Blue stain and mildew preventing processing method for masson pine timber

A treatment method and technology for masson pine, which are applied in the directions of impregnated wood, wood impregnation, wood processing appliances, etc., can solve problems such as limitation and affect the appearance of wood, and achieve the effects of reducing concentration, good mold inhibition effect and simple formula.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

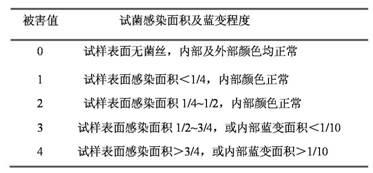

Image

Examples

Embodiment 1

[0017] The configuration mass percentage is 0.05% thiophanate-methyl + 0.05% carbendazim + 0.50% didecyldimethylammonium chloride anti-blue stain and anti-mold liquid: thiophanate-methyl is 70% wettable powder 0.3g , Carbendazim is 50% wettable powder 0.3g, didecyl dimethyl ammonium chloride is 98% solution 3g, add water to make 600g anti-mold liquid, stir evenly. Masson pine raw material 100mm×20mm×20mm, planed, without drying, treated by cold soaking method, soaking time 10-20min, stacked according to conventional methods, naturally dried, placed indoors, can achieve long-term anti-blueing and anti-mildew effect bacteria effect.

Embodiment 2

[0019] The configuration mass percentage is 0.05% thiophanate-methyl + 0.05% carbendazim + 0.50% didecyldimethylammonium chloride anti-blue stain and anti-mold liquid: thiophanate-methyl is 70% wettable powder 0.3g , Carbendazim is 50% wettable powder 0.3g, didecyl dimethyl ammonium chloride is 98% solution 3g, add 75% alcohol to make 600g anti-mold liquid. The solvent is alcohol, thiophanate-methyl and carbendazim have a better dissolution effect, and the anti-blue stain and anti-mildew solution configured has a more significant control effect. The masson pine raw wood is 100mm×20mm×20mm, without drying, treated by cold soaking method, soaking time for 10-20min, stacked according to conventional methods, dried naturally, and placed indoors, which can achieve long-term anti-blueing and anti-mildew antibacterial effect.

Embodiment 3

[0021] The configuration mass percentage is 0.10% thiophanate-methyl + 0.10% carbendazim + 1.00% didecyldimethylammonium chloride anti-blue stain and anti-mold liquid: thiophanate-methyl is 70% wettable powder 0.6g , carbendazim is 0.6g of 50% wettable powder, didecyl dimethyl ammonium chloride is 6g of 98% solution, add water to make 600g of anti-mold liquid, and stir evenly. Masson pine raw material 100mm×20mm×20mm, planed, without drying, treated by cold soaking method, soaking time 10-20min, stacked according to conventional methods, naturally dried, placed indoors, can achieve long-term anti-blueing and anti-mildew effect bacteria effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com