Fast-curing structural adhesive and preparation method thereof

A fast-curing, adhesive technology, applied in the direction of adhesives, non-polymer organic compound adhesives, etc., can solve the problems of poor moisture and heat aging resistance, large internal stress and large shrinkage rate of bonding parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

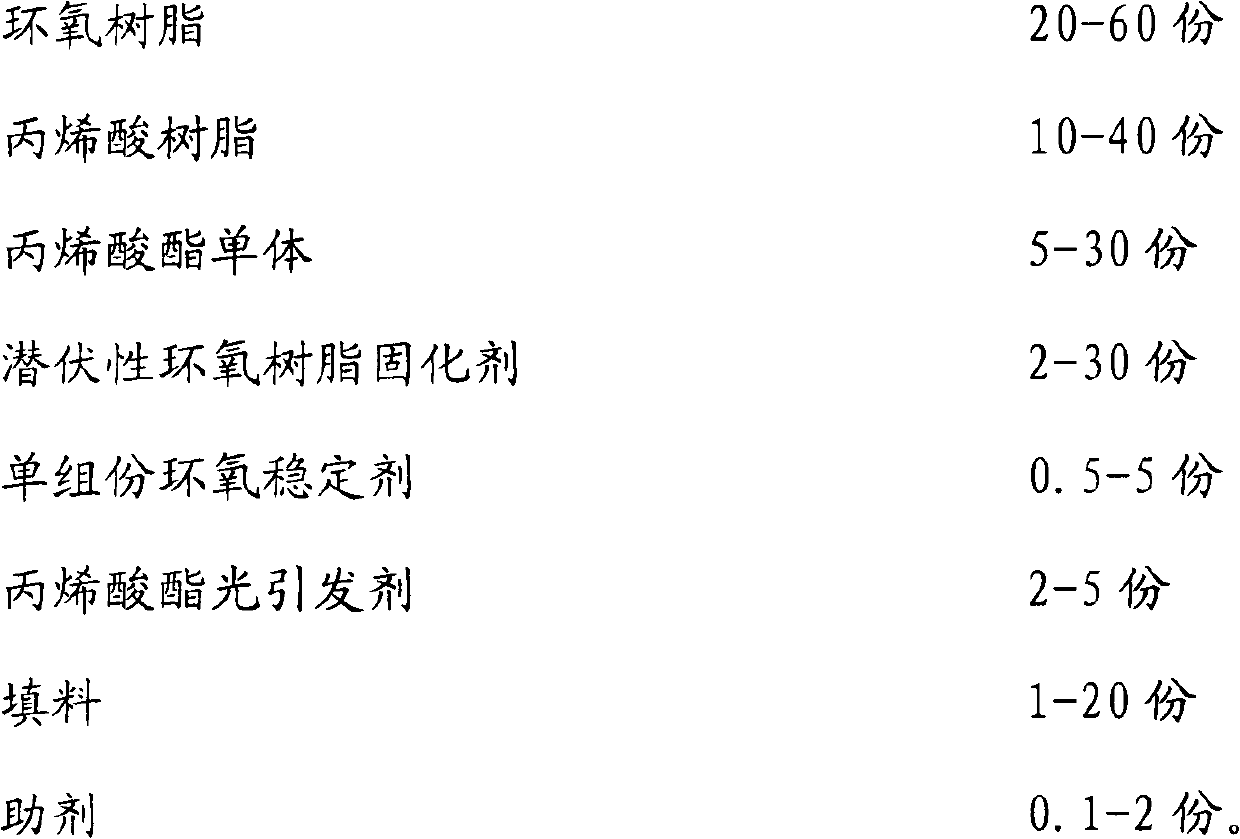

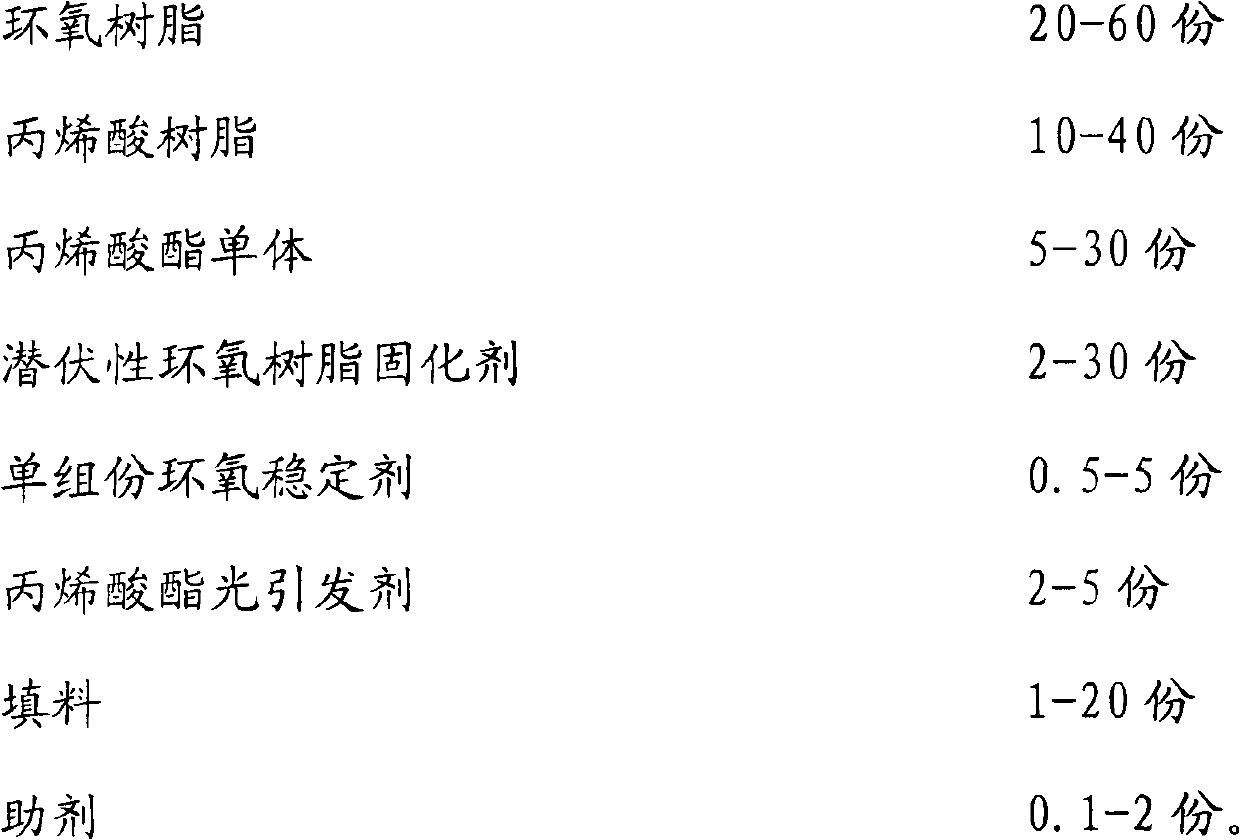

Method used

Image

Examples

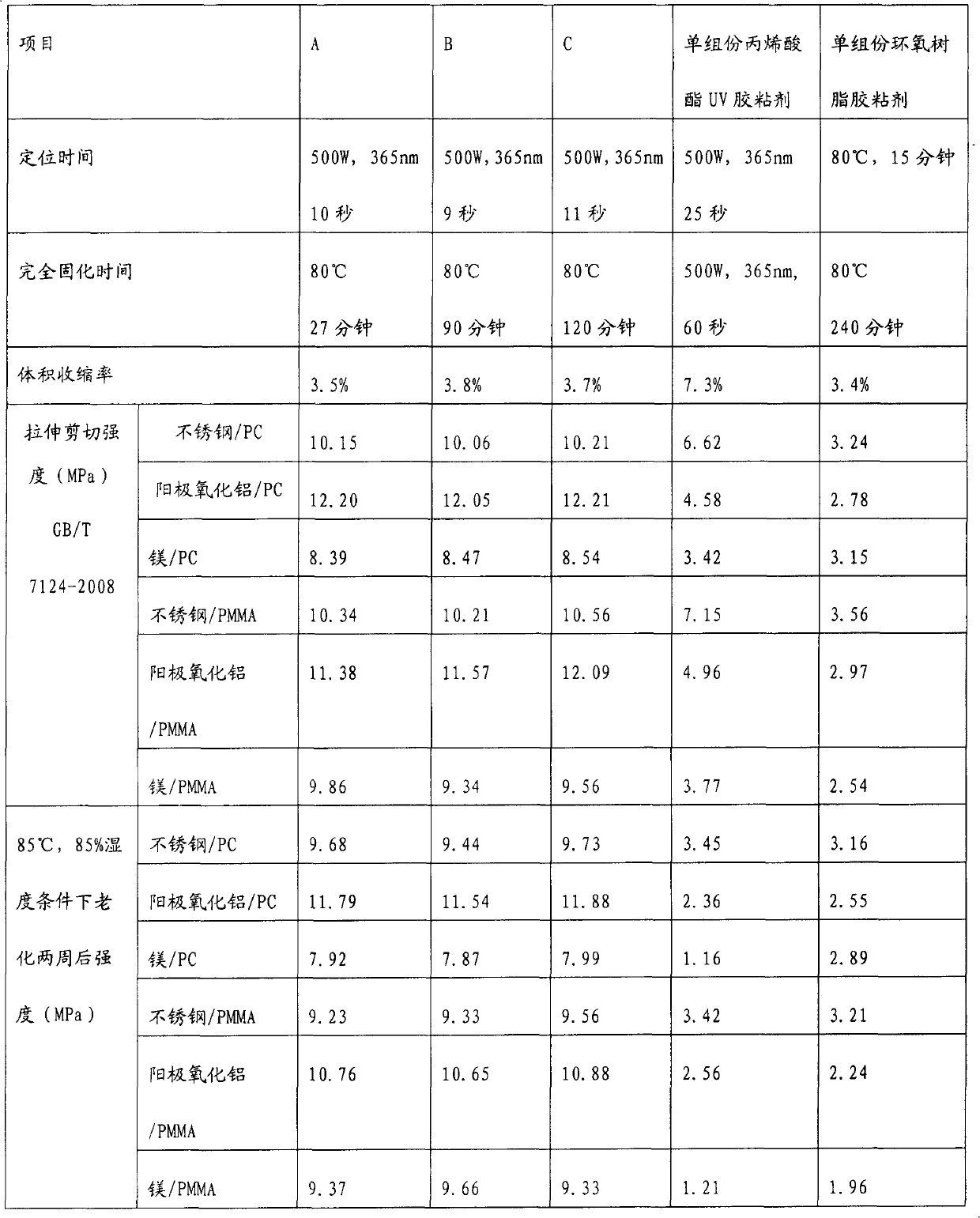

Embodiment 1

[0026] Take 25Kg urethane acrylate and 15Kg N,N dimethylacrylamide into the stirring tank and stir for 10-30 minutes until the mixture is uniform; after adding 2Kg 2,4,6-trimethylbenzoyl-diphenylphosphine oxide , heat up to 40°C, stir at high speed for 30-60 minutes until 2,4,6-trimethylbenzoyl-diphenylphosphine oxide is completely dissolved; then add 35.5Kg E-51 epoxy resin, 1Kg barbiturate in sequence Acid, 0.5Kg silane coupling agent and stir for 10-30 minutes until uniform, control the stirring temperature not to exceed 50°C; cool down to below 25°C, add 18Kg polythiol, stir at high speed for 30-60 minutes, disperse evenly, control the temperature during stirring The temperature does not exceed 25°C; add 3Kg of fumed silica and other fillers, stir at high speed for 15-30 minutes, control the stirring temperature not higher than 25°C, vacuumize to remove air bubbles, and control the temperature not to exceed 25°C to obtain the finished product A, packed in cans , The storag...

Embodiment 2

[0028] Add 10Kg of polyether acrylate and 30Kg of isobornyl (meth)acrylate into a stirring tank and stir for 10-30 minutes until they are evenly mixed; after adding 5Kg of benzophenone and substituted benzophenone, heat up to 30°C, Stir at high speed for 30-60 minutes until the benzophenone and substituted benzophenone are completely dissolved; then add 50.9KgE-44 epoxy resin, 0.5Kg barbituric acid, 0.1Kg epoxy resin system stabilizer and stir for 10- 30 minutes until uniform, control the stirring temperature not to exceed 50°C; cool down to below 25°C, add 2.5Kg boron trifluoride amine, stir at high speed for 30-60 minutes, disperse evenly, control the temperature during stirring to not exceed 25°C; add 1Kg Calcium carbonate and other fillers, stirred at high speed for 15-30 minutes, controlled stirring temperature not higher than 25°C, vacuumed to remove air bubbles, controlled temperature not exceeding 25°C, to obtain finished product B, canned, and the storage temperature o...

Embodiment 3

[0030] Take 40Kg of polyester acrylate and 5Kg of tetrahydrofuryl (meth)acrylate into the stirring tank and stir for 10-30 minutes until the mixture is uniform; Minutes until diethoxyacetophenone is completely dissolved; then add 36KgE-20 epoxy resin, 5Kg barbituric acid, 2Kg curing accelerator and stir for 10-30 minutes until uniform, control the stirring temperature not to exceed 50 °C; cool down to Below 25 degrees Celsius, add 2Kg of dimethylimidazole propylene oxide butyl ether adduct, stir at high speed for 30-60 minutes, disperse evenly, control the temperature during the stirring process not to exceed 25°C; add 5Kg of nano-alumina and other fillers, stir at high speed 15-30 minutes, control the stirring temperature not to be higher than 25°C, vacuumize to remove air bubbles, control the temperature not to exceed 25°C, and obtain the finished product C, which can be packed, and the storage temperature of the finished product should not be higher than 5°C.

[0031] Table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com