A kind of flame retardant toughening agent and the epoxy curing agent and beautifying agent epoxy resin composition prepared by the same

A technology of epoxy curing agent and epoxy resin, which is applied in the field of epoxy resin and can solve the problems of non-flame retardancy and insufficient toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

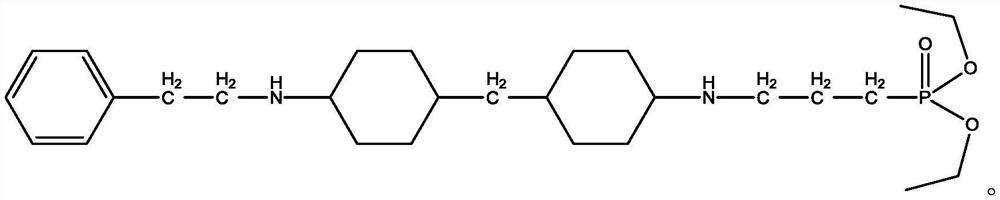

[0069] (1) Preparation of flame retardant toughening agent

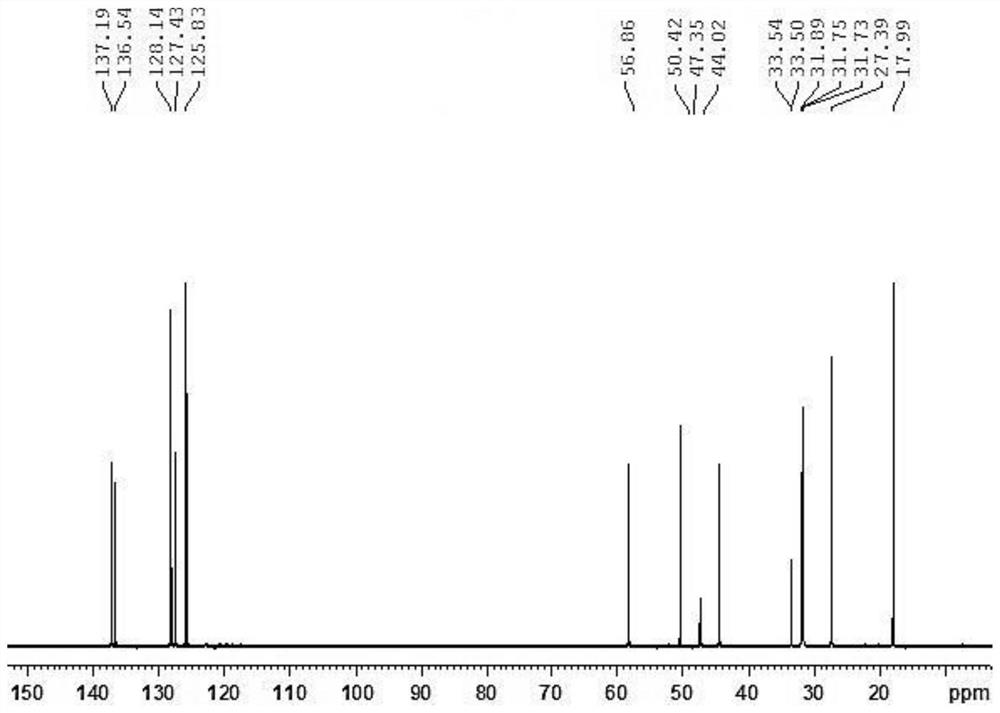

[0070] S1: Under the protection of nitrogen, the reaction pressure is controlled at 1MPa, and 210g H 12 MDA was reacted with 104 g of styrene under reflux of 200 g of ethanol at 100°C for 12 hours, and the ethanol was removed by rotary evaporation to obtain the reaction intermediate M. The characterization results of intermediate M are shown in the appendix figure 1 .

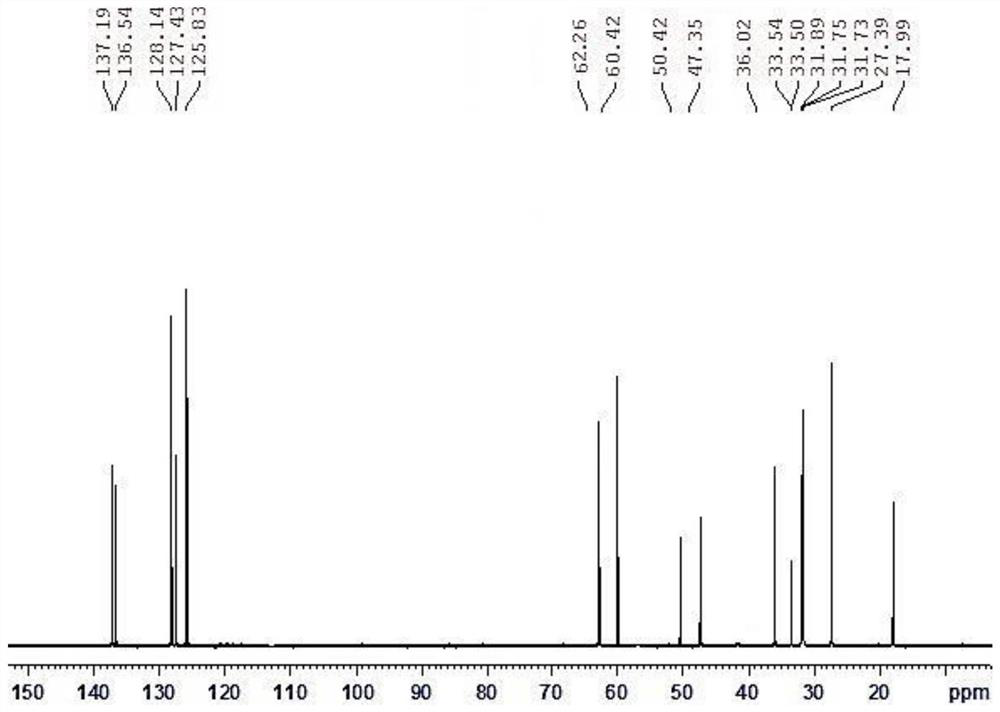

[0071] S2: Under the protection of nitrogen, 314g of intermediate M and 178g of diethyl allyl phosphate were catalyzed by 1.2g of phosphoric acid in 400g of ethanol, and reacted at 100°C for 12h, and the ethanol was removed by rotary evaporation to obtain the target toughening agent. The characterization results of the target product toughener are shown in the attached figure 2 .

[0072] (2) Preparation of epoxy curing agent

[0073] Will 8100 polyetheramine 10g, H 12 MDA 20g, benzyl alcohol 25g, E51 epoxy resin 15g, stir at 300rpm for 20min...

Embodiment 2

[0079] (1) Preparation of flame retardant toughening agent

[0080] S1: Under the protection of nitrogen, the reaction pressure is controlled at 1MPa, and 210g H 12 MDA and 109g styrene were reacted in 300g ethanol at 80°C for 8h, and the ethanol was removed by rotary evaporation to obtain the reaction intermediate M.

[0081] S2: Under the protection of nitrogen, 300g of intermediate M and 187g of allyl diethyl phosphate were catalyzed by 1.2g of phosphoric acid in 300g of ethanol, and reacted at 80°C for 8h, and the ethanol was removed by rotary evaporation to obtain the target toughening agent.

[0082] (2) Preparation of epoxy curing agent

[0083] Will 8100 polyetheramine 15g, H 12 15g of MDA, 25g of benzyl alcohol, 15g of E51 epoxy resin, stirred at 300rpm for 20min and mixed evenly, kept at 80°C for 2h, cooled to room temperature, added 10g of toughening agent, 20g of dodecylphenol, stirred at 300rpm for 20min and mixed to obtain epoxy Hardener.

[0084] (3) Prepa...

Embodiment 3

[0089] (1) Preparation of flame retardant toughening agent

[0090] S1: Under the protection of nitrogen, the reaction pressure is controlled at 1MPa, and 210g H 12 MDA and 109g styrene were reacted in 300g ethanol at 120°C for 10h, and the ethanol was removed by rotary evaporation to obtain the reaction intermediate M.

[0091] S2: Under the protection of nitrogen, 300g of intermediate M and 180g of allyl diethyl phosphate were catalyzed by 1.2g of phosphoric acid in 300g of ethanol, and reacted at 120°C for 8h, and the ethanol was removed by rotary evaporation to obtain the target toughening agent.

[0092] (2) Preparation of epoxy curing agent

[0093] Will 8100 polyetheramine 15g, H 12 MDA 10g, benzyl alcohol 30g, E51 epoxy resin 10g, stir at 300rpm for 20min to mix evenly, keep warm at 80°C for 2h, add 15g of toughening agent after cooling to room temperature, 20g of nonylphenol, stir at 300rpm for 20min and mix to obtain epoxy curing agent .

[0094] (3) Preparatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com