Super-hydrophobic composite coating, and preparation method and application thereof

A composite coating and super-hydrophobic technology, applied in the field of composite coatings, can solve problems such as insufficient adhesion, complicated process, and shedding, and achieve excellent wear resistance and hydrophobicity, convenient use, and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

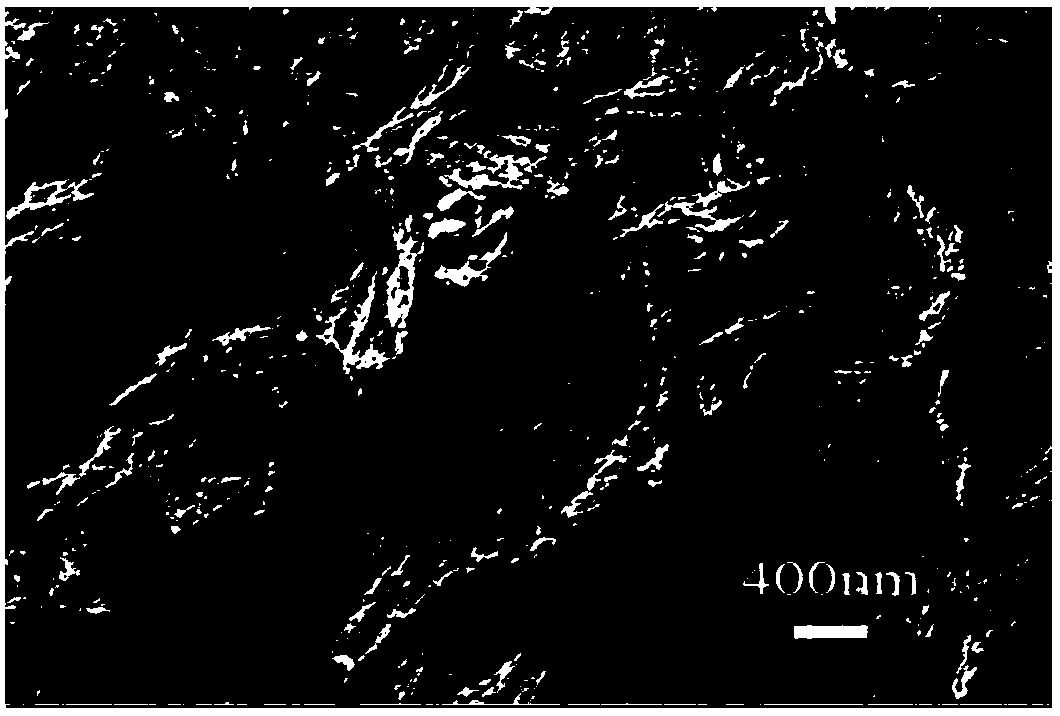

[0040] CNC-SiO 2 Preparation of Superhydrophobic Composite Coatings

[0041]Use diameter to be 3nm-5nm, length is the nano-cellulose whisker (CelluloseNanocrystal, CNC) of 100nm-300nm to be formulated into the aqueous suspension that CNC concentration is 4wt%, the CNC aqueous suspension that configures is placed in molecular weight cut-off 12000- 14000 dialysis bag, with absolute ethanol for dialysis. The time of each dialysis treatment is 12 hours, and a total of 6 dialysis treatments are carried out. After the treatment is completed, the ethanol suspension of CNC is obtained by fully stirring. Then, it was heated in a water bath to volatilize the ethanol, and it was prepared into an ethanol suspension with a CNC concentration of 1 wt%.

[0042] Take 50 mL of the above-mentioned CNC suspension in ethanol with a concentration of 1 wt%, mix it with 3 mL of 25% ammonia water, and stir at 50°C for 20 minutes, then add 3 mL of tetraethyl orthosilicate (analytical grade, the same...

Embodiment 2

[0047] CNC-SiO 2 Preparation of Superhydrophobic Composite Coatings

[0048] Use a CNC with a diameter of 3nm-5nm and a length of 100nm-300nm to prepare an aqueous suspension with a CNC concentration of 4wt%, place the configured CNC aqueous suspension in a dialysis bag with a molecular weight cut-off of 12000-14000, and use absolute ethanol Perform dialysis. The time of each dialysis treatment is 24 hours, and the dialysis treatment is carried out 3 times in total. After the treatment is completed, the ethanol suspension of CNC is obtained by fully stirring. Then it was diluted with anhydrous ethanol to prepare CNC with a concentration of 3wt% ethanol suspension.

[0049] Take 50mL of the above-mentioned CNC with a concentration of 3wt% ethanol suspension, mix it with 8mL of 25% ammonia water, and stir at 50°C for 20 minutes, then add 8mL tetraethyl orthosilicate and continue stirring for 2 hours to obtain a CNC-SiO 2 complex suspension.

[0050] Then add 2 mL of POTS and...

Embodiment 3

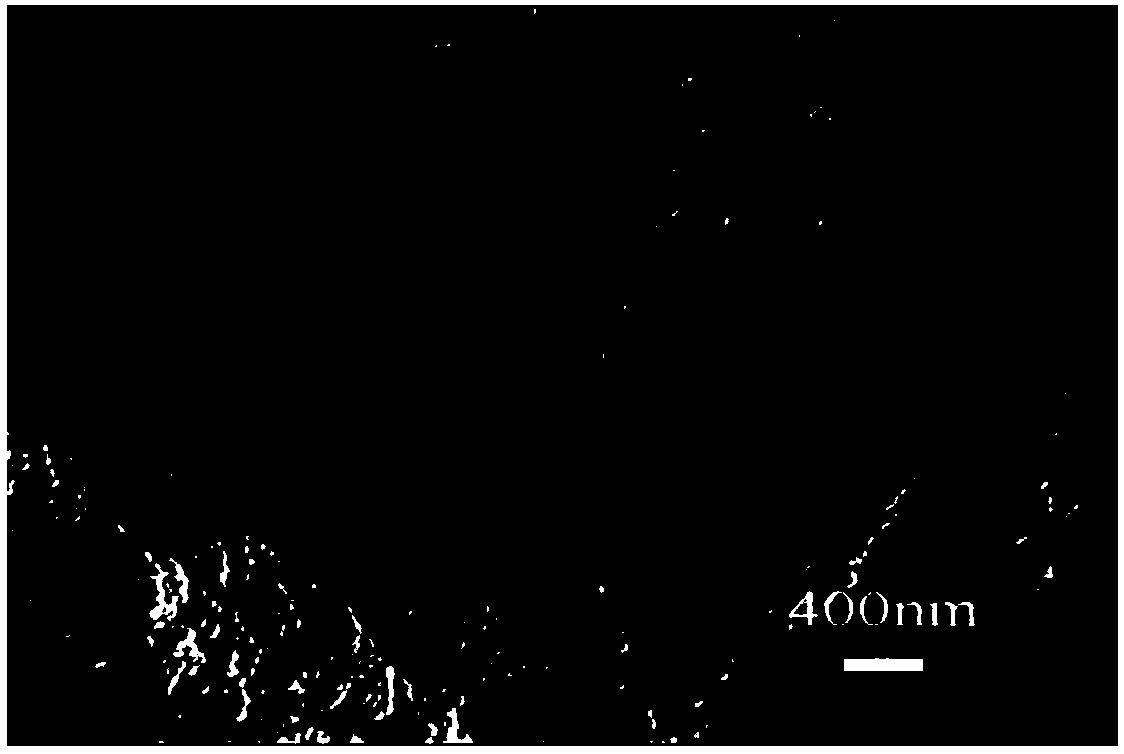

[0054] CNC-SiO 2 Preparation of Superhydrophobic Composite Coatings

[0055] Use a CNC with a diameter of 3nm-5nm and a length of 100nm-300nm to prepare an aqueous suspension with a CNC concentration of 3wt%, place the configured CNC aqueous suspension in a dialysis bag with a molecular weight cut-off of 12000-14000, and use absolute ethanol Perform dialysis. The time of each dialysis treatment is 18 hours, and a total of 4 dialysis treatments are carried out. After the treatment is completed, the ethanol suspension of CNC is obtained by fully stirring. Then by diluting with absolute ethanol, it is formulated into CNC ethanol suspension with the concentration of CNC being 2wt%.

[0056] Take 50mL of CNC ethanol suspension with a concentration of 2wt%, mix it with 4mL of 25% ammonia water, stir at 50°C for 20 minutes, then add 4mL of tetraethyl orthosilicate and continue stirring for 1.5 hours to obtain a CNC-SiO 2 complex suspension.

[0057] Then add 1 mL of POTS and cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com