Aqueous polyaniline anti-corrosive paint and preparation method thereof

A technology of water-based polyaniline and anti-corrosion coatings, applied in the field of coatings, can solve problems such as human harm and environmental pollution, and achieve excellent water resistance and anti-corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The invention provides a kind of preparation method of waterborne polyaniline anticorrosion coating:

[0058] 1) Preparation of component A:

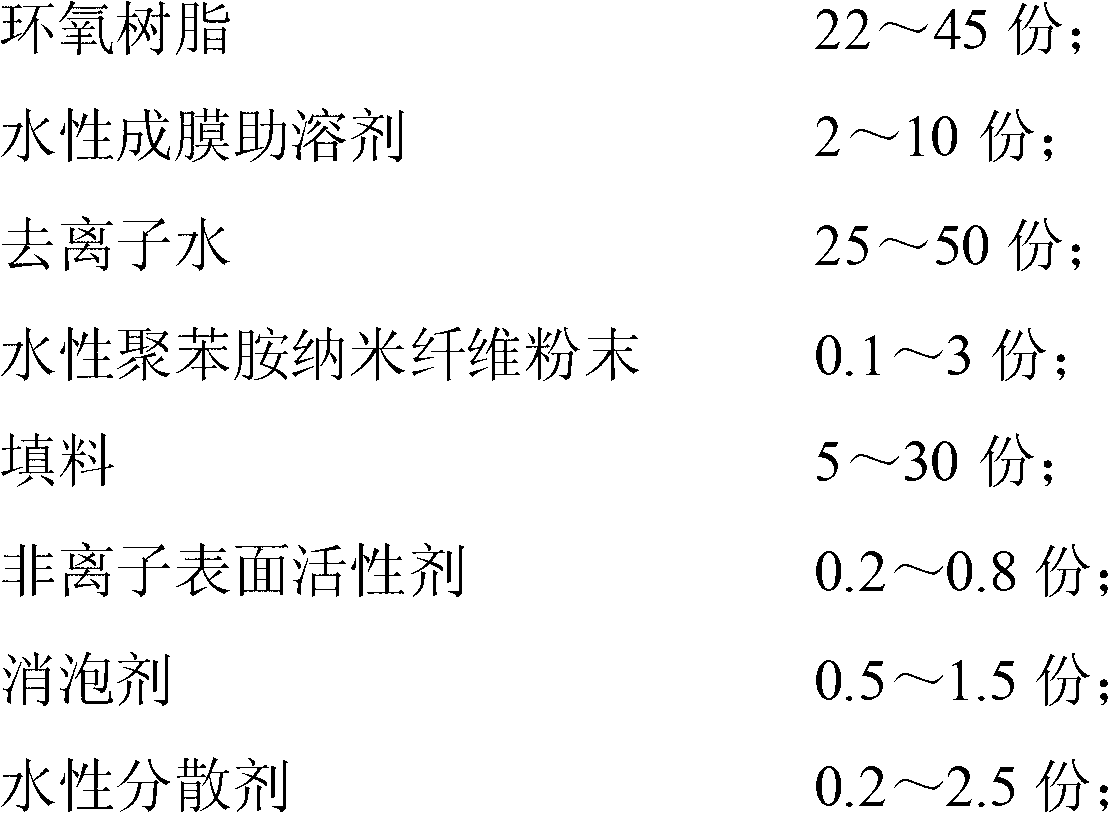

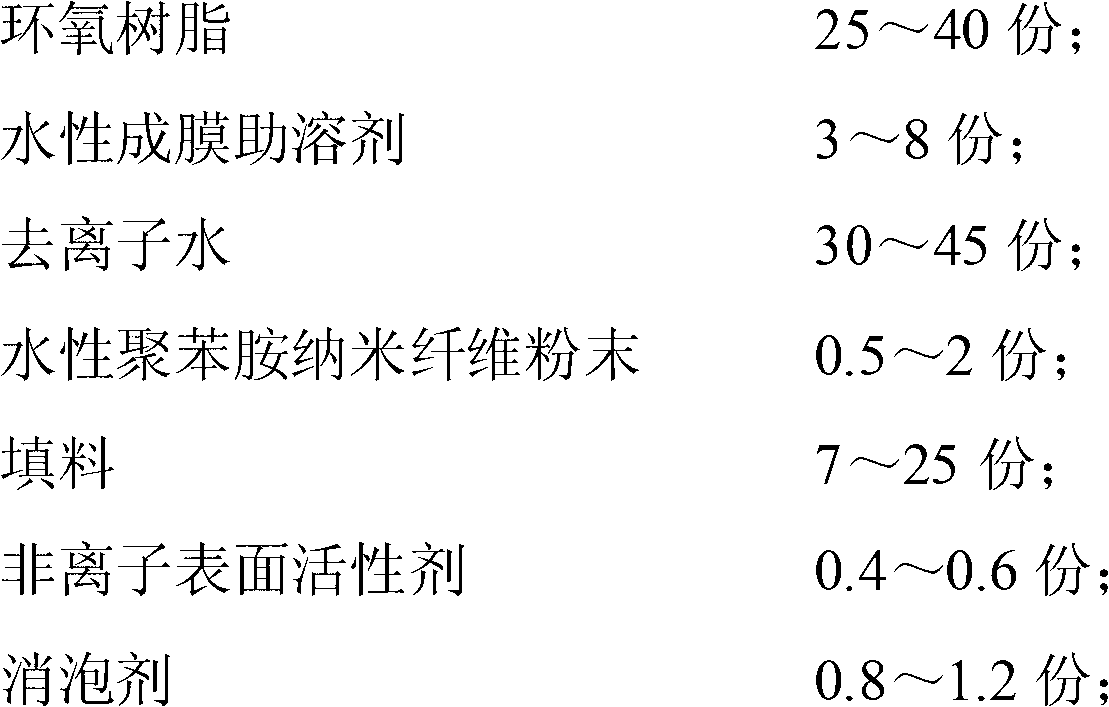

[0059] Add epoxy resin, water-based film-forming co-solvent, water-based polyaniline nanofiber powder and deionized water into the sand mill tank, stir at a speed of 1200-2000rpm for 1-3 hours, sand mill for 0.5-2 hours, and then, Add fillers, non-ionic surfactants, defoamers and water-based dispersants, continue sanding for 3 to 5 hours, and filter with 200-mesh filter cloth to obtain coating A component;

[0060] 2) Preparation of component B:

[0061] Stir the water-based curing agent, deionized water, and leveling agent in a sand mill tank at a speed of 1800-2500rpm for 0.5-2 hours, and filter with a 200-mesh filter cloth to obtain component B of the coating;

[0062] 3) Mix component A obtained in step 1) with component B obtained in step 2) in a weight ratio of 2 to 12:1 to obtain a water-based polyaniline anti-corrosion ...

Embodiment 1

[0073] 1) Preparation of component A:

[0074] Add 26 grams of epoxy resin E44, 2.6 grams of water-based film-forming co-solvent ethylene glycol butyl ether, 0.1 grams of water-based conductive polyaniline nanofiber powder (average fiber diameter 19nm) and 30 grams of deionized water into the sand mill tank , stirred at 2000 rpm for 1.5 hours, then sanded for 1 hour. Then, add 1.5 grams of talcum powder, 3.5 grams of precipitated barium sulfate, 2.5 grams of calcium carbonate, 0.2 grams of nonionic surfactant OP-10, 0.8 grams of defoamer BYK055 and 0.5 grams of dispersant BYK163, and continue sanding for 4 hours. 200 mesh filter cloths were filtered to obtain the coating A component.

[0075] 2) Preparation of component B:

[0076] Stir 40 grams of water-based curing agent H202B, 32 grams of deionized water, and 1.5 grams of leveling agent BYK366 in a sand mill tank at a speed of 1800 rpm for 1.5 hours, and filter through a 200-mesh filter cloth to obtain component B of the ...

Embodiment 2

[0080] 1) Preparation of component A:

[0081] Add 45 grams of epoxy resin E51, 10 grams of water-based film-forming co-solvent diethylene glycol butyl ether, 3 grams of water-based conductive polyaniline fiber powder (average fiber diameter, 22nm) and 50 grams of deionized water into the sand mill tank , stirred at 1200 rpm for 3 hours, then sanded for 2 hours. Then, add 12.5 grams of talcum powder, 10.5 grams of precipitated barium sulfate, 7 grams of calcium carbonate, 0.8 grams of nonionic surfactant Span-60, 1.5 grams of defoamer BYK088 and 2.5 grams of dispersant BYKP-105, and continue sanding for 5 hours , and filtered with a 200-mesh filter cloth to obtain component A of the coating.

[0082] 2) Preparation of component B:

[0083] Stir 65 grams of water-based curing agent H206B, 62 grams of deionized water, and 5 grams of leveling agent BYK333 in a sand mill jar at a speed of 2500 rpm for 2 hours, and filter with a 200-mesh filter cloth to obtain component B of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com