Glue outlet control method of gluing machine and glue outlet control device

A control method and a technology of a control device, which are applied to the device and coating of the surface coating liquid, can solve the problems that plague construction enterprises, such as huge size, waste of colloid, etc., and achieve the prevention of pollution of the working environment, accurate and clean glue control, The effect of preventing colloid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

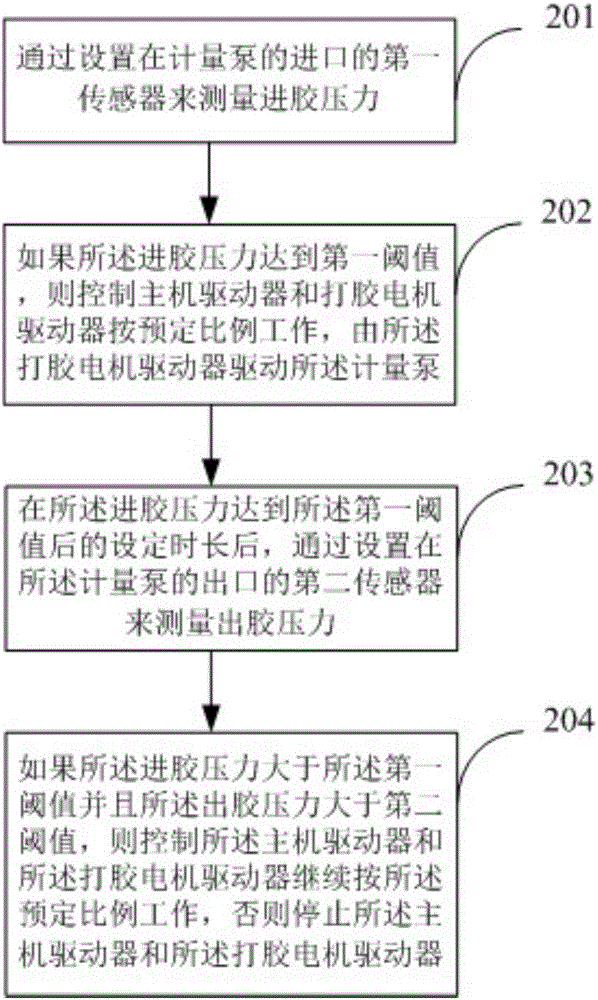

[0032] figure 2 It is a flow chart of the steps of the method embodiment of the present invention, such as figure 2 As shown, the embodiment of the present invention provides a method for controlling glue output of a glue applicator, including:

[0033] Step 201, measure the glue feeding pressure through the first sensor arranged at the inlet of the metering pump;

[0034] Step 202, if the glue feeding pressure reaches the first threshold, control the driver of the main engine and the glue-making motor driver to work in a predetermined ratio, and the glue-making motor driver drives the metering pump;

[0035] Step 203, measuring the glue discharge pressure through a second sensor arranged at the outlet of the metering pump after the glue feed pressure reaches the first threshold for a set period of time;

[0036] Step 204, if the glue-feeding pressure is greater than the first threshold and the glue-discharging pressure is greater than the second threshold, then control th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com