Photochromic lens and preparation method and application thereof

A color-changing lens and photochromic technology, which is applied in the field of spectacle lenses, can solve problems such as the inability to meet the needs of the depth of color change, the inability to see objects, and the user's dizziness, so as to protect from strong light damage, avoid dizziness or instantaneous invisibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

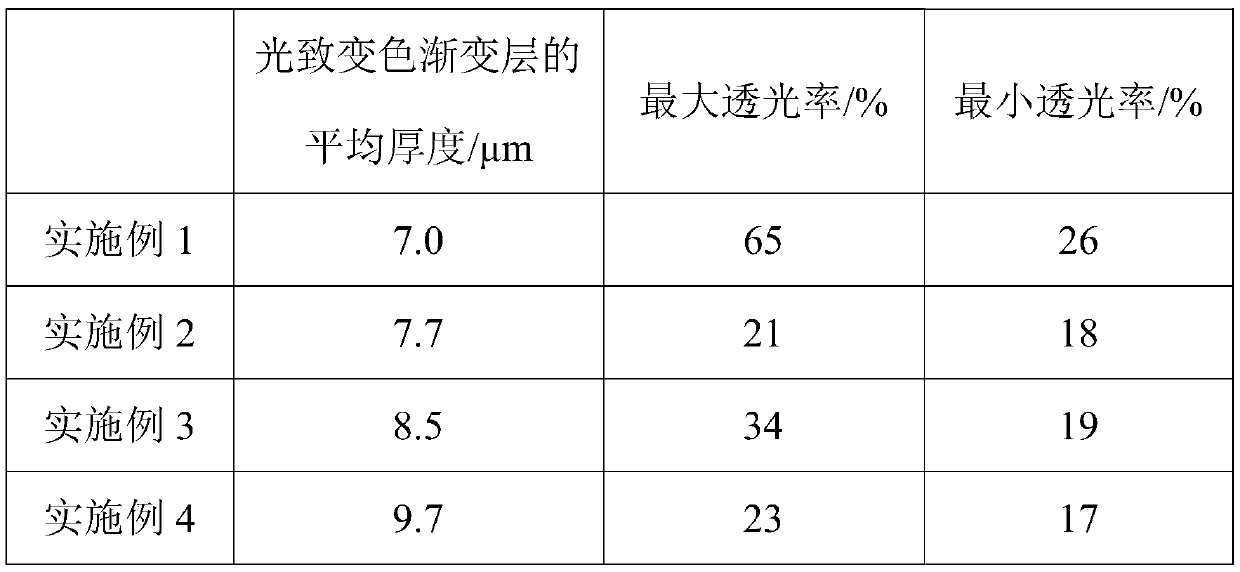

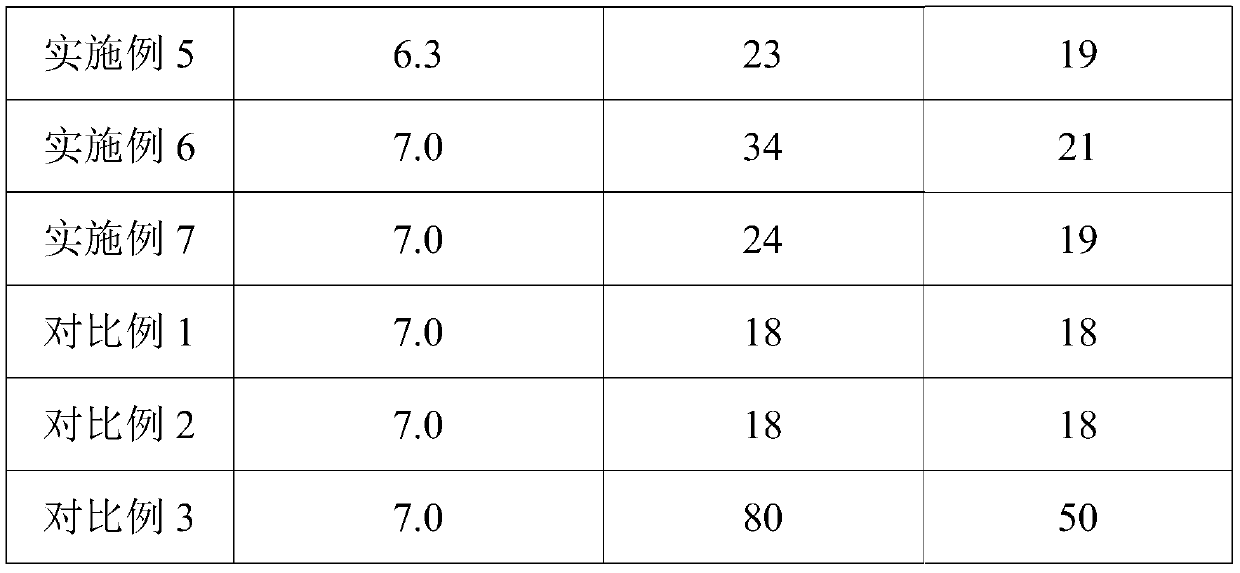

Embodiment 1

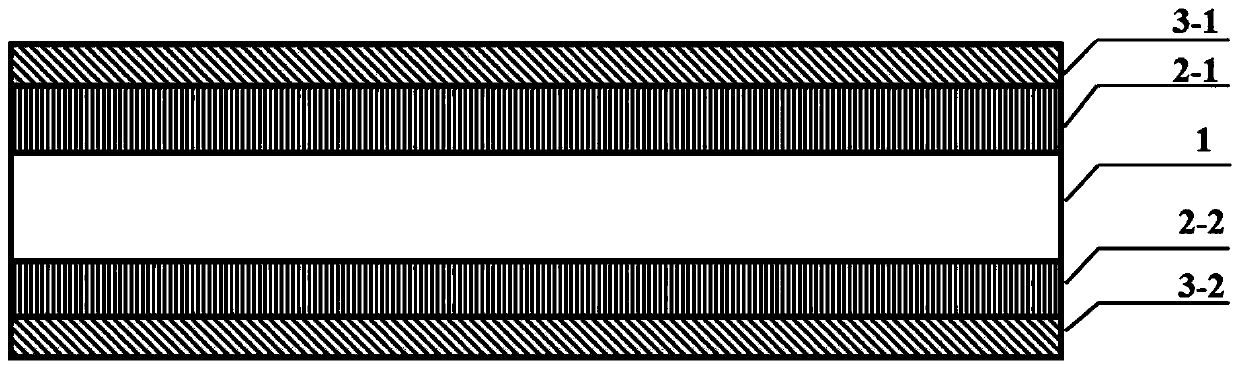

[0076] This embodiment provides a color-changing lens, the color-changing lens includes a substrate (1), a first photochromic gradient layer (2-1), a second photochromic gradient layer (2-2), a first hard reinforcement layer (3-1) and a second hard reinforcement layer (3-2); the first photochromic gradient layer (2-1) and the second photochromic gradient layer (2-1) and the second photochromic gradient layer (2-1) are arranged on both sides of the substrate (1) The color-changing gradient layer (2-2); the first hard strengthening layer (3-1) is arranged on the surface of the first photochromic gradient layer (2-1); the second photochromic gradient layer ( The surface of 2-2) is provided with the second hard strengthening layer (3-2).

[0077] The preparation method is as follows:

[0078] (1) The substrate (refractive index 1.74) was ultrasonically treated in 12% NaOH aqueous solution at 55°C for 12min, washed with pure water, dried, cooled to room temperature, placed in the ...

Embodiment 2

[0083] This embodiment provides a color-changing lens, the color-changing lens includes a substrate (1), a first photochromic gradient layer (2-1), a second photochromic gradient layer (2-2), a first hard reinforcement layer (3-1) and a second hard reinforcement layer (3-2); the first photochromic gradient layer (2-1) and the second photochromic gradient layer (2-1) and the second photochromic gradient layer (2-1) are arranged on both sides of the substrate (1) The color-changing gradient layer (2-2); the first hard strengthening layer (3-1) is arranged on the surface of the first photochromic gradient layer (2-1); the second photochromic gradient layer ( The surface of 2-2) is provided with the second hard strengthening layer (3-2).

[0084] The preparation method is as follows:

[0085] (1) The substrate (refractive index 1.67) is ultrasonically treated in 18% KOH aqueous solution at 60°C for 18min, washed with pure water, dried, cooled to room temperature, placed in the ph...

Embodiment 3

[0090] This embodiment provides a color-changing lens, which includes a substrate (1), a first photochromic gradient layer (2-1), a second photochromic gradient layer (2-2), a first hard A strengthening layer (3-1) and a second hard strengthening layer (3-2); the first photochromic gradient layer (2-1) and the second photochromic gradient layer (2-1) and the second light The first photochromic gradient layer (2-2); the first hard strengthening layer (3-1) is arranged on the surface of the first photochromic gradient layer (2-1); the second photochromic gradient layer The second hard strengthening layer (3-2) is provided on the surface of (2-2).

[0091] The preparation method is as follows:

[0092] (1) Ultrasonicate the substrate (refractive index 1.60) in 15% NaOH aqueous solution at 57°C for 15 minutes, wash with pure water, dry, cool to room temperature, place in photochromic coating solution, and dip-coat at 15°C for 10s Then pull out at a constant speed of 1.0 mm / s, dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com