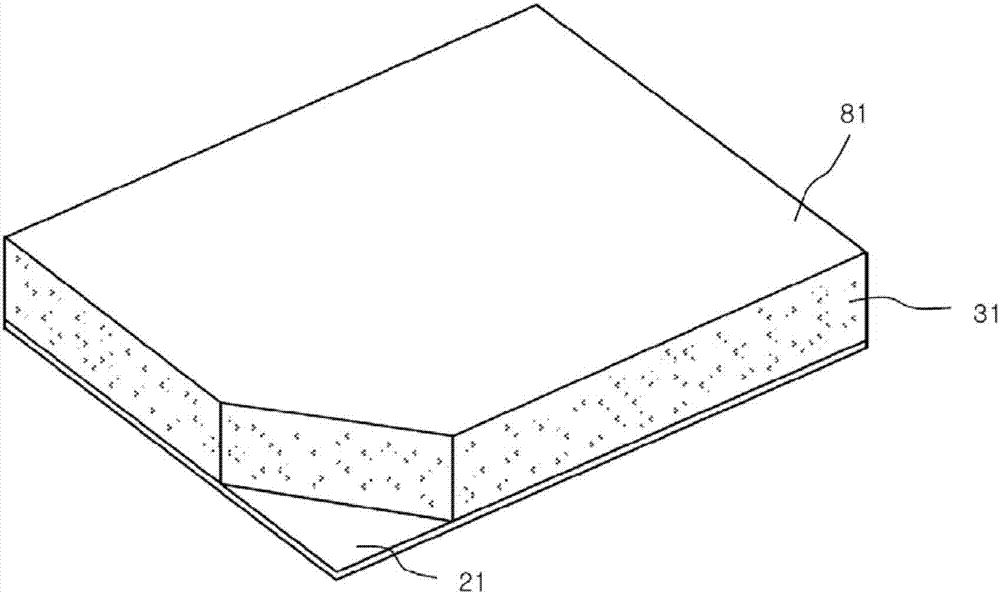

Thin film polyurethane foam laminate and method for manufacturing same

A technology of polyurethane foam and manufacturing method, applied in the directions of lamination, lamination device, chemical instrument and method, etc., can solve the problem of inability to effectively fill gaps in electronic equipment, inability to meet cushioning materials and sealing materials, and inability to perform cushioning materials and sealing materials. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

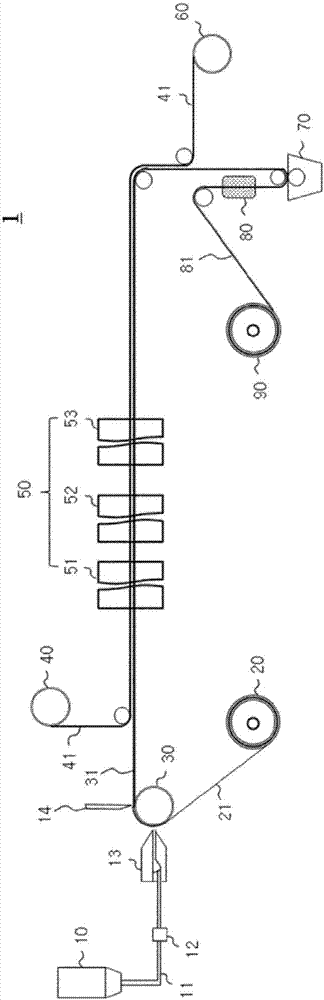

Method used

Image

Examples

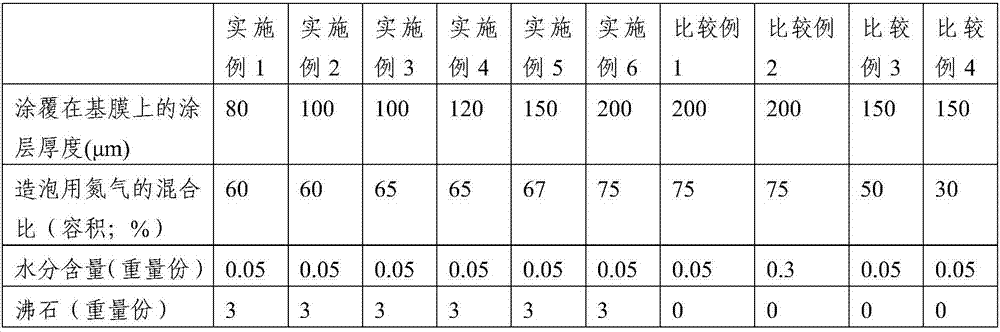

Embodiment 1

[0090] With regard to the foaming composition of the common condition, relative to 100 parts by weight of polyols, 0.05 parts by weight of residual moisture, 3 parts by weight of zeolite (molecular sieve powder), and hollow microspheres of 0.3 parts by weight are passed through the discharge device ( 13) The coating thickness of the applied gas-liquid mixture is 80 μm, the mixing ratio of foam-making nitrogen in the polyurethane raw material is 60%, and the second base film (41) is used as the artificial skin film to manufacture the polyurethane foam laminate .

Embodiment 2

[0092] A polyurethane foam laminate was produced under the same conditions as in Example 1, however, the coating thickness of the gas-liquid mixture applied by the discharger (13) was 100 μm.

Embodiment 3

[0094] A polyurethane foam laminate was produced under the same conditions as in Example 1, however, the coating thickness of the gas-liquid mixture applied by the discharger (13) was 100 μm, and the mixing ratio of nitrogen for foaming was 65%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com