Polyurethane laminated moulding product and preparation method thereof

A polyurethane layer, polyurethane resin technology, applied in the direction of layered products, metal layered products, chemical instruments and methods, etc., can solve problems such as increased cost, production suspension, poor demoulding effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] II. Process for the preparation of polyurethane laminate molding compositions

[0062] The present invention also provides a kind of preparation method of polyurethane lamination molding composition on the other hand, described preparation method comprises steps:

[0063] i) providing a part to be laminated, said part to be laminated comprising a core layer and one or more layers of reinforcing fiber mat or reinforcing fiber fabric disposed on at least one side of said core layer;

[0064] ii) applying the above polyurethane resin composition on the reinforcing fiber mat or reinforcing fiber fabric layer;

[0065] iii) placing the part obtained in step ii) in a mold, laminating the part to obtain a three-dimensional shape, and curing the polyurethane resin composition; and

[0066] iv) demoulding to obtain said polyurethane laminate molding,

[0067] The method provided by the invention can reduce the frequency of use of the external release agent, improve productio...

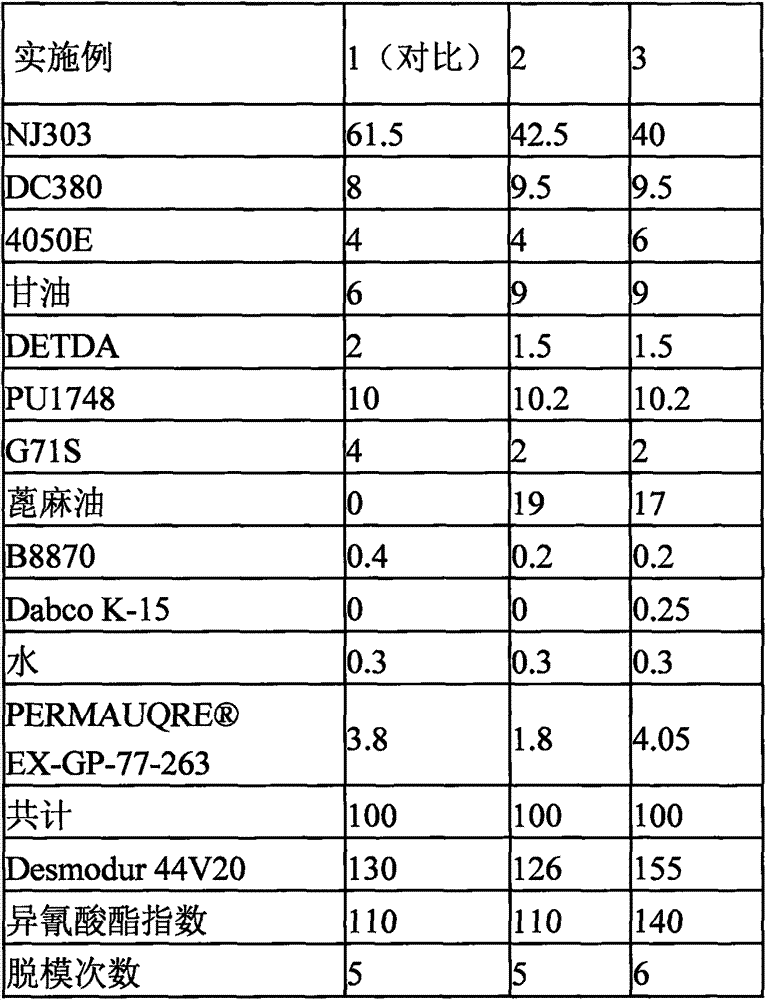

Embodiment 1-3

[0081] Mix the components in each example in Table 1 except isocyanate, mix with isocyanate through a high-pressure spraying system and spray on the "interlayer semi-finished product". The so-called interlayer semi-finished product is a honeycomb cardboard covered with glass fiber felt on both sides. The weight of glass fiber mat used is 250g / m 2 , the spraying amount of the polyurethane resin composition is 250g / m 2 . After spraying, the mechanical arm sends the sprayed object to the press, and solidifies it at a mold temperature of 120°C. The number of self-releases is tested on a mold coated with the same external release dose. Polyurethane laminated molded articles were obtained, and the demoulding time was 90 seconds in each case.

[0082] In order to accurately measure the demoulding effect, the same amount of external mold release agent is sprayed on the mold each time, and a puller is used for demoulding when demoulding. If the pulling force displayed on the puller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com