A kind of preparation method of electric brush plating using electric brush plating device

A technology of brush plating and clamping, applied in the direction of electrolytic components, electrolytic process, etc., can solve the problems of endangering the health, waste of electroplating solution, and high labor intensity of manual operation, so as to reduce labor intensity and ensure the quality of the plating layer. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

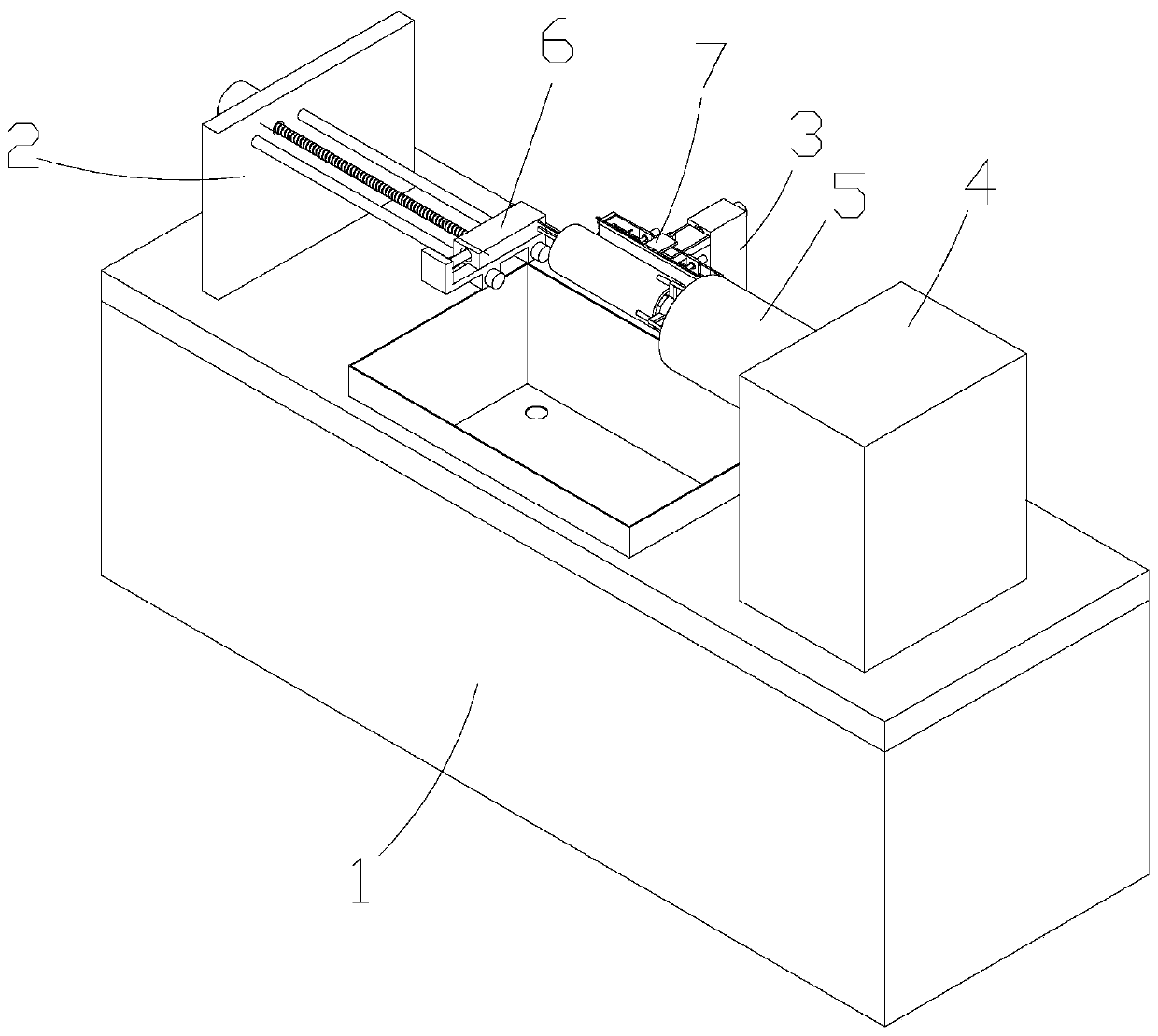

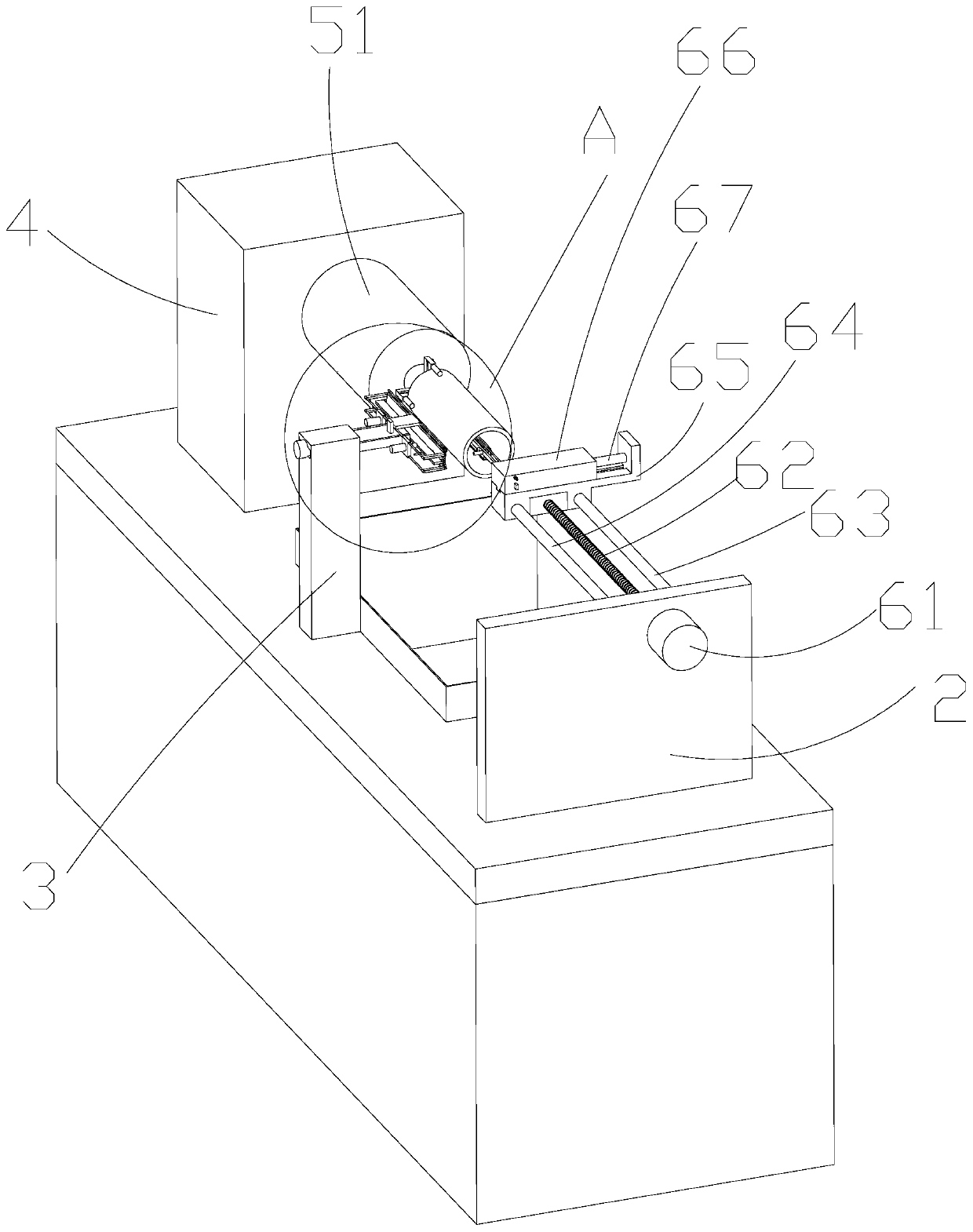

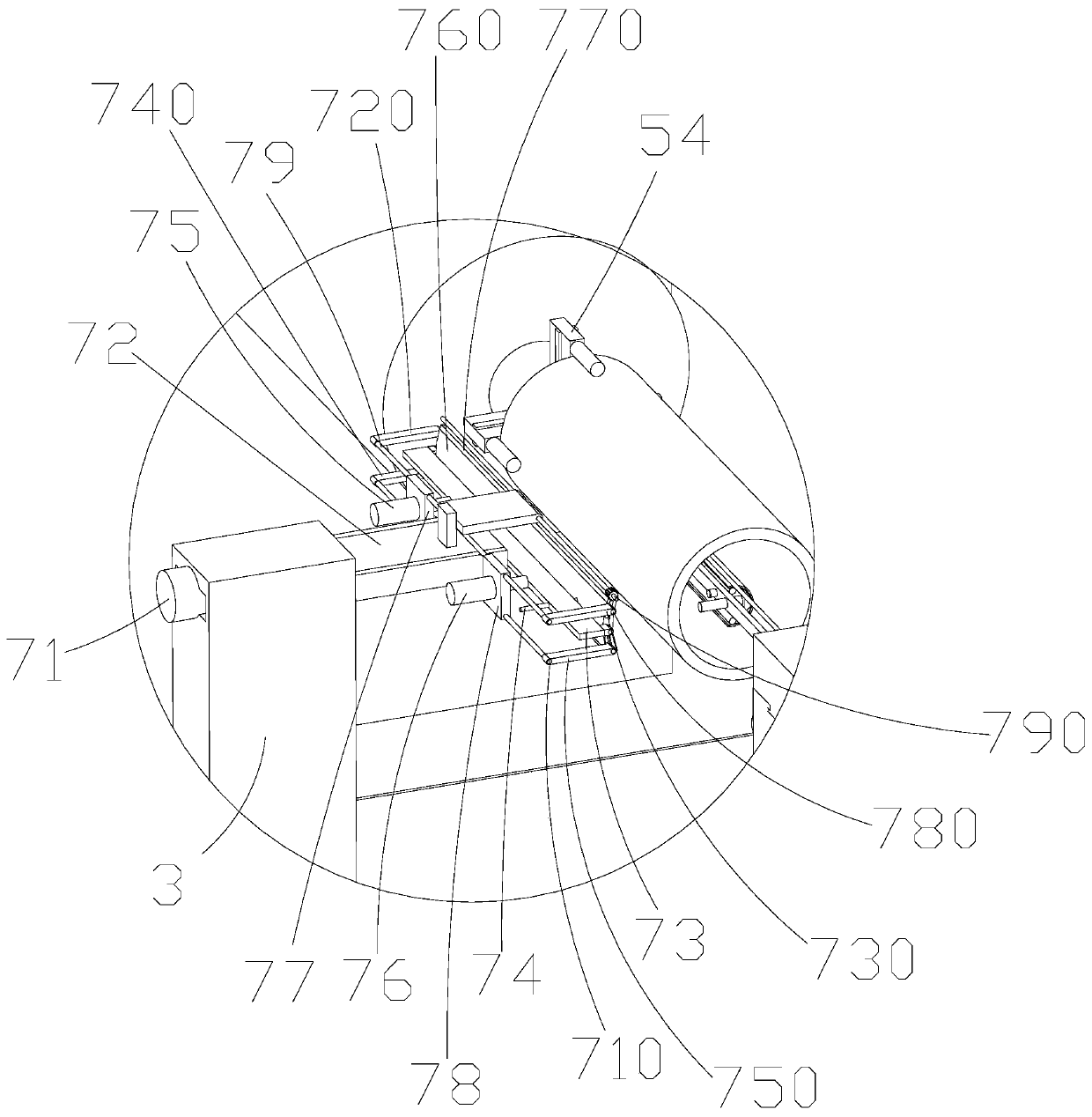

[0025] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

[0026] A preparation method for brush plating using a brush plating device, comprising the following steps:

[0027] a. Pre-plating pretreatment: treat the surface of the workpiece to be processed, and the oil stains, rust spots, burrs, tapers, out-of-roundness and fatigue layers on the surface, so as to obtain qualified surface roughness of the workpiece and expose the normal structure of the base metal;

[0028] b. Clamping and fixing: place the workpiece to be processed on the clamping assembly, fix the workpiece to be processed through the clamping assembly, and the rotation center of the clamping assembly and the center of the workpiece to be processed are on the same axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com