Overbending correcting forming method for variable-section arc glue laminated wood member

A molding method and glued wood technology, applied in chemical instruments and methods, other plywood/plywood appliances, wood processing appliances, etc., can solve the problems of unfavorable mechanical properties of components, the inability to effectively guarantee the quality of gluing, and large shape errors of curved components, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

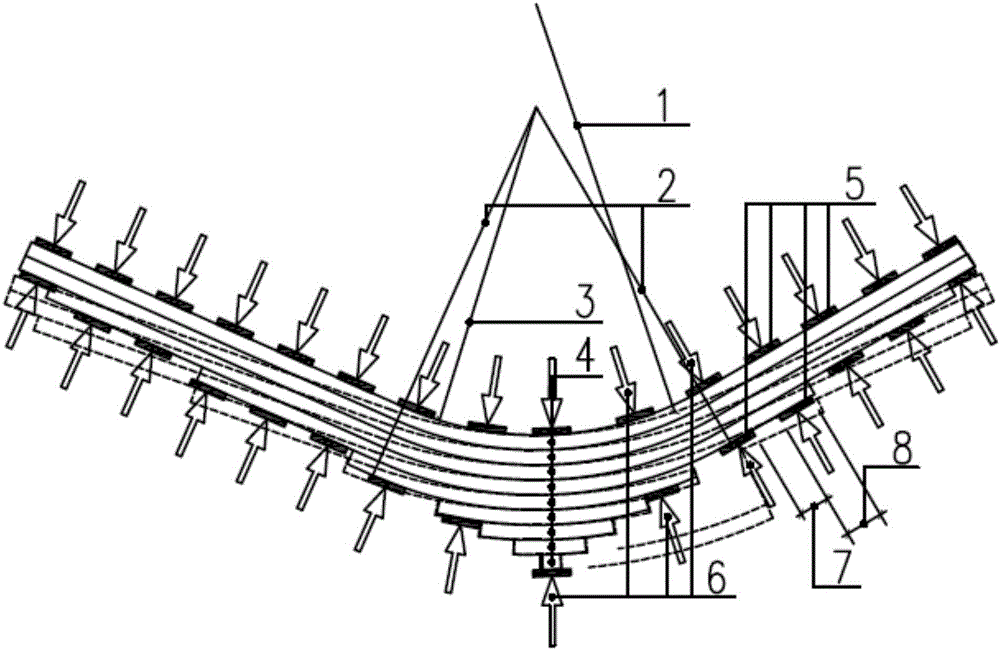

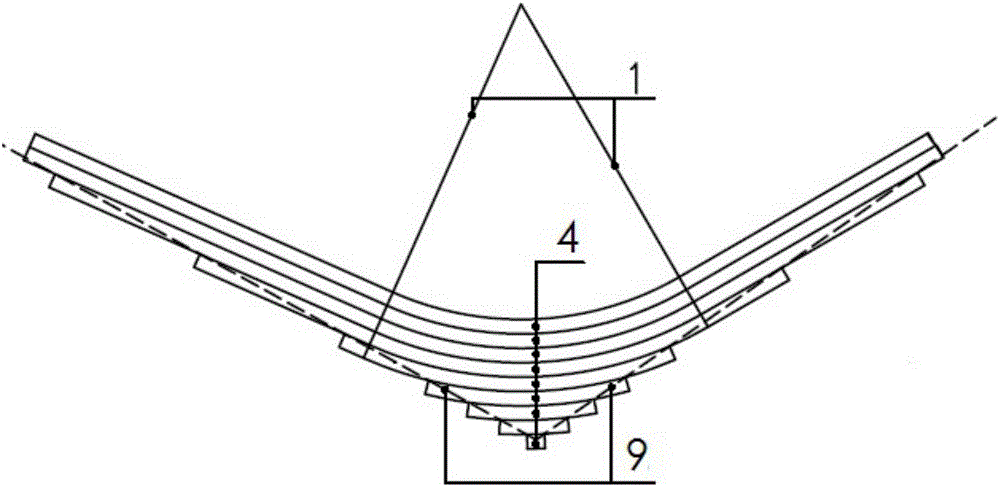

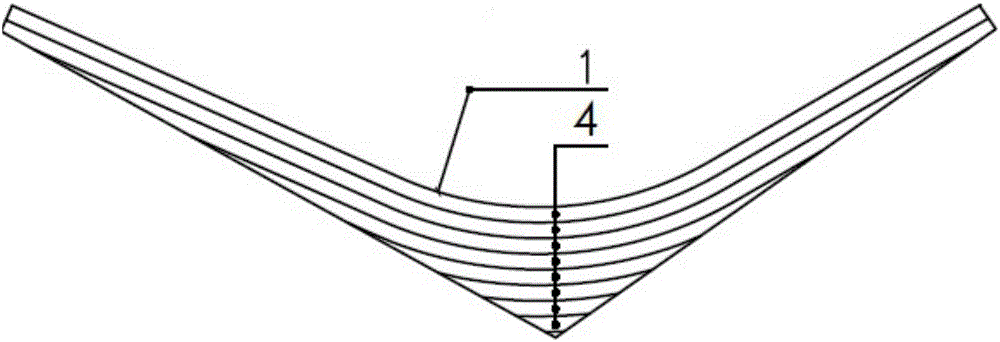

[0031] The bending correction forming method of variable cross-section arc-shaped glulam members includes five processes of length fixing of wooden laminates, adhesive coating, profiling of wooden laminates, pressurization and setting, and pressure relief maintenance. The five processes are all performed at a temperature of It is completed under the environmental conditions of 18°C and relative humidity of 60%.

[0032] For moisture content and air-dry density of 8% and 0.45g / cm 3 The design radius of curvature of the arc-shaped glulam member with variable cross-section is 5500mm, the span at the arc is 3.0m, the thickness of the thickest section of the variable-section arc-shaped glulam member is 350mm, and the number of laminates at the thickest section is 9 layers, each with a thickness of 38.8 mm, through the method of springback deformation compensation, the radius of curvature for the preparation of variable-section arc-shaped glulam members is determined as:

[0033]...

Embodiment 2

[0040] The bending correction molding method of variable cross-section arc-shaped glulam members, the steps are the same as in Example 1, including five processes of wood laminate length fixing, adhesive coating, wooden laminate profiling, pressure setting and pressure relief maintenance. Each process is completed under the environmental conditions that the temperature is 28° C. and the relative humidity is 65%.

[0041] For moisture content and air-dry density of 10% and 0.50g / cm 3 The design radius of curvature of the curved glulam member with variable cross-section is 4000mm, the span at the arc is 4.0m, the thickness of the thickest part of the cross-section curved glulam member is 400mm, and the number of laminates at the thickest part is 11 layers, each with a thickness of 36.3 mm, through the method of springback deformation compensation, the curvature radius of the curved glulam member with variable cross-section is determined as:

[0042] The radius of curvature of t...

Embodiment 3

[0046] The bending correction molding method of variable cross-section arc-shaped glulam members, the steps are the same as in Example 1, including five processes of wood laminate length fixing, adhesive coating, wooden laminate profiling, pressure setting and pressure relief maintenance. Each process is completed under the environmental conditions that the temperature is 25° C. and the relative humidity is 85%.

[0047] For moisture content and air-dry density of 12% and 0.60g / cm 3 The design radius of curvature of the curved glulam member with variable cross-section is 6000mm, the span at the arc is 5.8m, the thickness of the thickest part of the cross-section curved glulam member is 600mm, and the number of laminates at the thickest part is 17 layers, the thickness of each layer is 35.2 mm, and the radius of curvature of the curved glulam member with variable cross-section is determined by means of springback deformation compensation:

[0048] The radius of curvature of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com