Adhesive having rapid fixing structure, and preparation method thereof

A positioning structure and adhesive technology, applied in the direction of adhesives, polyether adhesives, adhesive types, etc., can solve problems such as large internal stress, warpage, and large shrinkage of adhesive parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

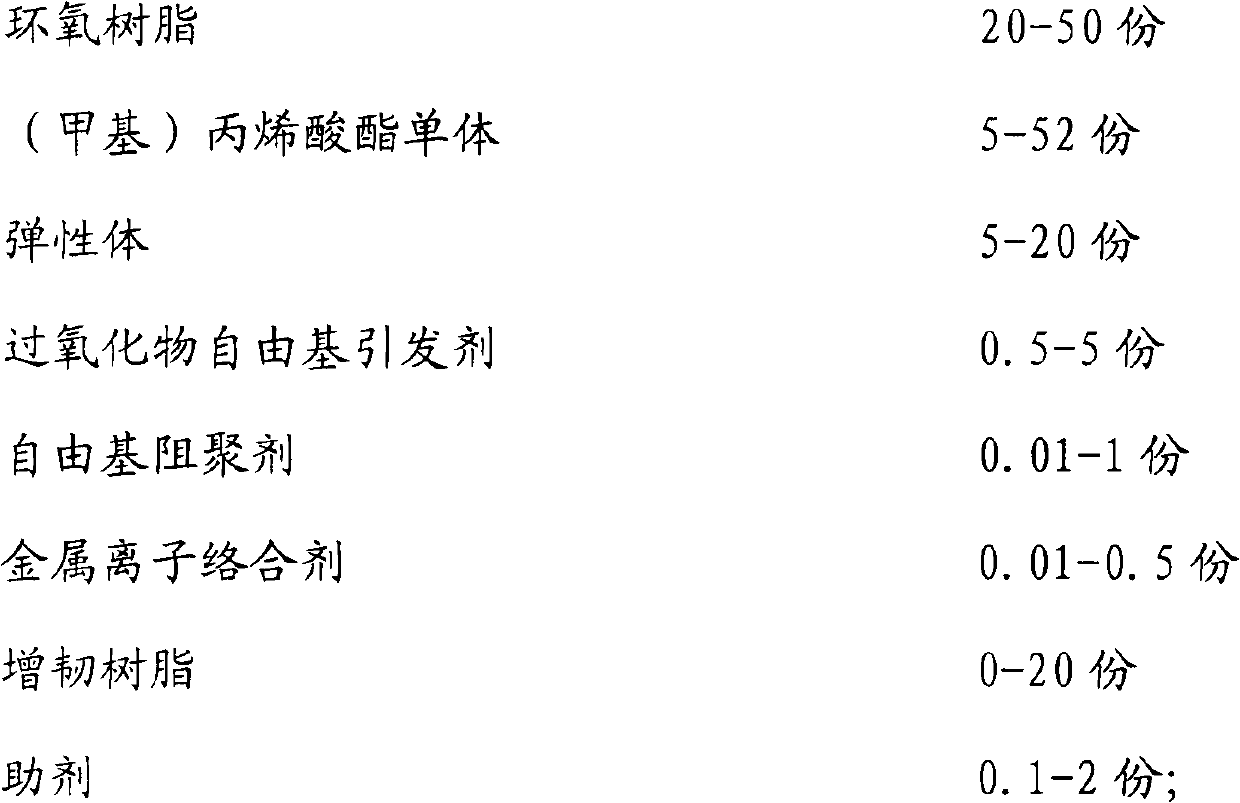

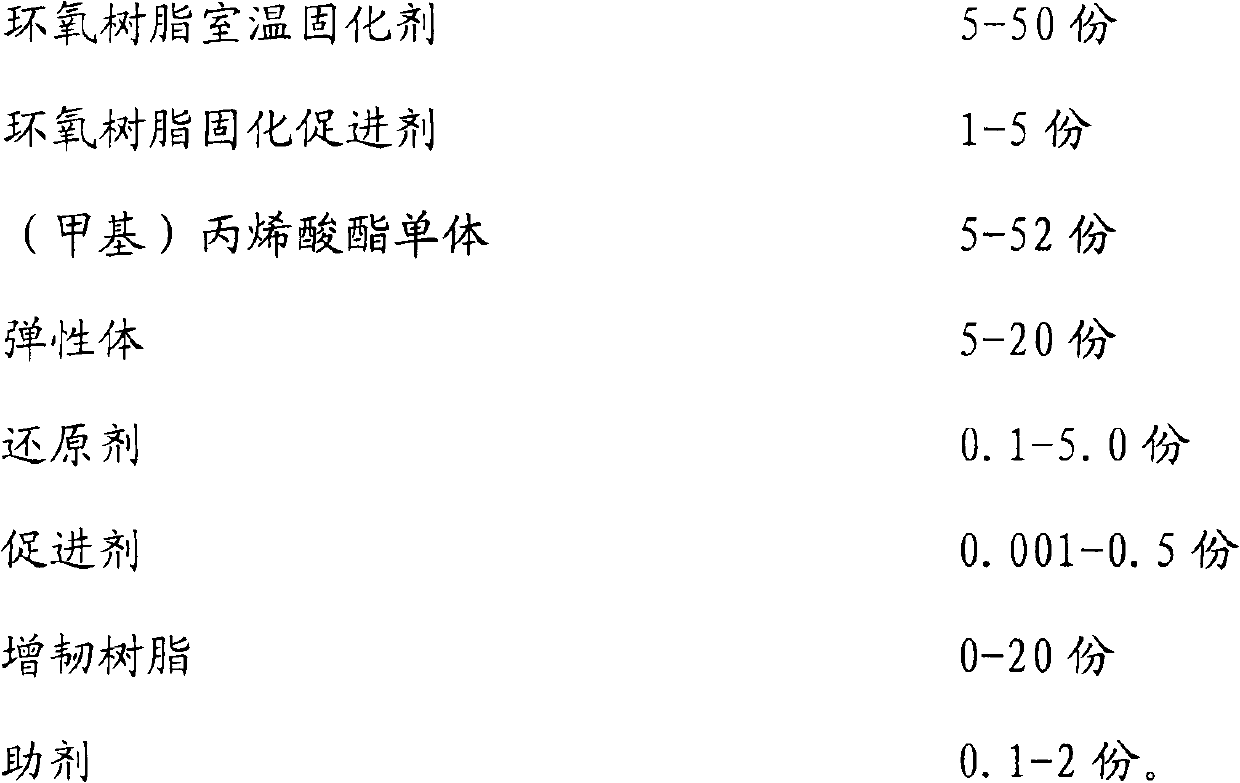

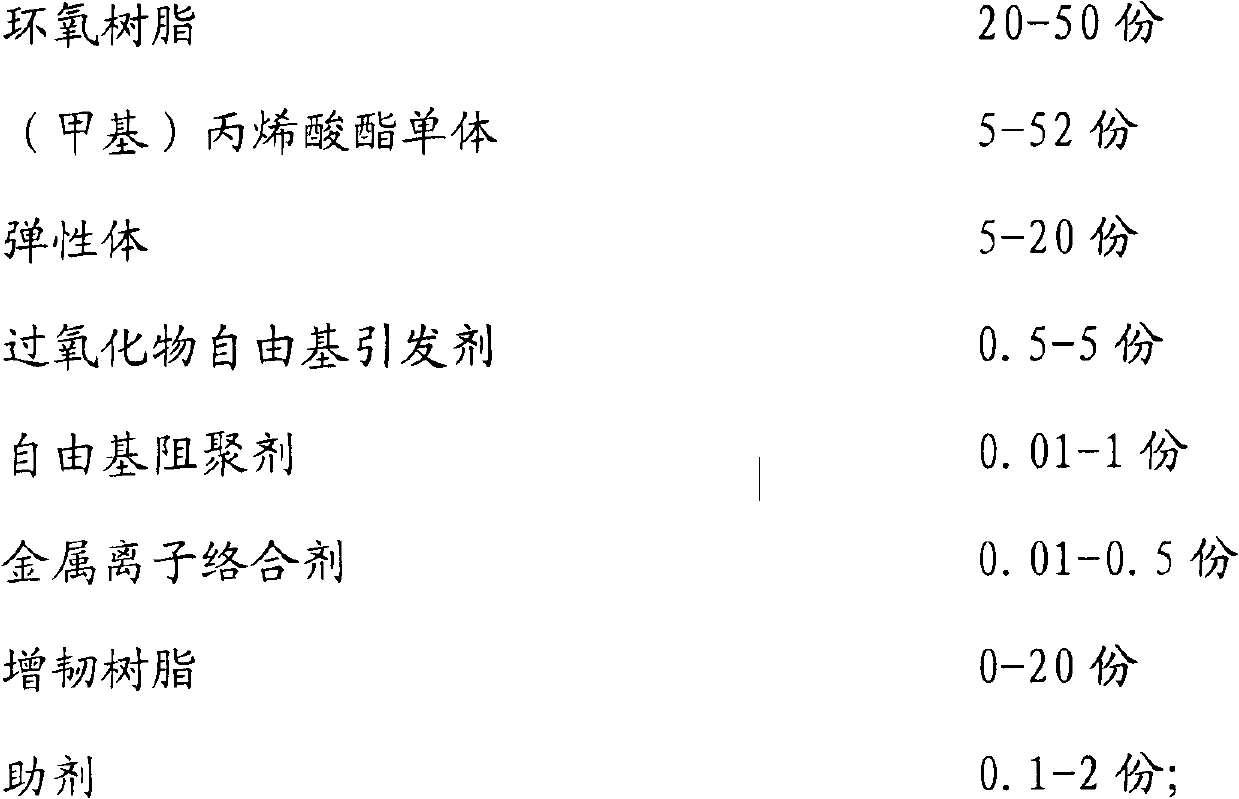

Method used

Image

Examples

Embodiment 1

[0038] Take 25Kg (meth)tetrahydrofuryl acrylate, 15Kg (meth)isobornyl acrylate, 12Kg hydroxyethyl methacrylate, 0.05Kg hydroquinone and 0.05Kg edetate disodium salt and stir for 15-30 minutes Mix evenly, control the temperature not to exceed 50°C; slowly add 5Kg nitrile rubber, 12Kg acrylonitrile-butadiene-styrene block copolymer during the stirring process, and stir until the nitrile rubber, acrylonitrile-butadiene - The styrene block copolymer is completely dissolved, and the temperature is controlled not to exceed 50°C; then add 28Kg E-51 epoxy resin, 0.5Kg silane coupling agent and stir for 15-30 minutes, the temperature is not higher than 50°C; cool down to 35°C Next, add 2.4Kg cumene hydrogen peroxide and stir for 15-30 minutes, the temperature is not higher than 35°C; cool down to below 30°C and vacuum to remove air bubbles to obtain component A, which can be stored at room temperature.

[0039] Take 25Kg tetrahydrofuryl methacrylate, 15Kg isobornyl methacrylate, 12.48K...

Embodiment 2

[0042] Take 19.99Kg N,N dimethylacrylamide, 2.5Kg multifunctional (meth)acrylate, 0.01Kg p-benzoquinone and 0.5Kg nitrilotriacetic acid and stir for 15-30 minutes to mix evenly, and control the temperature not to exceed 50°C ;After 5Kg of thermoplastic acrylate elastomer, stir until the thermoplastic acrylate elastomer is completely dissolved, and control the temperature not to exceed 50°C; add 50Kg of E-44 epoxy resin, 20Kg of polyurethane (meth)acrylate, and 1Kg of silane coupling agent, 1Kg defoamer, stir for 15-30 minutes, the temperature is not higher than 50°C; cool down to below 35°C, add 5Kg of benzoyl peroxide and stir for 15-30 minutes, the temperature is not higher than 35°C; cool to below 30°C Vacuumize to remove air bubbles to obtain component A, which can be stored at room temperature.

[0043]Take 19.5Kg N, N dimethylacrylamide and 6.5Kg multifunctional (meth)acrylate and stir for 15-30 minutes to mix evenly, and control the temperature not to exceed 50°C; then ...

Embodiment 3

[0046] Take 25Kg polyethylene glycol diacrylate, 26.39Kg ethoxylated bisphenol A diacrylate, 1Kg2,6-di-tert-butyl-4-methylphenol and 0.01Kg diethylenetriaminepentaacetic acid and stir for 15-30 minutes Mix evenly, control the temperature not to exceed 50°C; slowly add 8Kg chloroprene rubber and 3Kg styrene-butadiene block copolymer during the stirring process, and stir until the neoprene and styrene-butadiene block copolymerization The substance is completely dissolved, and the temperature is controlled not to exceed 50°C; then add 26Kg E-20 epoxy resin, 10Kg polyether (meth)acrylate, 0.05Kg silane coupling agent, 0.05Kg adhesion promoter and stir for 15-30 minutes. The temperature is not higher than 50°C; cool down to below 35°C, add 0.5Kg methyl ethyl ketone peroxide and stir for 15-30 minutes, the temperature is not higher than 35°C; cool down to below 30°C and vacuumize to remove air bubbles to obtain component A, group A Portions can be stored at room temperature.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com