Photochromic contact lenses and methods for their production

a technology of contact lenses and compositions, applied in the field of photochromic tinting compositions, can solve the problems of not producing commercially desirable contact lenses, existing photochromic compounds, and methods for producing very thin photochromic articles, such as contact lenses, and providing enough darkening to produce a noticeable difference to the wearer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0068] Binding polymer was formed by the following process:

[0069] To the cold stirred reactor was added about 537 g 1-octanethiol, followed by 20,850 g 2-hydroxyethylmethacrylate, 283 g methacrylic acid, 29,415 g isopropyl lactate, 7,363 g 1-ethoxy-2-propanol, and 973 g glycerol. The reactor was heated to about 68° C., and 128 g parts 2,2′-azobis-(2-methylbutyronitrile) was added to start the polymerization process. After 3 hours most of the monomers had reacted, but the temperature was maintained overnight at 68° C. to finish the process. The reactor was heated to about 80° C. for about 24 hours more to destroy excess initiator. The reactor was cooled and the viscosity was adjusted to 5900 to 7700 mPas (23° C.) by adding about 1,000 g of a mixture of the above-mentioned solvents. The solution was filtered through a 5 micron filter to obtain the finished binding polymer having a Mpeak of about 28,000 g / mole.

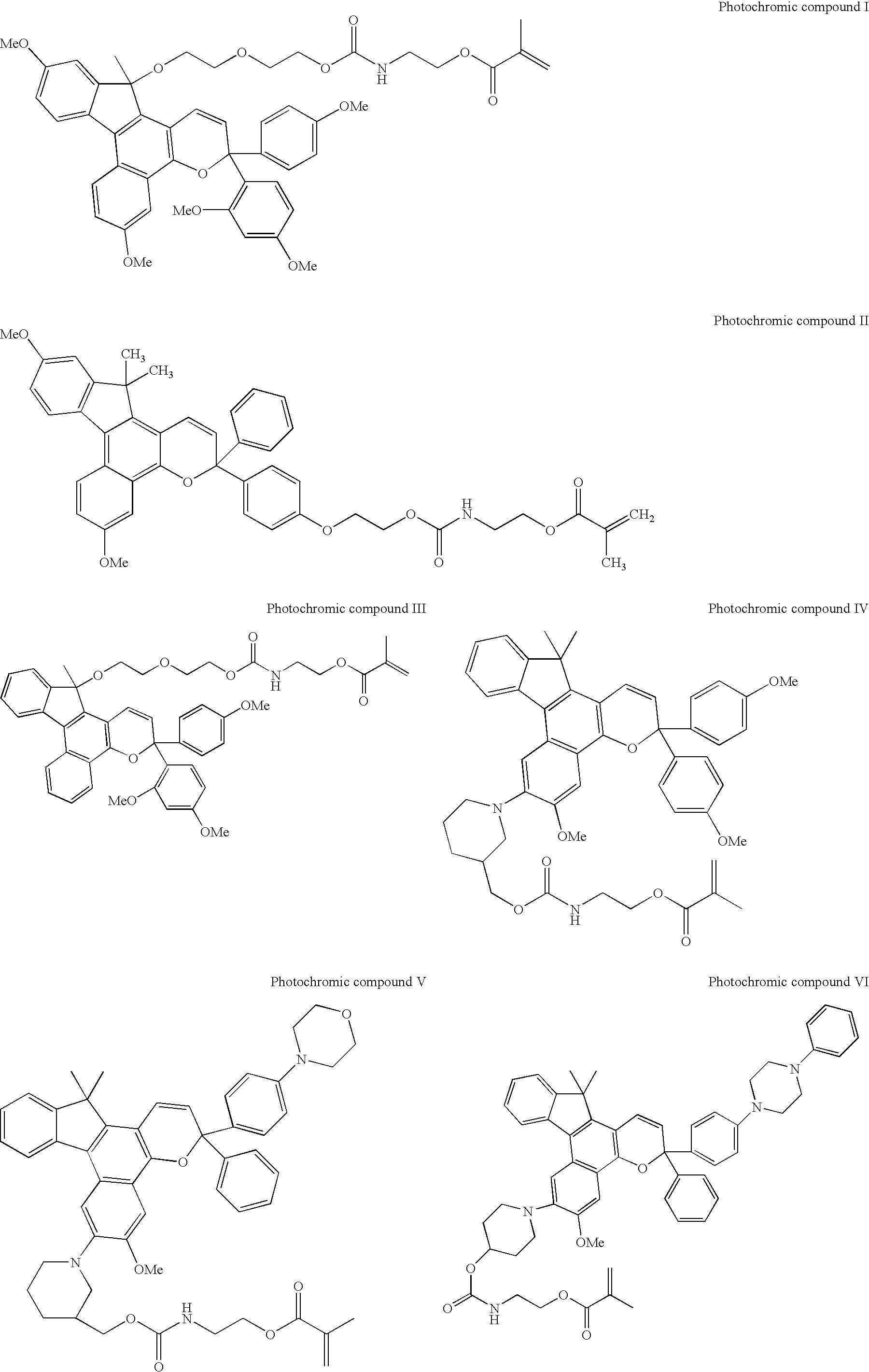

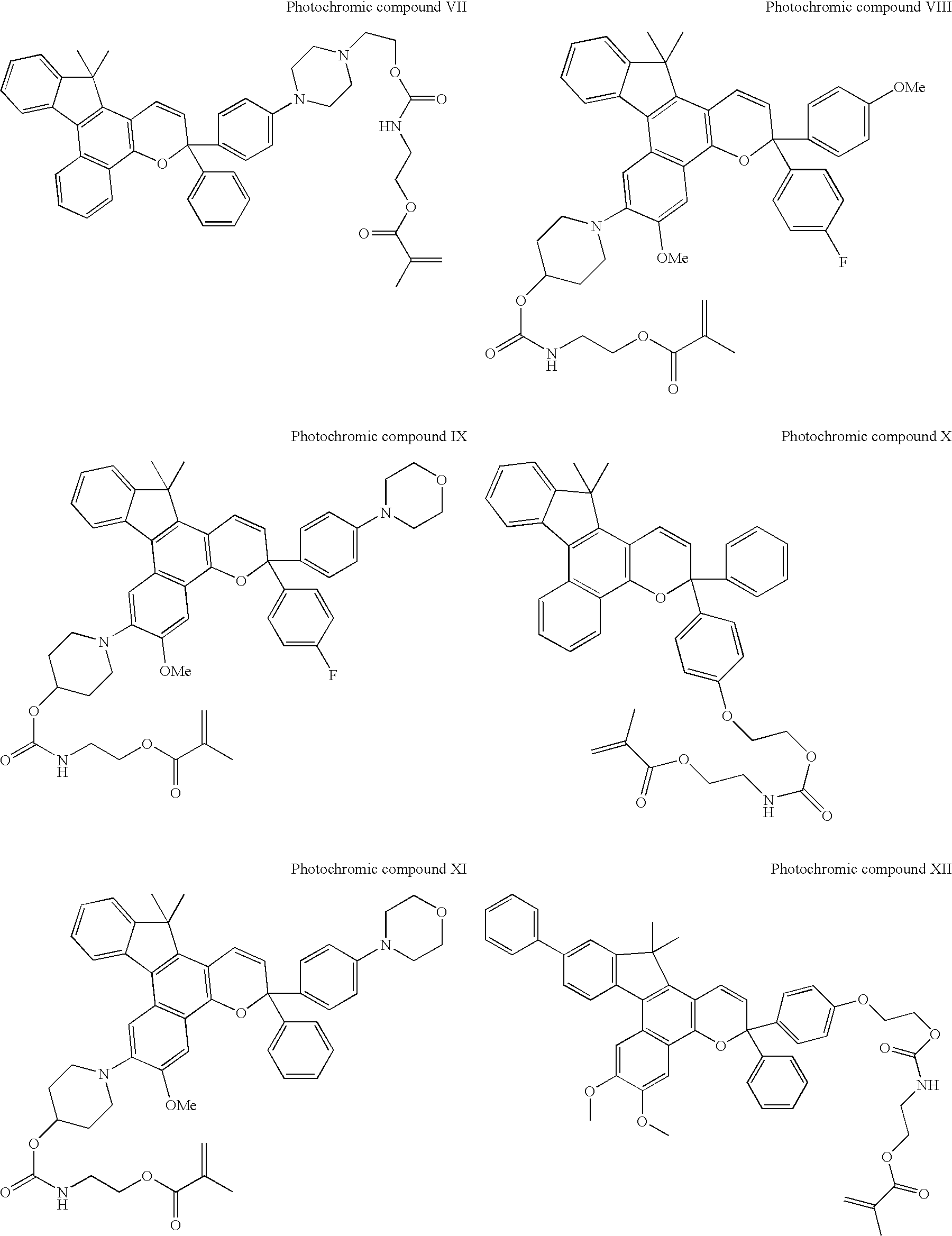

[0070] Photochromic colorant, a dark green, slightly viscous solution cont...

example 2

[0075] The procedure of Example 1 was repeated except using photochromic dye II.

example 3

[0076] The procedure of Example 2 was repeated except using 9% (wt) photochromic dye II, and omitting the MEHQ in the coating mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com