Method for producing total-eucalyptus plywood by adopting anticorrosive composite urea resin

A technology of compounding urea-formaldehyde resin and plywood, which is applied in the joining of wooden veneers, other plywood/plywood appliances, chemical instruments and methods, etc., can solve the problem of low corrosion resistance, perishability and insect resistance of all eucalyptus plywood To achieve the effect of reducing free formaldehyde content, white color, and good film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

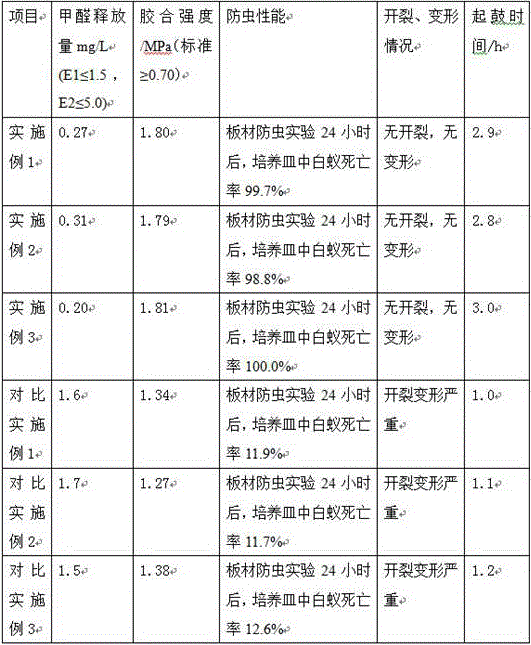

Examples

Embodiment 1

[0064] Adopt anticorrosion composite urea-formaldehyde resin to produce the method for full eucalyptus plywood, comprise the steps:

[0065] (1) Rotary slices of wood: Use a rotary cutter to cut eucalyptus into 1.5 mm thick slices to obtain eucalyptus veneers, and pick out unqualified boards with insect eyes, decay, and excessive defects;

[0066] (2) Veneer drying: Dry the eucalyptus veneer with a hot air stove, and control the moisture content of the veneer to be less than or equal to 10%;

[0067] (3) Gluing: Glue the eucalyptus veneer with a gluing machine, arrange 9 layers of glued eucalyptus veneer criss-cross and layered according to the wood texture structure, and glue them together to obtain a eucalyptus slab; The glue is anti-corrosion compound urea-formaldehyde resin, and the amount of glue on one side is 200g / m 2 ;

[0068] (4) Three times of cold pressing: the eucalyptus slab is cold pressed three times at a unit pressure of 0.8 MPa and at room temperature, each...

Embodiment 2

[0089] Adopt anticorrosion composite urea-formaldehyde resin to produce the method for full eucalyptus plywood, comprise the steps:

[0090] (1) Rotary slices of wood: Use a rotary cutter to cut eucalyptus into 1.5 mm thick slices to obtain eucalyptus veneers, and pick out unqualified boards with insect eyes, decay, and excessive defects;

[0091] (2) Veneer drying: Dry the eucalyptus veneer with a hot air stove, and control the moisture content of the veneer to be less than or equal to 10%;

[0092] (3) Gluing: Glue the eucalyptus veneers with a gluing machine, and arrange 11 layers of glued eucalyptus veneers in criss-cross layers according to the wood texture structure, and glue them together to obtain eucalyptus slabs; The glue is anti-corrosion compound urea-formaldehyde resin, and the amount of glue on one side is 220g / m 2 ;

[0093] (4) Three times of cold pressing: the eucalyptus slab is cold pressed three times at a unit pressure of 0.85 MPa and at room temperature,...

Embodiment 3

[0114] Adopt anticorrosion composite urea-formaldehyde resin to produce the method for full eucalyptus plywood, comprise the steps:

[0115] (1) Rotary slices of wood: Use a rotary cutter to cut eucalyptus into 1.5 mm thick slices to obtain eucalyptus veneers, and pick out unqualified boards with insect eyes, decay, and excessive defects;

[0116] (2) Veneer drying: Dry the eucalyptus veneer with a hot air stove, and control the moisture content of the veneer to be less than or equal to 10%;

[0117] (3) Gluing: Glue the eucalyptus veneers with a gluing machine and arrange 13 layers of glued eucalyptus veneers criss-cross and layered according to the wood texture structure, and glue them together to get eucalyptus slabs; The glue is anti-corrosion compound urea-formaldehyde resin, and the amount of glue on one side is 230g / m 2 ;

[0118] (4) Three times of cold pressing: the eucalyptus slab is cold pressed three times at a unit pressure of 0.9 MPa and at room temperature, ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com