Glass Gradient Spraying Process, Gradient Color Glass Cover and Electronics

A glass and process technology, applied in coating and other directions, can solve the problems of poor color and gradient transition, poor gradient appearance, orange pattern or wrinkled surface, etc., to achieve smooth color gradient transition and stable glass gradient spraying process. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

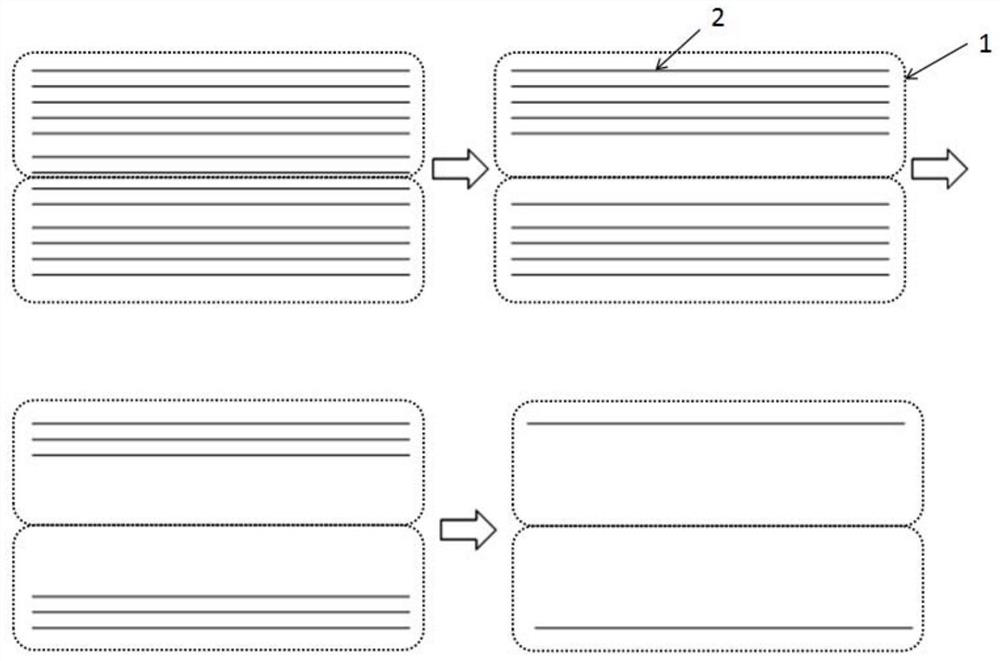

[0109] A glass gradient spraying process, comprising the following steps:

[0110] Use nano translucent ink to spray the entire surface of each glass according to 7 parallel spraying paths, and then reduce the spraying area three times, and each glass reduces 2 spraying paths each time, so that each glass forms an ink layer with a gradient thickness After the spraying is completed, the ink is baked and back-baked in a tunnel oven to obtain a gradient glass;

[0111] Among them, the viscosity of nano translucent ink is 11Pa.s;

[0112] The distance between adjacent spraying paths is 14mm; the spray width range during spraying is 2cm, and the spraying height is 8cm;

[0113] The spraying speed during spraying is 600mm / s, the ink supply pressure is 200Pa, the atomization pressure is 300Pa, and the spray pressure is 350Pa;

[0114] The baking temperature is 80°C, and the baking time is 8 minutes; the back-baking temperature is 80°C, and the back-baking time is 30 minutes; the ba...

Embodiment 2

[0117] A glass gradient spraying process, comprising the following steps:

[0118] Use nano translucent ink to spray the entire surface of each glass according to 7 parallel spraying paths, and then reduce the spraying area three times. Each glass reduces 2 spraying paths each time, so that each glass forms a spraying thickness gradient, and the spraying is completed. Finally, the ink is baked and back-baked using a tunnel oven to obtain gradient glass;

[0119] Among them, the viscosity of nano translucent ink is 10Pa.s;

[0120] The distance between adjacent spraying paths is 15mm; the spray width range during spraying is 2.5cm, and the spraying height is 8.5cm;

[0121] The spraying speed during spraying is 500mm / s, the ink supply pressure is 180Pa, the atomization pressure is 300Pa, and the spray pressure is 320Pa;

[0122] The baking temperature is 75°C, and the baking time is 10 minutes; the back-baking temperature is 75°C, and the back-baking time is 35 minutes; the b...

Embodiment 3

[0125] A glass gradient spraying process, comprising the following steps:

[0126] Use nano-translucent ink to spray the entire surface according to 10 parallel spraying paths for each glass, and then reduce the spraying area three times. Each glass reduces 3 spraying paths each time, so that each glass forms a spraying thickness gradient, and the spraying is completed. Finally, the ink is baked and back-baked using a tunnel oven to obtain gradient glass;

[0127] Among them, the viscosity of nano translucent ink is 12Pa.s;

[0128] The distance between adjacent spraying paths is 16mm; the spray width range during spraying is 3cm, and the spraying height is 8cm;

[0129] When spraying, the spraying speed is 700mm / s, the ink supply pressure is 220Pa, the atomization pressure is 320Pa, and the spray pressure is 380Pa;

[0130] The baking temperature is 85°C, and the baking time is 6 minutes; the back-baking temperature is 85°C, and the back-baking time is 25 minutes; the bakin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com