Fluorine and silicon-containing polyurethane prepolymer-modified epoxy resin and preparation method thereof

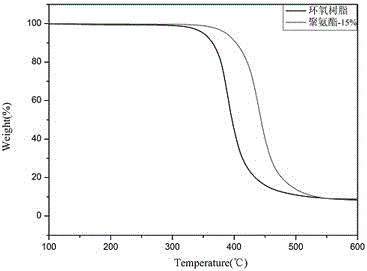

A polyurethane prepolymer and epoxy resin technology, which is applied in the field of resin composite materials, can solve the problems of poor toughening effect, reduced cross-linking degree, restriction of chain segment movement, etc., and achieves good toughening effect and good thermal stability. , the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

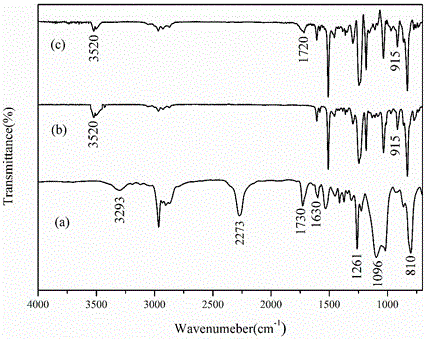

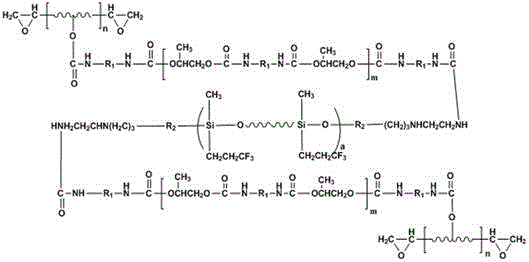

Method used

Image

Examples

Embodiment 1

[0030] (1) Add 80g D to a 500ml four-neck flask 3 F, 0.8g ethylenediamine, 0.4g H 2 O, at 60°C, turn on the nitrogen protection and stir for 10 hours, then raise the temperature to 100°C, and vacuumize for 1 hour to remove moisture and ethylenediamine. Heat and gradually add 29.6g of SCA-603 dropwise, keep the temperature at 60°C, and continue to react for 4 hours. After the reaction is completed, raise the temperature to 120°C, and vacuum for 2 hours;

[0031] (2) Take 22.2g of isoflurane diketone diisocyanate and add it to a four-necked flask, add 50g of polyoxypropylene diol with a molecular weight of 1000 drop by drop, raise the temperature to 75°C, add a drop of catalyst dibutyltin dilaurate, pass through N 2 , reacted for 3 hours; lowered the temperature to 40°C, added dropwise 1.332g of aminofluorosilicone oil in step (1), raised the temperature to 75°C, reacted for 80min, and stopped the reaction to obtain a fluorine-containing silicon polyurethane prepolymer.

[003...

Embodiment 2

[0042] (1) Add 40g D to a 500ml four-neck flask 3 F, 0.4g ethylenediamine, a drop of H 2 O, at 60°C, turn on the nitrogen protection and stir for 10 hours, then raise the temperature to 100°C, and vacuumize for 1 hour to remove moisture and ethylenediamine. Heat and gradually add 14.8g of SCA-603 dropwise, keep the temperature at 60°C, and continue to react for 4 hours. After the reaction is completed, raise the temperature to 120°C, and vacuum for 2 hours;

[0043] (2) Take 22.2g of isoflurane diketone diisocyanate and add it to a four-necked flask, add 55g of polyoxypropylene diol with a molecular weight of 1100 drop by drop, raise the temperature to 75°C, add a drop of catalyst dibutyltin dilaurate, and pass in N 2 , reacted for 3 hours; lowered the temperature to 40°C, added dropwise 1.332g of aminofluorosilicone oil in step (1), raised the temperature to 75°C, reacted for 80min, and stopped the reaction to obtain a fluorine-containing silicon polyurethane prepolymer.

...

Embodiment 3

[0047] (1) Add 80g D to a 500ml four-neck flask 3 F, 0.8g ethylenediamine, 0.4g H 2 O, at 60°C, turn on the nitrogen protection and stir for 10 hours, then raise the temperature to 100°C, and vacuumize for 1 hour to remove moisture and ethylenediamine. Heat and gradually add 29.6g of SCA-602 dropwise, keep the temperature at 60°C, and continue to react for 4 hours. After the reaction is completed, raise the temperature to 120°C, and vacuum for 2 hours;

[0048] (2) Take 22.2g of isoflurane diketone diisocyanate and add it to a four-necked flask, add 50g of polyoxypropylene diol with a molecular weight of 1000 drop by drop, raise the temperature to 75°C, add a drop of catalyst dibutyltin dilaurate, pass through N 2 , reacted for 3 hours; lowered the temperature to 40°C, added dropwise 1.332g of aminofluorosilicone oil in step (1), raised the temperature to 75°C, reacted for 80min, and stopped the reaction to obtain a fluorine-containing silicon polyurethane prepolymer.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com