High-speed paper bag bottom gluing device

A gluing device and paper bag technology, applied in packaging, papermaking, bag making operations, etc., can solve problems affecting the speed of paper bags, easily damaged machines, blockages, etc., and achieve the effects of ensuring gluing quality, solving efficiency, and facilitating folding and forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The high-speed paper bag bottom gluing device of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

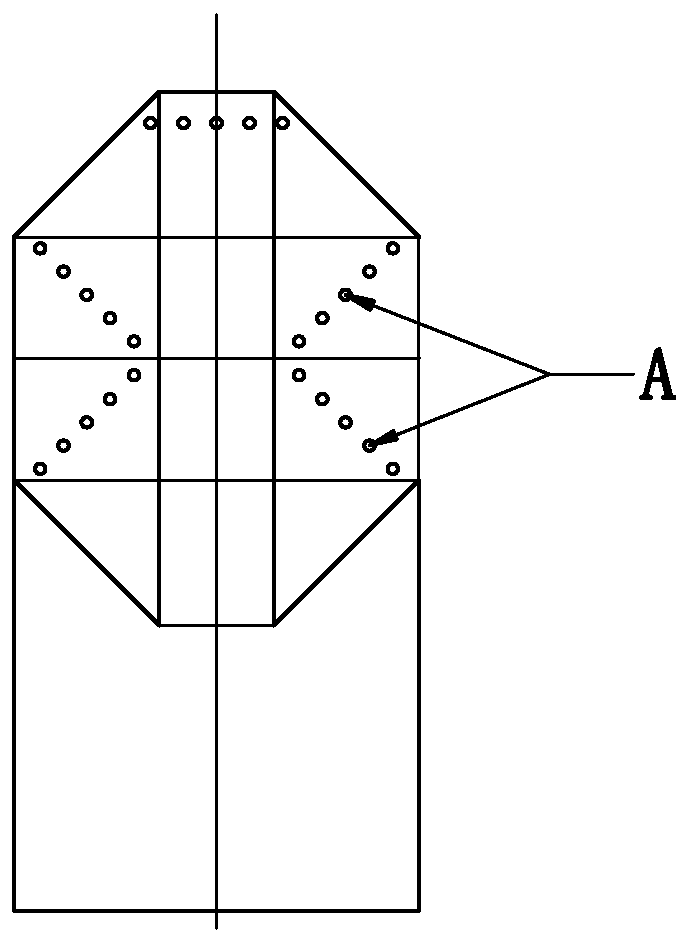

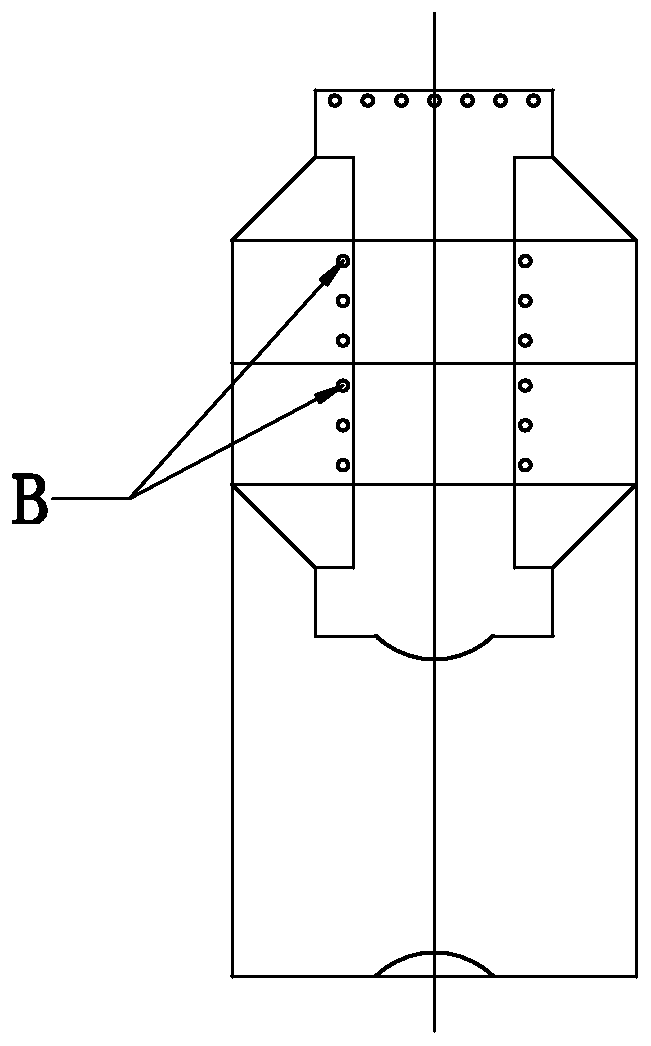

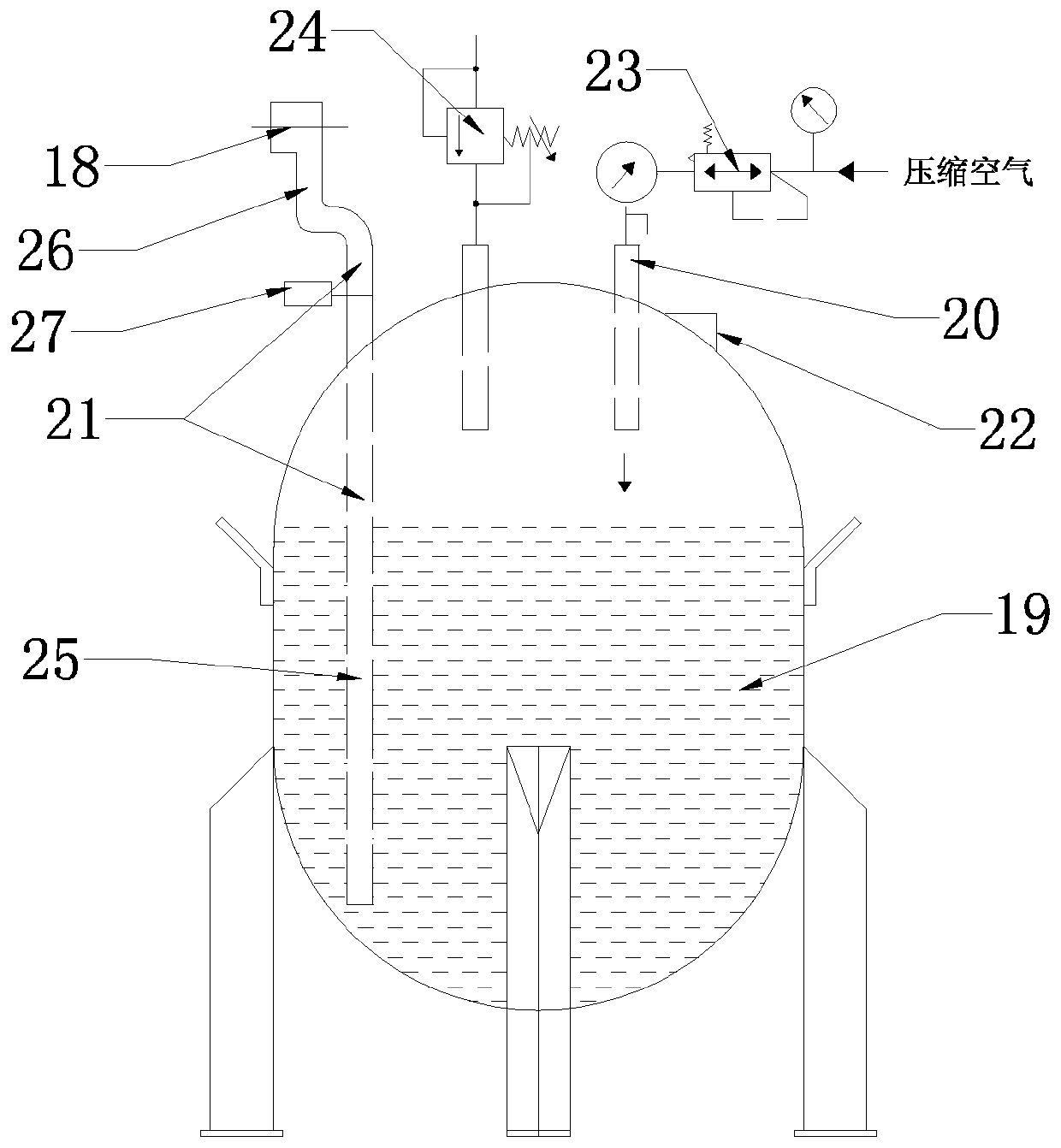

[0024] As shown in the figure, the high-speed paper bag bottom gluing device of the present invention includes a gluing shaft 2 with a glue inlet pipeline 1, a gluing roller 3 sleeved on the gluing shaft, and a plurality of gluing rollers arranged on the periphery of the gluing roller. The glue spray head 4 can be designed according to the specifications of the paper bag with several differently arranged glue spray heads 4. The glue spray roller 3 is sealed and installed on the sizing shaft and there is a gap between the glue spray roller and the sizing shaft so that the glue can enter from the glue. The annular cavity 5 into which the pipeline enters is formed by Figure 4 It can be seen that the glue inlet pipeline 1 is opened from one end of the gluing shaft and extends to the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com