Winding device and square power battery cell winding machine

A winding device and winding head technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of potential safety hazards, collision of the push-closing needle unit, difficult needle winding, etc., to ensure the quality of glue sticking, prevent swaying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Example of winding device:

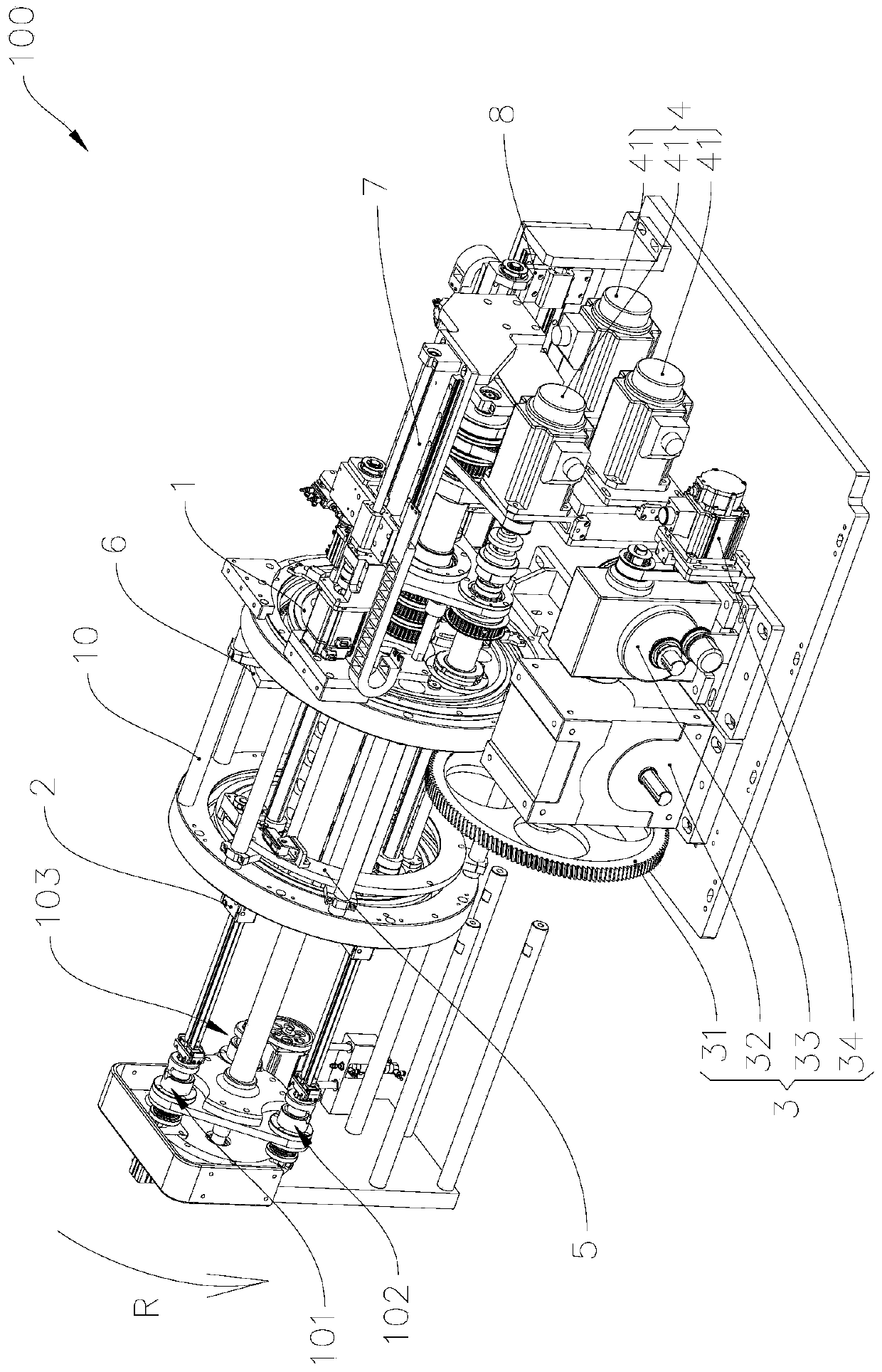

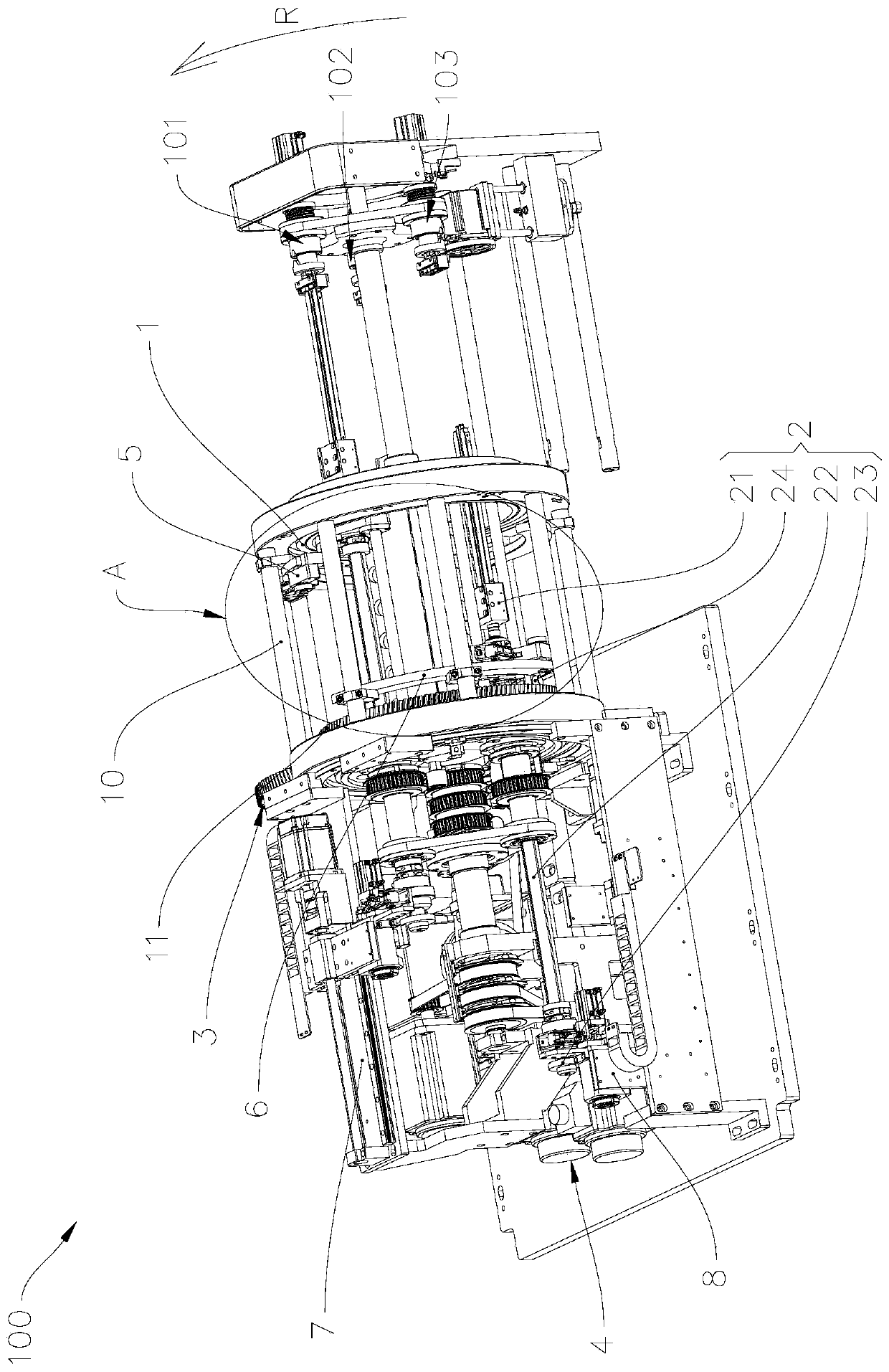

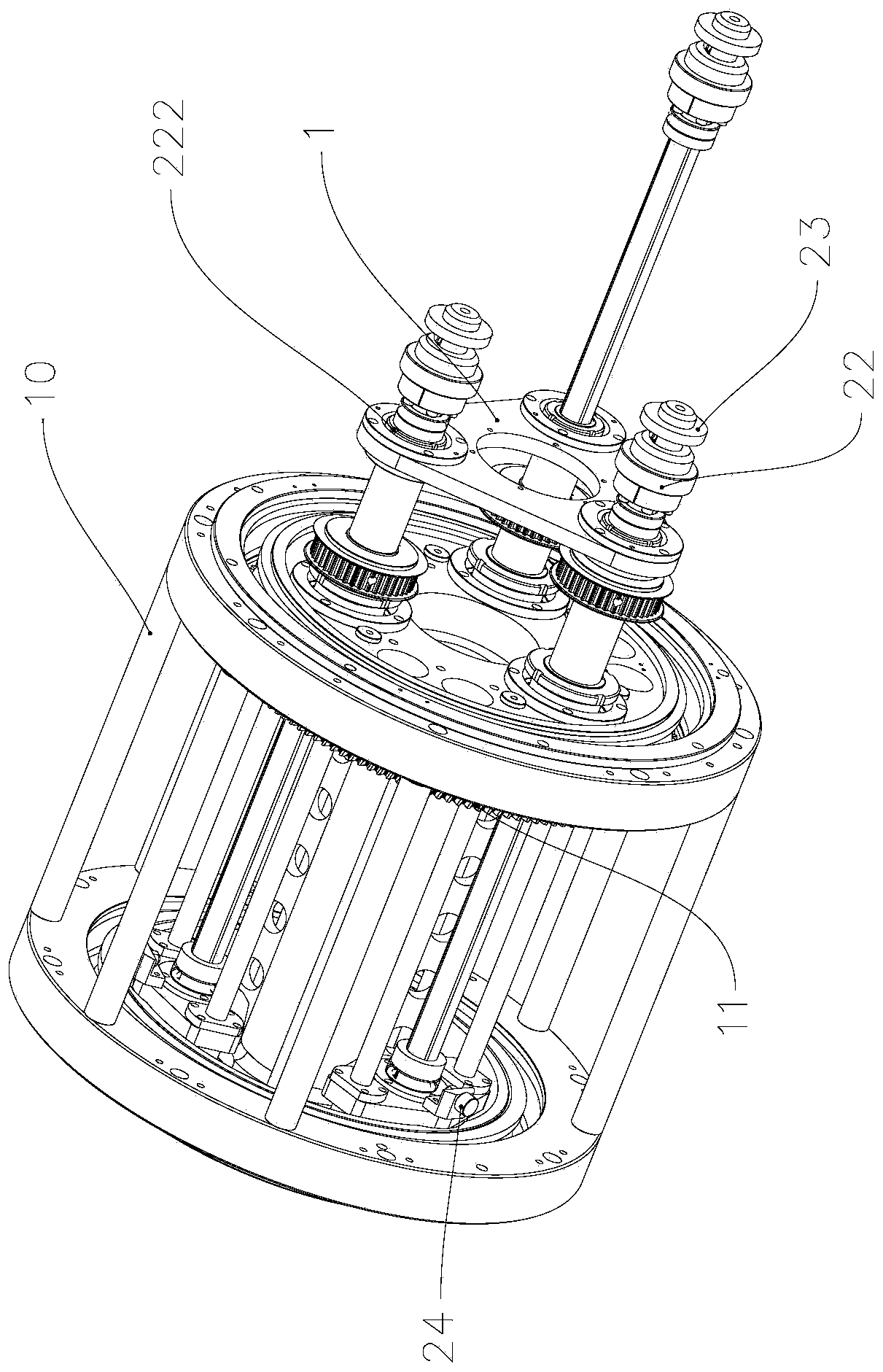

[0040] refer to Figure 1 to Figure 3 , the winding device 100 includes a frame 10, a winding head 1, a winding needle 2, a reversing unit 3, a driving unit 4, a first limit unit 5, a second limit unit 6, a push-close needle unit 7 and an open and draw needle unit 8. Wherein, the winding device 100 has a winding station 101, a gluing station 102 and a blanking station 103, and the positions of the winding station 101, the gluing station 102 and the blanking station 103 are relative to the frame 10 stable.

[0041] The winding head 1 is rotatably mounted on the frame 10 around its own axis, the number of winding needles 2 is three, and the three winding needles 2 are installed on the winding head 1 along the axis of the winding head 1 and along the winding head 1 Evenly distributed in the axial direction, each winding needle 2 can rotate relative to the winding head 1 around its own axis, and each winding needle 2 can slide relative to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com