Anti-cracking method for woods

A wood and anti-cracking technology, applied in the direction of wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of grinding off the treatment layer, destroying the appearance of wood furniture, lack of natural color of the comb, and achieving the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

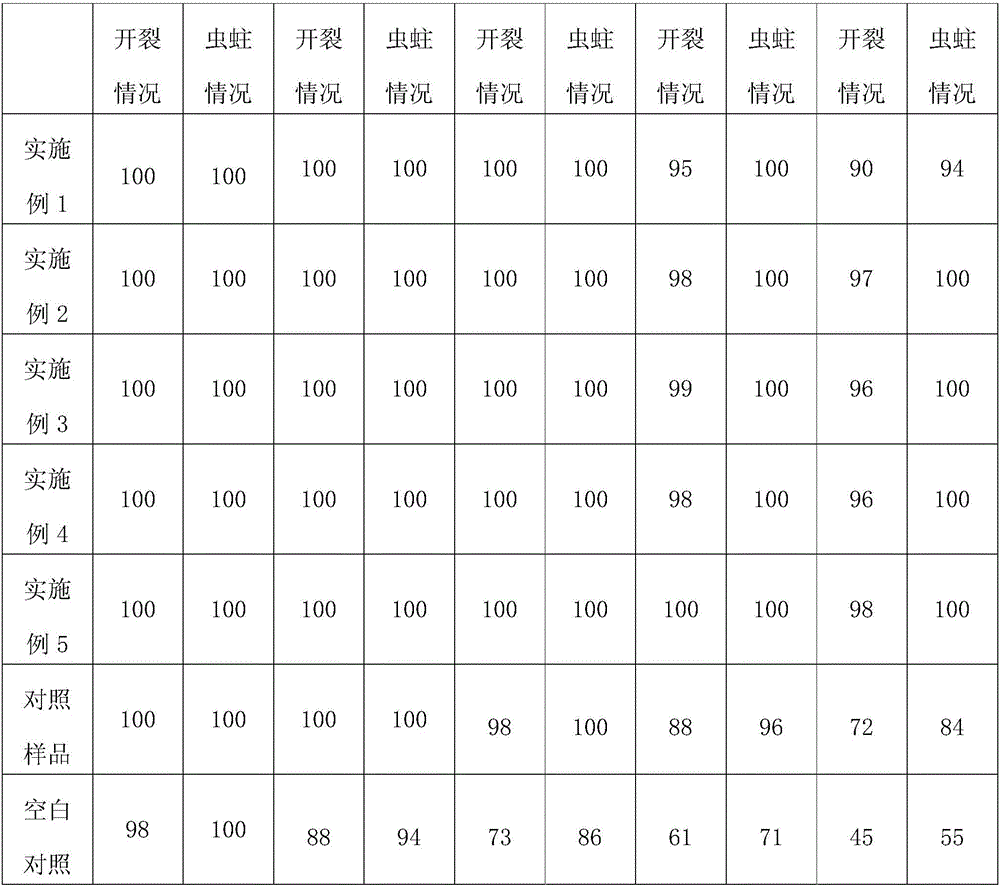

Embodiment 1

[0029] A method for preventing cracking of wood, comprising the following steps:

[0030] a. Log processing: first take the log that needs to be cracked, and dry it in the shade until the moisture content of the wood is lower than 60%, then cut the log into boards according to the required size, and the thickness of the board is 5cm; set aside.

[0031] b. Plate drying: take the plate described in step a, and dry it for 3 days with a reduced-pressure drying method to obtain a dried plate for future use; wherein, the parameters of the drying method are that the pressure is 2.67kpa, and the temperature is 30°C.

[0032] c. Anti-cracking treatment: Take the dry board described in step b, soak it with wood anti-cracking agent at a temperature of 25°C for 2 days, then take it out and place it in a pressurized environment for 10 hours, the pressurized pressure is 110kpa, and finally move it indoors and dry it in the shade To the desired moisture content, the board has to be treated....

Embodiment 2

[0036] A method for preventing cracking of wood, comprising the following steps:

[0037] a. Log processing: First take the log that needs to be cracked, dry it in the shade until the moisture content of the wood is lower than 60%, then cut the log into boards according to the required size, and the thickness of the board is 10cm; set aside.

[0038] b. Plate drying: take the plate described in step a, and dry it for 7 days by vacuum drying method to obtain a dry plate for future use; wherein, the parameters of the drying method are that the pressure is 60kpa, and the temperature is 60°C.

[0039] c. Anti-cracking treatment: Take the dry board described in step b, soak it with wood anti-cracking agent at a temperature of 40°C for 8 days, then take it out and place it in a pressurized environment for 36 hours, the pressurized pressure is 130kpa, and finally move it indoors and dry it in the shade To the desired moisture content, the board has to be treated.

[0040] d. Finishe...

Embodiment 3

[0043] A method for preventing cracking of wood, comprising the following steps:

[0044] a. Log processing: First take the log that needs to be cracked, dry it in the shade until the moisture content of the wood is lower than 60%, then cut the log into boards according to the required size, and the thickness of the board is 7.5cm; set aside.

[0045] b. Plate drying: take the plate described in step a, and dry it for 5 days with a reduced-pressure drying method to obtain a dried plate for future use; wherein, the parameters of the drying method are that the pressure is 30kpa, and the temperature is 45°C.

[0046] c. Anti-cracking treatment: Take the dry board described in step b, soak it with wood anti-cracking agent at a temperature of 32.5°C for 5 days, then take it out and place it in a pressurized environment for 23 hours, the pressurized pressure is 120kpa, and finally move it indoors and dry it in the shade To the desired moisture content, the board has to be treated. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com