Novel inorganic intumescent steel structure fireproof coating and preparation method thereof

A technology for fire-resistant coatings and steel structures, applied in the direction of fire-resistant coatings, alkali metal silicate coatings, coatings, etc., can solve the problems of reduced fire-proof performance, coating cracking, and poor expansion of coatings, and achieve excellent high-temperature foam insulation Effects of thermal fire resistance, same-life weather resistance and aging resistance, and excellent high-temperature expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1: This example is the effect of using liquid sodium silicate alone on the film-forming and fire-proof performance of fireproof coatings, and the film-forming properties of liquid sodium silicate with a modulus of 1.5, 2.0, 2.5, 3.0, and 3.3 are studied , and the film-forming properties of the samples are shown in Table 1.

[0047] Table 1 The influence of liquid sodium silicate modulus on the film-forming properties of coatings

[0048]

[0049] It can be seen from Table 1 that when the low-modulus liquid sodium silicate is used as a film-forming agent, the curing time is longer, and when the modulus is 1.5, the curing time is greater than 96h, and the curing time decreases with the increase of the liquid sodium silicate modulus , when the modulus reaches above 3.0, the curing time is only 2 hours, but because the high modulus sample dries too fast, it will wrinkle, which is not conducive to film formation, and it is easy to crack during the burning process,...

Embodiment 2

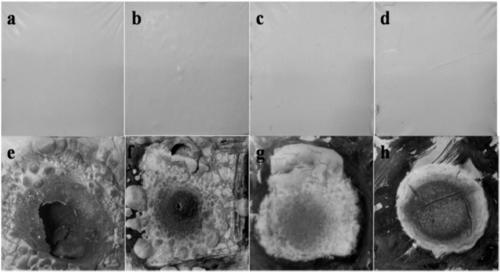

[0054] Embodiment 2: This embodiment is the influence of using the modulus of solid sodium silicate alone on the film-forming property of the coating: in order to devote oneself to the coating of preparing a kind of pure solid phase, it is 1.0, 2.0, 2.5, 3.3 to the solid silicon of modulus The film-forming properties of sodium bicarbonate were studied, and its film-forming performance and sample appearance are shown in Table 2 and image 3 shown.

[0055] Table 2 The influence of solid sodium silicate modulus on the film-forming properties of coatings

[0056] modulus

[0057] From Table 2, image 3 It can be seen that image 3 Among them, a, b, c, and d correspond to the modulus 1.0, 2.0, 2.5, and 3.3 respectively. Except for the solid sodium silicate with a modulus of 1.0, when the solid sodium silicate with other moduli is used as a film-forming agent, severe cracking occurs. phenomenon, and the larger the modulus, the more obvious the cracking phenomenon of th...

Embodiment 3

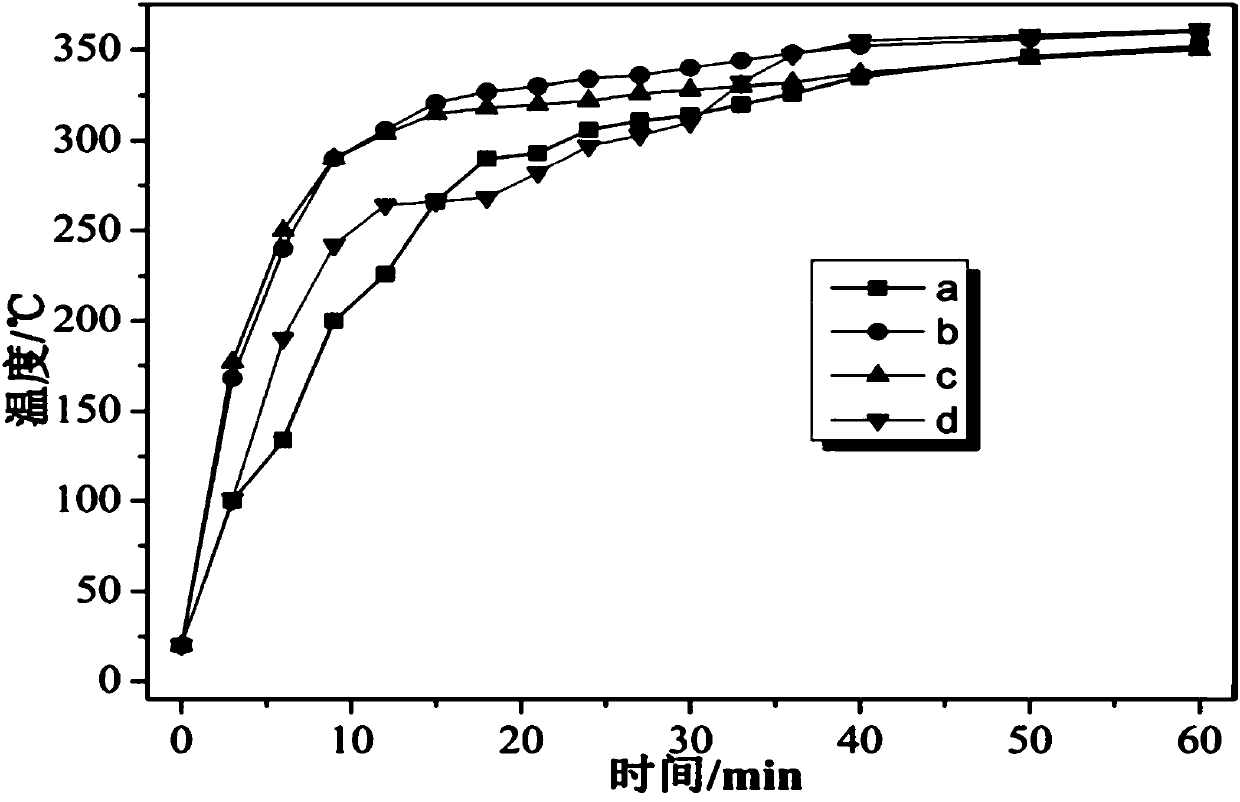

[0058] Embodiment 3: This embodiment is the influence of the mixing ratio of solid-liquid sodium silicate on the film-forming performance and fire resistance of fireproof coatings. Sodium silicate is the most ideal inorganic film-forming agent, but it can be seen from Examples 1 and 2 that, Whether liquid sodium silicate or solid sodium silicate is used as a film-forming agent alone, there are some shortcomings. In order to make the film-forming property and fireproof performance of the coating the best, but also to reduce the water content as much as possible (due to the In the process of water, the volume shrinkage of the sample will cause cracking), so this embodiment analyzes according to the above-mentioned experimental results, selects the liquid sodium silicate with a modulus of 3.0 as the main, and a small amount of solid sodium silicate with a modulus of 1.0 as an auxiliary. Solid-liquid mixed sodium silicate is used as a film-forming agent for fire-resistant coatings ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com