Glass fiber-reinforced polyurethane sun roof and production method thereof

A production method, polyurethane technology, applied in the field of polyurethane products, can solve the problems of polyurethane product curvature and mold differences, and achieve the effects of saving medicine costs, saving labor, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

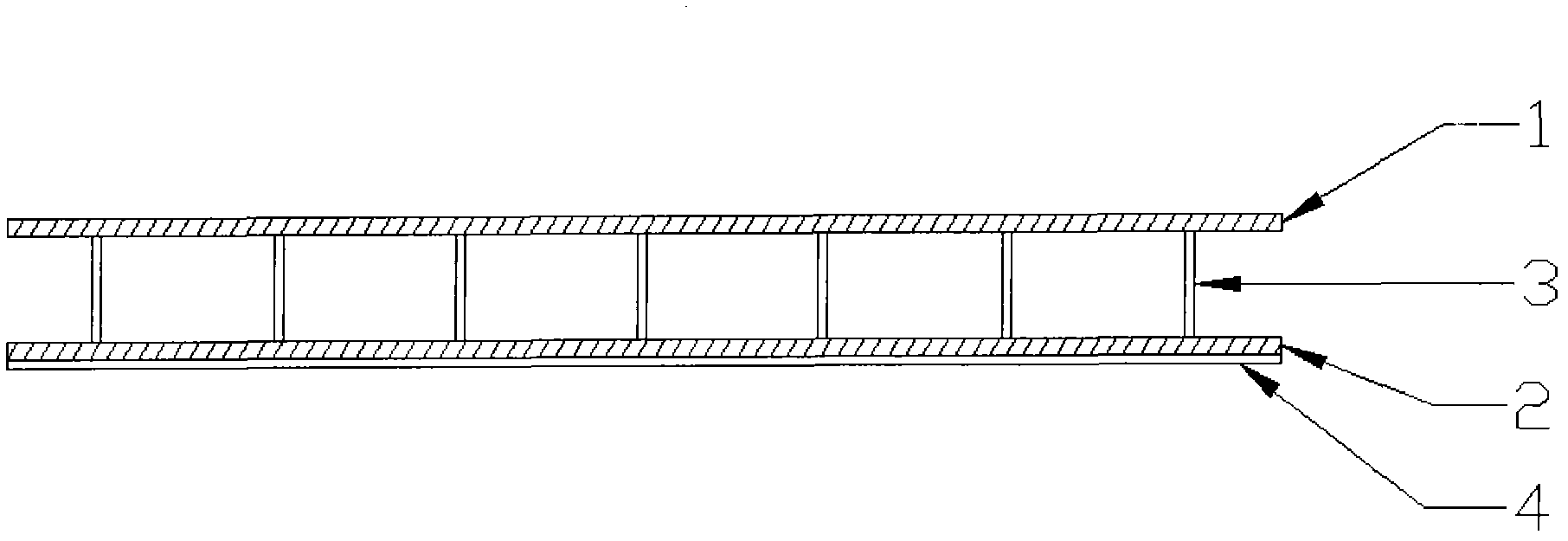

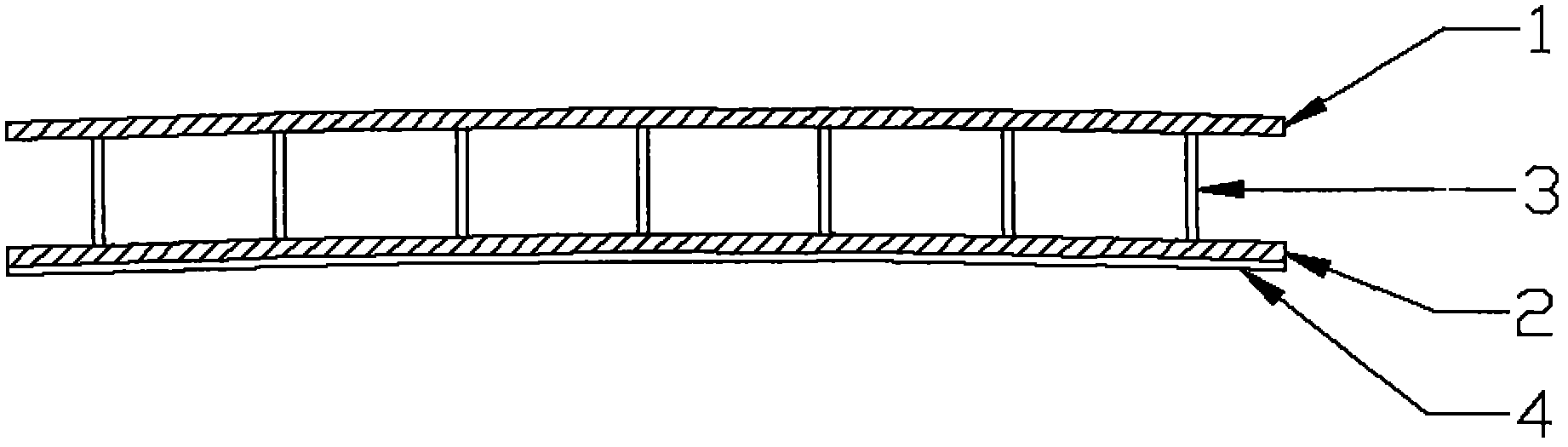

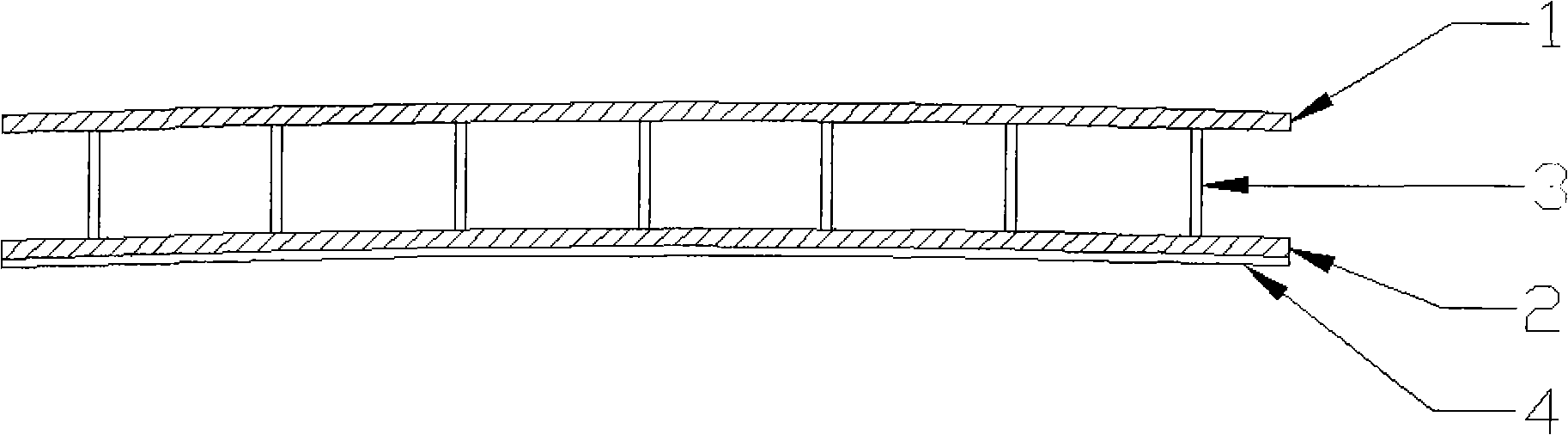

[0015] Example 1, see figure 1 , 2 , the same as the product in the comparative example, a glass fiber reinforced polyurethane sunshade, with a length of 700mm, a width of 400mm, and a thickness of 7mm. The product is cylindrical, and the radius of curvature in the length direction is 10,000mm; The non-woven fabric layer, glass fiber felt layer, honeycomb paper layer and glass fiber felt layer are laid neatly in order, and the two layers of glass fiber felt layer are 300g / m 2 , honeycomb paper layer thickness 7mm, non-woven fabric 60g / m 2 PET, the front and back of the material are sprayed with polyurethane material, and the spraying density of polyurethane material on both surfaces is 400g / m 2 , feed the material sprayed with polyurethane material into the mold, with the concave surface of the mold facing up, keep the non-woven fabric layer on the glass fiber and put it into the mold, the mold temperature is 120°C, and the pressure is kept for 2 minutes to make polyurethane...

Embodiment 2

[0017] Example 2, see figure 1 , 2 , the same as Example 1, the difference is that the material is laid neatly in the order of glass fiber mat layer, honeycomb paper layer, glass fiber mat layer and non-woven fabric layer from bottom to top, and the non-woven fabric layer is 100g / m 2 PP, after spraying polyurethane material on the surface of the material, keep the non-woven fabric layer on top of the glass fiber felt layer and put it into the mold, the mold temperature is 120°C, hold the pressure for 2 minutes, and take out the product; They are an upper glass fiber reinforced polyurethane layer 1 and a lower glass fiber reinforced polyurethane layer 2, and the upper glass fiber reinforced polyurethane layer 1 is a non-woven fabric reinforced polyurethane layer 4.

[0018] According to the measurement method in the comparative example, the product produced in Example 1 was measured, and the maximum value of the arc was 8.6mm, the minimum value was 4.9mm, and the average val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com