Jointing glue for stone

A jointing glue and stone technology, applied in the field of stone jointing glue, can solve the problems of poor shrinkage resistance, dissatisfaction of joint filling, color difference, etc., and achieve the effects of strong shrinkage resistance, increased aesthetics, and good permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

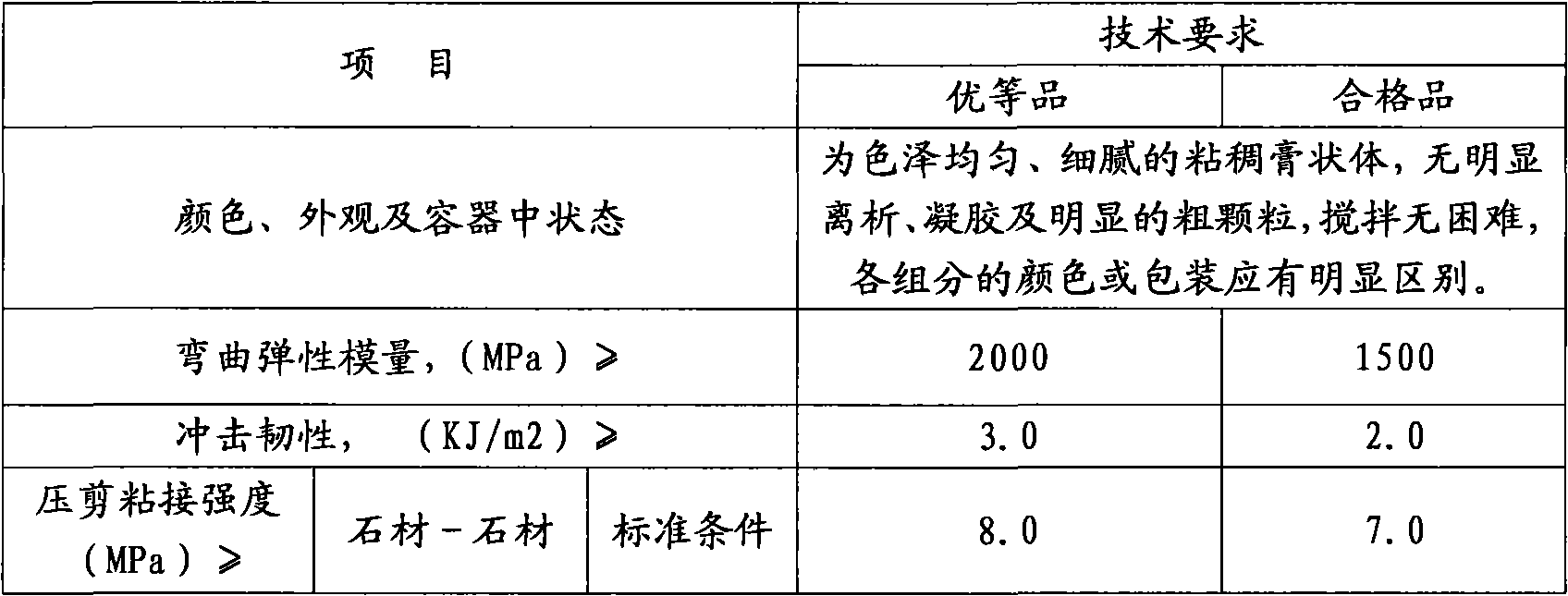

Image

Examples

Embodiment 1

[0037] Embodiment 1 (consumption is weight part)

[0038]Stone pointing glue is composed of 100 parts of air-drying unsaturated polyester resin, 5 parts of hydrogenated castor oil, and 15 parts of polyvinyl acetate (anti-shrinkage agent). The air-drying unsaturated polyester resin is a modified unsaturated polyester resin that synthesizes dicyclopentadiene by a half-esterification method.

[0039] After testing: its compressive shear strength (MPa) is: 14.8, tensile shear strength (MPa): 16.3, bending elasticity (MPa): 4435.0, impact toughness (KJ / m 2 ): 2.2, Hardness (HSD): 73.4, Shrinkage (%): 0.09.

[0040] When in use: the stone pointing glue of the present invention needs to be mixed with the curing agent and stirred evenly, and the mixing ratio of the stone pointing glue and the curing agent is 100:3

Embodiment 2

[0041] Embodiment 2 (consumption is weight part)

[0042] Stone pointing glue is composed of 100 parts of air-drying unsaturated polyester resin, 5 parts of hydrogenated castor oil, 10 parts of silicon dioxide with an average of 1000 mesh, and 15 parts of polyvinyl acetate (anti-shrinkage agent). The air-drying unsaturated polyester resin is a modified unsaturated polyester resin that synthesizes dicyclopentadiene by a half-esterification method.

[0043] After testing: its compressive shear strength (MPa) is: 16.4, tensile shear strength (MPa): 17.1, bending elasticity (MPa): 4085.6, impact toughness (KJ / m 2 ): 3.0, Hardness (HSD): 71.0, Shrinkage (%): 0.05.

[0044] When in use: the stone pointing glue of the present invention needs to be mixed with the curing agent and stirred evenly, and the mixing ratio of the stone pointing glue and the curing agent is 100:3

Embodiment 3

[0045] Embodiment 3 (consumption is weight part)

[0046] Stone pointing glue consists of 100 parts of air-drying unsaturated polyester resin, 1 part of hydrogenated castor oil, 60 parts of silicon dioxide with an average of 300 meshes, 1 part of polystyrene (anti-shrinkage agent), diallyl phthalate 3 parts of ester, 1 part of styrene, 1 part of α-methylstyrene (reactive diluent). The air-drying unsaturated polyester resin is allyl glycidyl ether modified unsaturated polyester resin.

[0047] After testing: its compressive shear strength (MPa) is: 14.7, tensile shear strength (MPa): 15.6, bending elasticity (MPa): 4673.2, impact toughness (KJ / m 2 ): 2.61, Hardness (HSD): 64.5, Shrinkage (%): 2.63.

[0048] Using method is the same as embodiment 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com