Polyurethane composite plate

A technology of composite board and polyurethane board, which is applied in the direction of synthetic resin layered products, transportation and packaging, chemical instruments and methods, etc., can solve the problems of high cost, strong pungent smell, irritating human skin, etc., and achieve product quality Light, no dust pollution, good heat and sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The determination of thermal conductivity refers to GB / T 1C295-2008 "Determination of Stable Thermal Resistance and Related Properties of Thermal Insulation Materials - Heat Flow Meter

[0018] Law".

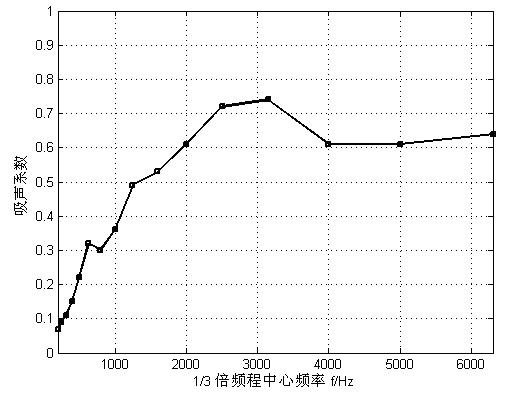

[0019] The sound absorption coefficient is measured with reference to ISO10534-2 (corresponding national standard GB / T18696.2-2002), and is measured by transfer function method.

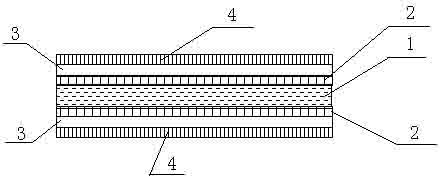

[0020] Such as figure 1 As shown, a polyurethane composite board is composed of polyurethane board, phenolic resin, hot melt adhesive film and non-woven fabric

[0021] Combination, that is, the composition of the composite board from top to bottom is non-woven fabric, hot-melt adhesive film, phenolic resin, polyurethane board, phenolic resin, hot-melt adhesive film, and non-woven fabric. The parts by mass of each layer are: 26 parts of non-woven fabric, 10 parts of hot melt adhesive film, 8 parts of phenolic resin, and 56 parts of polyurethane board. The density of polyurethane board is 17kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com