A steel plate/polyurethane laminated shock-isolation bearing and its manufacturing method

A seismic isolation bearing and polyurethane technology, which is applied in the direction of earthquake resistance, bridges, bridge parts, etc., can solve the problems of difficulty in setting the vulcanization conditions of laminated rubber, lack of seismic isolation effect, and high production process requirements, so as to avoid bonding Bad, high elasticity, good impact resistance and vibration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below with reference to the accompanying drawings and embodiments.

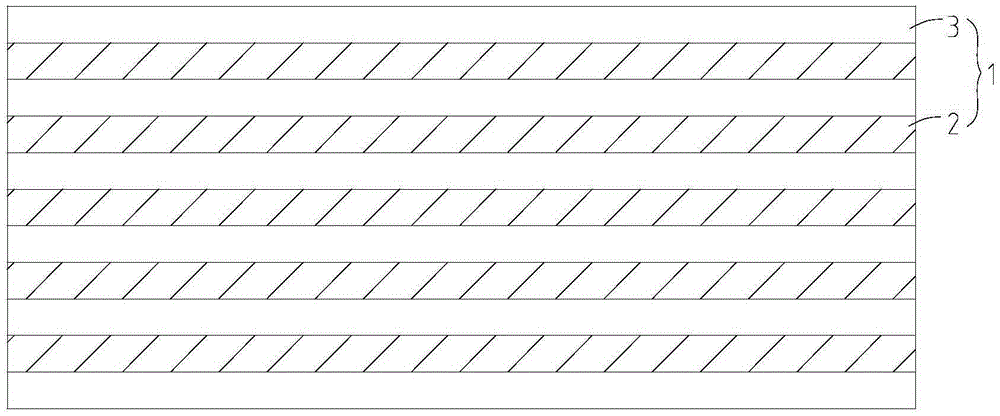

[0027] figure 1 Shown is one embodiment of the steel plate / polyurethane laminated seismic isolation support of the present invention.

[0028] See figure 1 The steel plate / polyurethane laminated seismic isolation support includes a support main body 1 which is formed by alternately superposing and bonding steel plates 2 and polyurethane elastomer plates 3, and the two outer layers of the support main body are both Polyurethane elastomer board 3. The thickness of the steel plate 2 and the polyurethane elastomer plate 3 are both 20 mm. It should be understood that the thickness of the steel plate and polyurethane elastomer plate may also have other values, such as other values in 2-20 mm.

[0029] The following are several manufacturing methods for the above-mentioned steel plate / polyureth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com