Polyurethane composite film

A composite film, polyurethane technology, applied in synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of short life, easy wear, poor surface strength of PTFE film, etc. The effect of surface strength, improving quality and grade, and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

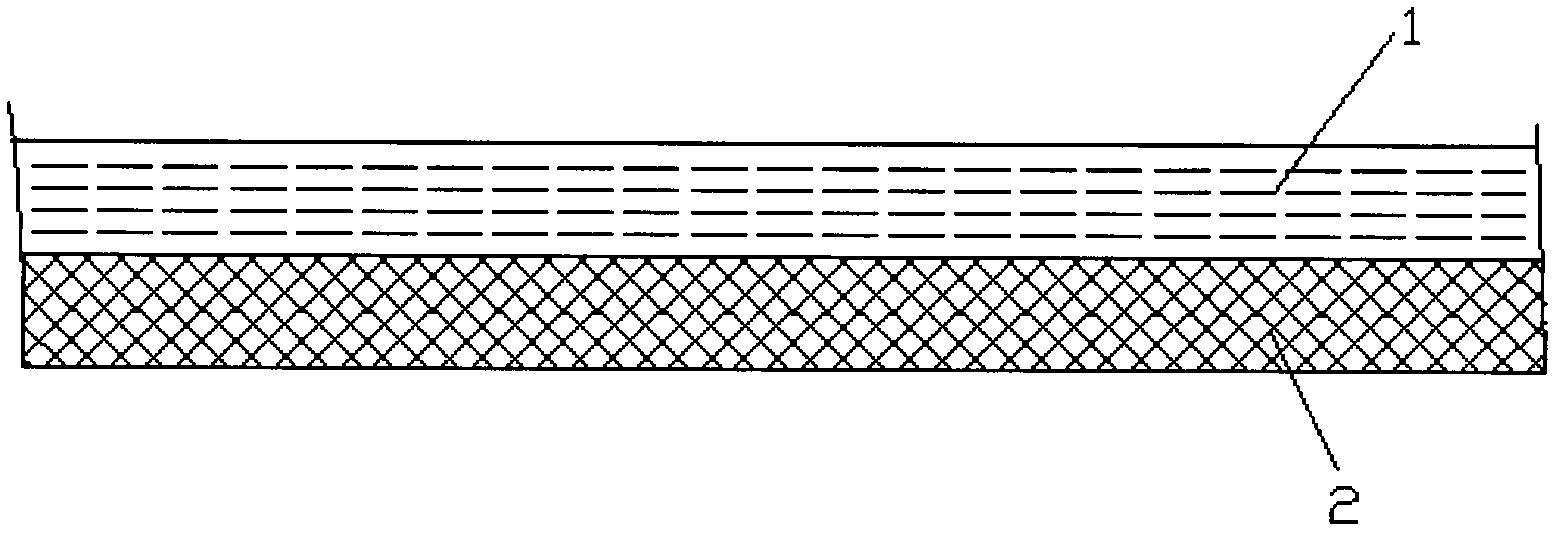

[0017] A polyurethane composite film, such as figure 1 , including a polyurethane layer 1 and a polytetrafluoroethylene layer 2, the polyurethane layer has two opposite sides, and the polytetrafluoroethylene layer is compounded on one side of the polyurethane layer.

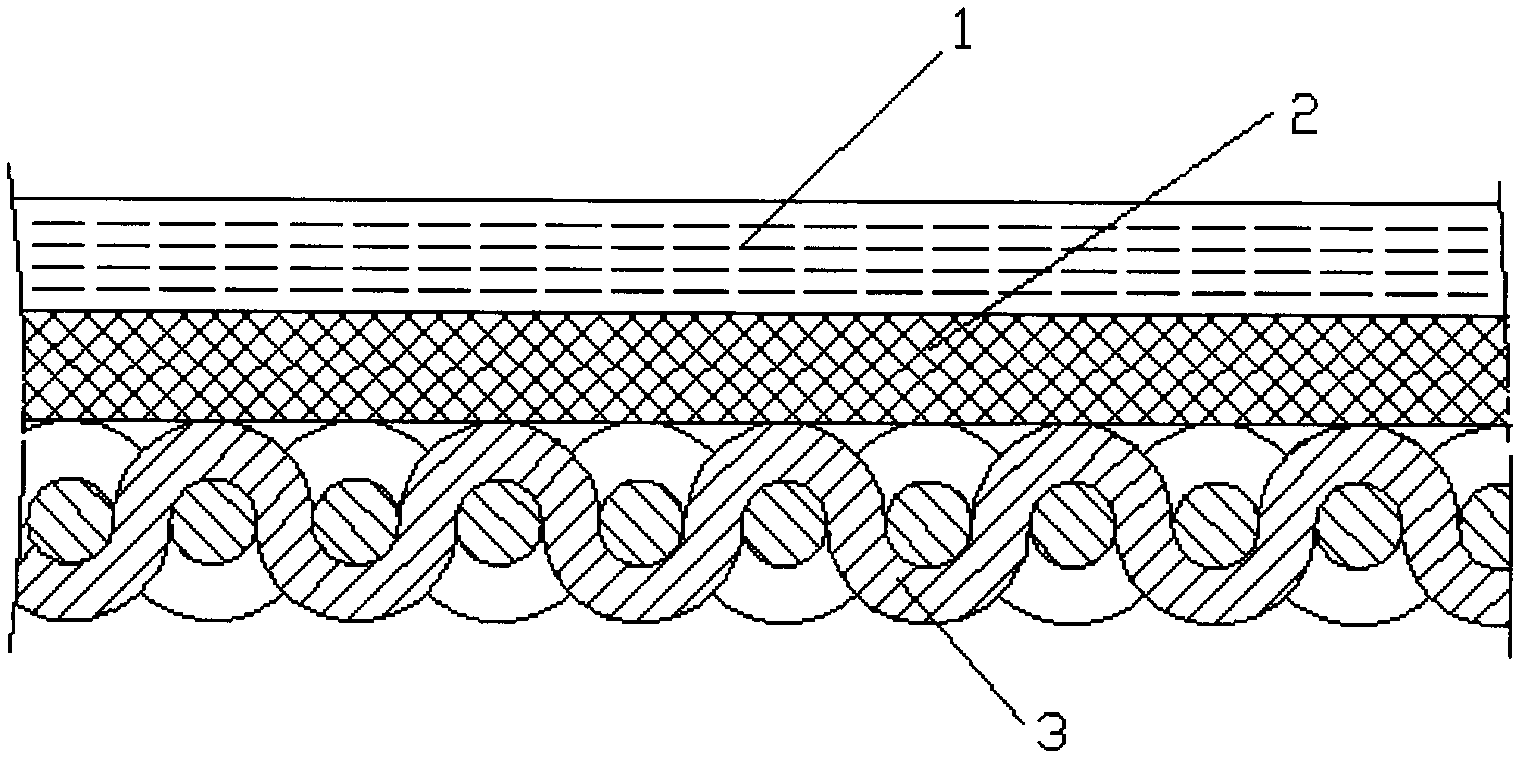

[0018] Such as figure 2 As shown, a textile layer 3 is also compounded on the other side of the polyurethane layer.

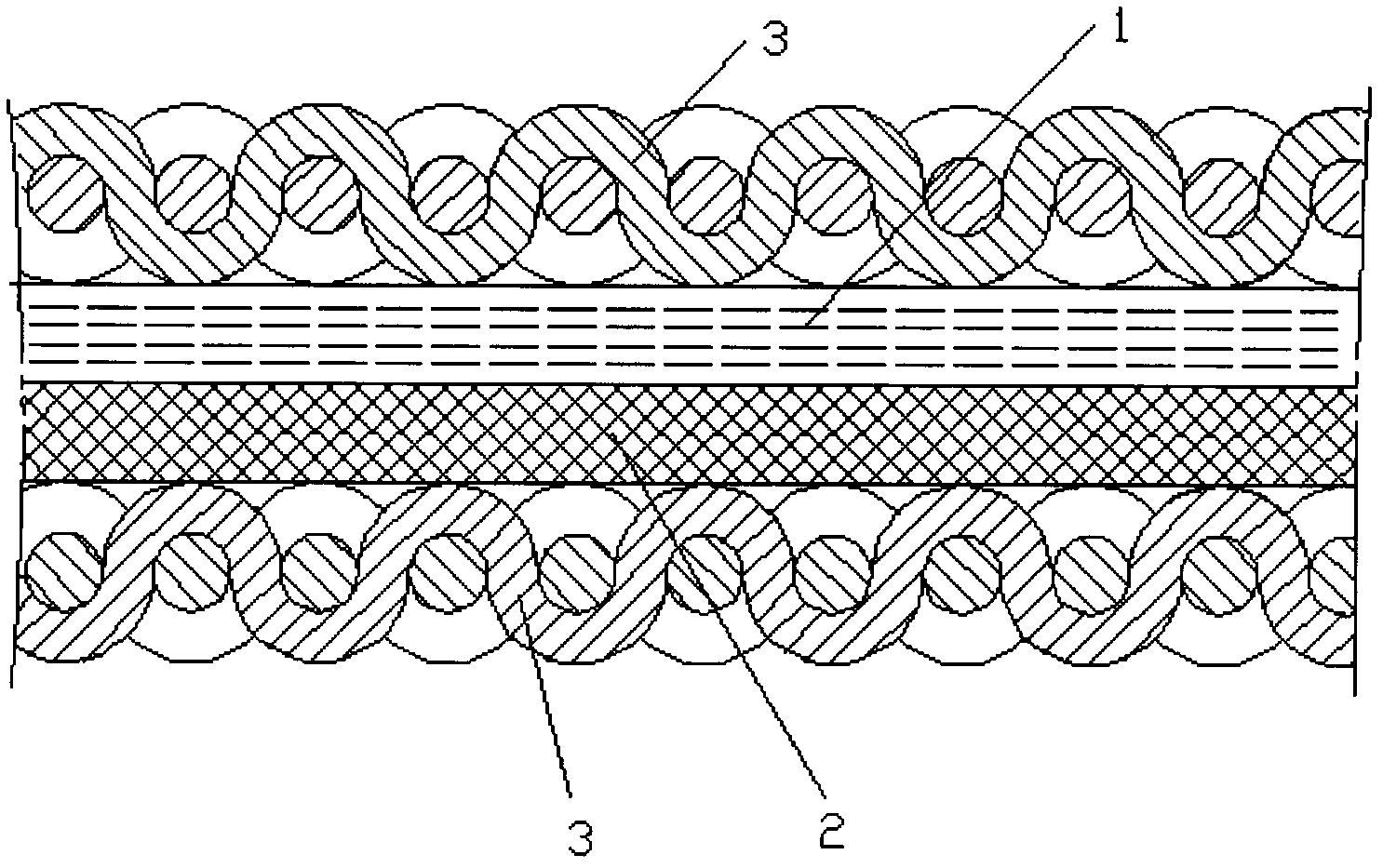

[0019] Such as image 3 As shown, a textile layer is compounded on the surface of the polytetrafluoroethylene layer away from the polyurethane layer.

[0020] The above-mentioned polyurethane layer is a hydrophilic swelling type polyurethane layer.

[0021] The above-mentioned polyurethane layer may also be a moisture-permeable non-swellable microporous air-permeable polyurethane layer.

[0022] The above-mentioned polyurethane layer can also be a waterproof, moisture-permeable, hydrophilic and non-swellable polyurethane layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com