Super-hydrophobic nanometer transparent coating and preparation method thereof

A technology of transparent coating and super-hydrophobic coating, applied in coating, coating dipping, pigment-containing coating, etc., can solve the problems of high production cost, complicated preparation process and harsh reaction conditions of super-hydrophobic coating, and achieve the Low cost, simple coating process and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

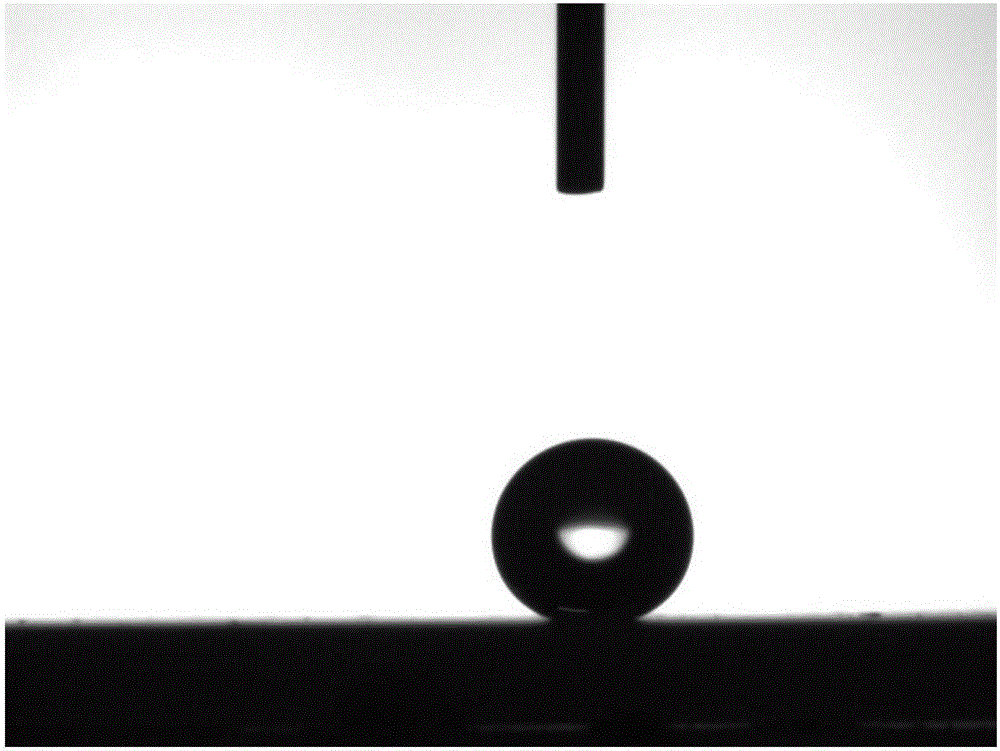

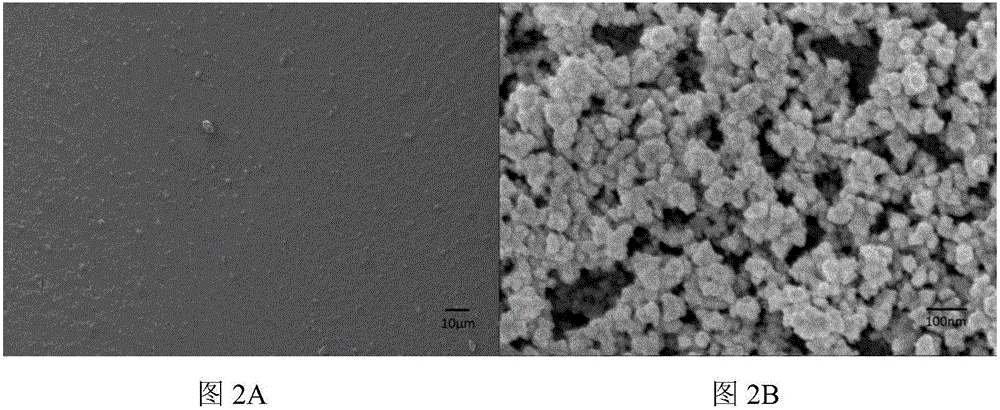

[0027] The invention provides a superhydrophobic nano transparent coating and a preparation method thereof, the preparation method comprising the steps of:

[0028] In the first step, 0.25 to 0.33 parts of the first type of inorganic nanoparticles are added to 25 to 28 parts of organic solvents, and ultrasonically dispersed to obtain the first solution; then 2.5 parts of dispersants and 0.1 parts of the second type of inorganic nanoparticles Add it to the above first solution, and ultrasonically disperse to obtain a dispersion. The second type of inorganic nanoparticles is preferably lipophilic SiO 2 Nanoparticles.

[0029] In the second step, 0.25-0.33 parts of cross-linking agent and 0.6 parts of additives are added to the dispersion liquid, and ultrasonically dispersed; then 0.4-0.5 parts of low surface energy polymers are added and mixed evenly to obtain a transparent and clear super-hydrophobic coating. The additive is preferably 0.5 part of ethanol and 0.1 part of glac...

Embodiment 1

[0033] Apply the preparation method provided by the invention to prepare superhydrophobic nano transparent coating, the specific steps are as follows:

[0034] In the first step, 0.25 parts of gas-phase SiO 2Nanoparticles (7nm) were added to 28 parts of N,N-dimethylformamide organic solvent, and ultrasonically dispersed for 10 minutes to obtain the first solution; then 2.5 parts of dispersant Nanosil 9009 and 0.1 part of lipophilic SiO 2 Nanoparticles (200 nm) were added to the above first solution, and ultrasonic dispersion was continued for 10 minutes to obtain a dispersion.

[0035] In the second step, add 0.33 parts of methyltrimethoxysilane crosslinking agent, 0.5 parts of ethanol and 0.1 part of glacial acetic acid to the above dispersion liquid, and continue ultrasonic dispersion for 10 minutes; add 0.4 parts of low surface energy polymer ten Dithiol, continue to sonicate for 10 minutes to obtain a transparent and clear super-hydrophobic coating.

[0036] The third st...

Embodiment 2

[0038] In the first step, 0.3 parts of TiO 2 Nanoparticles (20nm) were added to 25 parts of xylene organic solvent, and ultrasonically dispersed for 10 minutes to obtain the first solution; then 2.5 parts of dispersant Nanosil 9009 and 0.1 part of lipophilic SiO 2 Nanoparticles (200 nm) were added to the above first solution, and ultrasonic dispersion was continued for 10 minutes to obtain a dispersion.

[0039] In the second step, add 0.33 parts of methyldimethoxysilane crosslinking agent, 0.5 parts of ethanol and 0.1 parts of ammonia water to the dispersion liquid, and continue ultrasonic dispersion for 10 minutes; add 0.4 parts of low surface energy polymer before coating FAS, continue to sonicate for 10 minutes to obtain a transparent and clear super-hydrophobic coating. The mass concentration of the ammonia water is 20%.

[0040] The third step is to apply the super-hydrophobic coating on the slide of the glass substrate by dipping and pulling, and dry it in an oven at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com